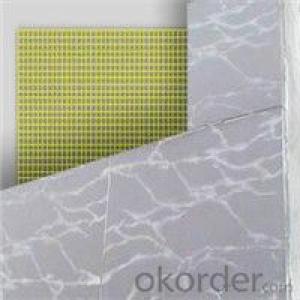

Plastic fiberglass mesh for mosaic with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fiberglass mesh

Description of glass fibre mesh

Alkali Resistant glass fibre mesh is made from C-glass, E-glass or AR-glass woven fabric then coated by acrylic acid copolymer liquid. This alkali-resistant mesh has excellent properties including water resistance, flexibility, softness, resistant to aging and attack from breakdown. It is widely used for waterproofing in roofing applications, reinforcement for natural marble, plasterboard, and Exterior Insulation Finishing Systems (EIFS).

Specifications of glass fibre mesh:

Mesh Size | Weight | Width | Length per Roll | Color |

(mm) | (gr/m2) | (cm) | (m) | |

5*5 | from 50 to 200 | from 20 to 200 | from 50 to 600 | All colors |

4*4 | from 75 to 200 | |||

4*5 | from 85 to 200 | |||

5*6 | from 75 to 200 | |||

10*10 | from 75 to 200 |

Applications of glass fibre mesh

The glass fibre alkali resistant mesh fabric is an ideal engineering material in construction with the following applications:

Exterior Insulation Finishing Systems (EIFS): Fiberglass alkali resistant mesh is an integral part of the structure in EIFS. The fiberglass mesh has high strength, good cohesion, and can combine with EPS board firmly. Moreover, it can resist alkaline properties of cement and other structural compounds.

Waterproof Roofing As the waterproof medium (bitumen) is weak itself the waterproof system is easily cracked due to temperature changes, sunlight and wind. When fiberglass mesh is added to the system it can strengthen the ability to resist this influence because of its properties of high tensile strength and alkali resistance

Stone Reinforcement Fiberglass mesh is ideal to reinforce and protect natural stone because if its high strength and balanced structure. It can spread weight transfer and stress equally and it is easily adhered to the back of materials such as marble, mosaics and other stone.

- Q:How do you paste the mesh cloth on the back of the stone?

- At the bottom of the stone board, besmear the resin glue, and then adhere to the fiber mesh cloth, forming tensile waterproof layer, but must not forget to brush in the side.

- Q:Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- 1, first of all, from the material, imitation gold pot mesh cloth, its warp is Kim Nabesa, weft is Tonabe Sa, this is called "imitation gold pot" mesh cloth one aspect.2, and then, imitation gold pan mesh cloth looks like the appearance of the gold pan mesh cloth is exactly the same, so it has become imitation gold pot.3, and finally, the quality of imitation gold pan mesh cloth can never be better than the quality of the gold pan mesh cloth, which is also called "imitation gold pot" one of the reasons.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

- Q:Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- Therefore, the first floor insulation system adopts double-layer grid cloth and thickening protection layer, so as to enhance the impact resistance capability of the external insulation system.

- Q:How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q:Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q:What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q:What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- The reason: the current domestic weaving factory method or pre roll beam weaving, and net fabric warp yarn and weft yarn is usually, roving, the intensity is greater than the warp weft. Secondly, to weave is usually weaving, woven to the continued strength of more than.

- Q:Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic fiberglass mesh for mosaic with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 g/m²

- Supply Capability:

- 10000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords