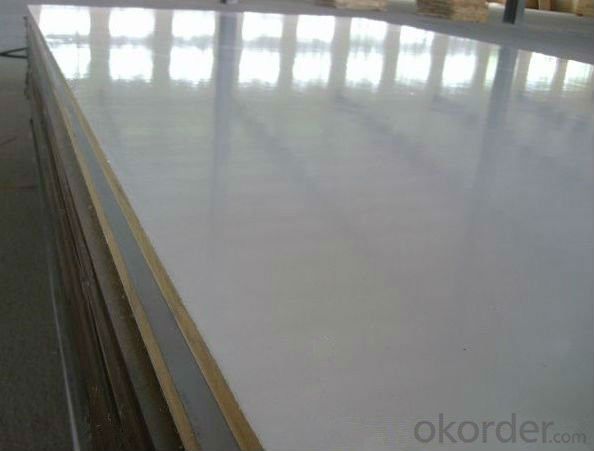

POLYESTER FACED PLYWOOD OVERLAY PLYWOOD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Polyester Plywood

Good Quality & Price

1)Color: solid color, wood grain or marble grain

2)Core: poplar, hardwood, combi

Product Description:

Product Name | COLORFUL POLYESTER PLYWOOD MELAMINE FACED PLYWOOD | |||||

Size | 1220x2440mm, 915x2135mm or as clients requirement | |||||

Thickness | 3~25mm | |||||

Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | |||||

Face/Back | Wood veneer laminated first, then one side or both side melamine laminated | |||||

Surface Treatment | Matt, textured or glossy | |||||

HPL Color | Gray white (There also have other more than 300 kinds color available: solid color (such as black, red, blue, orange, green, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, ect.) & marble grain.) | |||||

HPL Thickness | 0.5~1mm | |||||

Core | Poplar, hardwood, eucalypt, okoume, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Glue | E0, E1, E2, MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | HPL faced plywood is widely used for furniture, cabinet and interior decoration. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’ FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Delivery | loading in 7-10 days or shorter by clients special request.x | |||||

FEATURES:

High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

FAQ:

1.Free samples are avaliable

2.Delivery time:20days after getting deposit

3.Payment terms:T/T or L/C at sight

- Q:Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q:What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q:Plywood in the decoration works how to use

- . With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q:Why is the plywood commonly used in the singular layer

- and the back of the stripes) from the beautiful and do not look good

- Q:Judging wood is the standard for plywood

- Rare wood is only used to make very upscale furniture, and is often used in combination with lower-priced wood

- Q:Wood board, plywood, MDF What is the difference

- Blockboard is the core board made of wood board stitching, the two surfaces for the sticky wood veneer solid plate. Veneer, also known as the table, below the board by the board of a board said plate.

- Q:The basic principle of plywood

- are symmetrical. In the same plywood, you can use a single tree and veneer thickness, you can also use different tree species and thickness of the veneer

- Q:Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q:Solid wood and plywood which is better?

- the difference between selection: multi-layer solid wood flooring due to take into account the different species of "alternative heterosexual", so that the production process can fully balance the "internal stress"

- Q:How do I determine if plywood contains formaldehyde?

- Those who claim real real wood furniture, which often possession of plywood.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

POLYESTER FACED PLYWOOD OVERLAY PLYWOOD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords