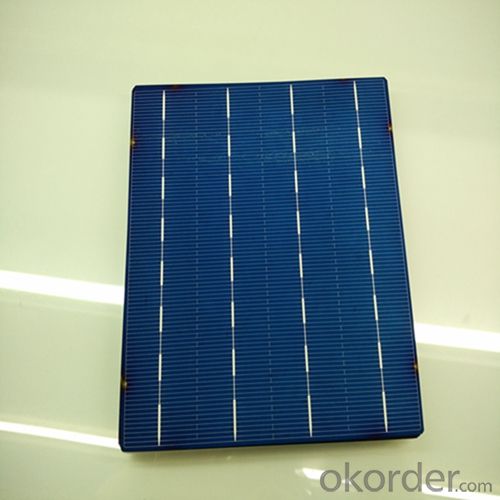

Poly 156X156mm2 Solar Cells Made in Class 2BB

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3999 watt

- Supply Capability:

- 6000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The operation of a photovoltaic (PV) cell requires 3 basic attributes:

The absorption of light, generating either electron-hole pairs or excitons.

The separation of charge carriers of opposite types.

The separate extraction of those carriers to an external circuit.

In contrast, a solar thermal collector supplies heat by absorbing sunlight, for the purpose of either direct heating or indirect electrical power generation from heat. A "photoelectrolytic cell" (photoelectrochemical cell), on the other hand, refers either to a type of photovoltaic cell (like that developed by Edmond Becquerel and modern dye-sensitized solar cells), or to a device that splits water directly into hydrogen and oxygen using only solar illumination.Characteristic of Mono 156X156MM2 Solar Cells

You are gaining energy independence - add battery backup power for even greater energy security

The cost of electricity is only going to rise – insure against that rising cost

Adaptive cells change their absorption/reflection characteristics depending to respond to environmental conditions. An adaptive material responds to the intensity and angle of incident light. At the part of the cell where the light is most intense, the cell surface changes from reflective to adaptive, allowing the light to penetrate the cell. The other parts of the cell remain reflective increasing the retention of the absorbed light within the cell.[67]

In 2014 a system that combined an adaptive surface with a glass substrate that redirect the absorbed to a light absorber on the edges of the sheet. The system also included an array of fixed lenses/mirrors to concentrate light onto the adaptive surface. As the day continues, the concentrated light moves along the surface of the cell. That surface switches from reflective to adaptive when the light is most concentrated and back to reflective after the light moves along

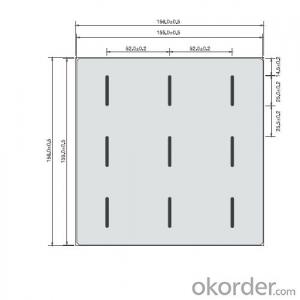

Mechanical data and design

Format | 156mm x 156mm±0.5mm |

Thickness | 210μm±40μm |

Front(-) | 1.5mm bus bar (silver),blue anti-reflection coating (silicon nitride) |

Back (+) | 2.5mm wide soldering pads (sliver) back surface field (aluminium) |

Temperature Coefficient of Cells

Voc. Temp.coef.%/K | -0.35% |

Isc. Temp.coef .%/K | +0.024%/K |

Pm.Temp.coef. %/K | -0.47%/K |

Electrical Characteristic

Effiency(%) | Pmpp(W) | Umpp(V) | Impp(A) | Uoc(V) | Isc(A) | FF(%) |

18.35 | 4.384 | 0.526 | 8.333 | 0.63 | 8.877 | 78.39% |

18.20 | 4.349 | 0.526 | 8.263 | 0.63 | 8.789 | 78.54% |

18.05 | 4.313 | 0.525 | 8.216 | 0.63 | 8.741 | 78.32% |

17.90 | 4.277 | 0.524 | 8.161 | 0.625 | 8.713 | 78.04% |

17.75 | 4.241 | 0.523 | 8.116 | 0.625 | 8.678 | 77.70% |

17.60 | 4.206 | 0.521 | 8.073 | 0.625 | 8.657 | 77.36% |

17.45 | 4.170 | 0.519 | 8.039 | 0.625 | 8.633 | 76.92% |

17.30 | 4.134 | 0.517 | 8.004 | 0.625 | 8.622 | 76.59% |

17.15 | 4.096 | 0.516 | 7.938 | 0.625 | 8.537 | 76.80% |

17.00 | 4.062 | 0.512 | 7.933 | 0.625 | 8.531 | 76.18% |

16.75 | 4.002 | 0.511 | 7.828 | 0.625 | 8.499 | 75.34% |

16.50 | 3.940 | 0.510 | 7.731 | 0.625 | 8.484 | 74.36% |

FAQ

FAQ

Q: What price for each watt?

A: It depends on the quantity, delivery date and payment terms, generally Large Quantity and Low Price

Q: What is your size for each module? Can you tell me the Parameter of your module?

A: We have different series of panels in different output, both c-Si and a-Si. Please take the specification sheet for your reference.

Q: What is your size for each module? Can you tell me the Parameter of your module?

A: We have different series of panels in different output, both c-Si and a-Si. Please take the specification sheet for your reference.

A solar cell is an electronic device which directly converts sunlight into electricity. Light shining on the solar cell produces both a current and a voltage to generate electric power. This process requires firstly, a material in which the absorption of light raises an electron to a higher energy state, and secondly, the movement of this higher energy electron from the solar cell into an external circuit. The electron then dissipates its energy in the external circuit and returns to the solar cell. A variety of materials and processes can potentially satisfy the requirements for photovoltaic energy conversion, but in practice nearly all photovoltaic energy conversion uses semiconductor materials in the form of a p-n junction.

The basic steps in the operation of a solar cell are:

the generation of light-generated carriers;

the collection of the light-generated carries to generate a current;

the generation of a large voltage across the solar cell; and

the dissipation of power in the load and in parasitic resistances.

Solar cells are structured in layers with different functions. The working principle is the same as in semiconductors.

The main part of a silicon (Si) solar cell generating solar power is formed by two differently doped (n- and p-) silicon layers. A physical barrier is created between them along the p-/n- junction, with electrons and holes diffusing into regions of lower concentration.

This depleted region or space charge region can only be overcome with the help of photons i.e. sunlight.

To be able to channel electrones and holes and generate electric power, metal contacts need to be printed onto the front and rear side. Generally, a full aluminium or silver layer is screenprinted onto the rear. A thin grid forms the front contact keeping the impact on light entering the silicon cells as low as possible.

To reduce light reflection, a thin film of silicon nitride or titanium dioxide is coated onto the surface.

- Q:What is the history of solar cell development?

- The history of solar cell development dates back to the 19th century when French physicist Alexandre-Edmond Becquerel discovered the photovoltaic effect, which is the basis for solar cell technology. However, it was not until the 1950s that the first practical solar cells were developed, primarily for use in space exploration. Over the years, advancements in materials and manufacturing techniques have led to improved efficiency and affordability of solar cells. Today, solar cells are widely used to generate clean and renewable energy for various applications, ranging from powering homes and buildings to providing electricity in remote areas. Ongoing research and development continue to push the boundaries of solar cell technology, aiming to enhance efficiency, durability, and accessibility to harness the sun's energy more effectively.

- Q:Can solar cells be used in underwater applications?

- Yes, solar cells can be used in underwater applications. However, special considerations need to be taken into account, such as protecting the cells from water damage and optimizing their performance in low light conditions. Waterproof enclosures and specialized coatings can help ensure the durability and efficiency of solar cells in underwater environments.

- Q:Can solar cells be used for off-grid applications?

- Yes, solar cells can be used for off-grid applications. Solar cells, also known as photovoltaic (PV) cells, convert sunlight into electricity. This renewable energy source can be harnessed to power various off-grid applications such as remote homes, cabins, or even portable devices. By installing solar panels and storage batteries, off-grid systems can generate and store electricity for use when there is no access to a traditional power grid.

- Q:Can solar cells be integrated into building materials?

- Yes, solar cells can be integrated into building materials. This practice, known as building-integrated photovoltaics (BIPV), involves embedding solar cells into various architectural elements such as windows, roofs, or facades. BIPV allows for the generation of renewable energy without the need for additional structures, maximizing energy efficiency and aesthetic integration within buildings.

- Q:Can solar cells be used for powering electric vehicle charging stations?

- Yes, solar cells can be used for powering electric vehicle charging stations. Solar panels can convert sunlight into electricity, which can then be used to charge electric vehicles. This renewable energy source is ideal for charging stations as it reduces reliance on traditional power grids and reduces carbon emissions.

- Q:Can solar cells be used on satellites?

- Yes, solar cells can be used on satellites. In fact, they are commonly used to power satellites in space by converting sunlight into electricity.

- Q:Can solar cells be combined with energy storage systems?

- Yes, solar cells can be combined with energy storage systems. This integration allows for the excess energy generated by solar cells to be stored for later use, such as during periods of low sunlight or at night. Energy storage systems, such as batteries, enable a more reliable and efficient utilization of solar energy, making it a feasible and sustainable solution for meeting energy demands.

- Q:Can solar cells be used for powering data centers?

- Yes, solar cells can be used to power data centers. Solar energy can be harnessed through photovoltaic panels to generate electricity which can then be used to power the infrastructure of data centers. This renewable energy source can help reduce the carbon footprint and dependency on fossil fuels, making data centers more sustainable and environmentally friendly.

- Q:Why should the solar cells be laserized?

- Extended reading: Through the practice of testing and manufacturers, Tuopu photoelectric laser etching technology summary, the results of the current solar photovoltaic industry using laser etching scribing technology P1 level using narrow pulse infrared nano-laser is the most ideal,

- Q:Can solar cells work in cloudy weather?

- Yes, solar cells can still generate electricity in cloudy weather, although their efficiency may be reduced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Poly 156X156mm2 Solar Cells Made in Class 2BB

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3999 watt

- Supply Capability:

- 6000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords