Phenolic Foam Boards Insulation 7CM FOR WALL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Closed cell phenolic foam is used extensively in the building industry for a number of application areas including roofing, cavity board, external wall board, plaster board dry linings systems, floor insulation and as sarking board. Phenolic foams offer significant advantages over other insulation materials which are summarised below. A range of phenolic foam boards is available to suit most new buildings or refurbishment applications.

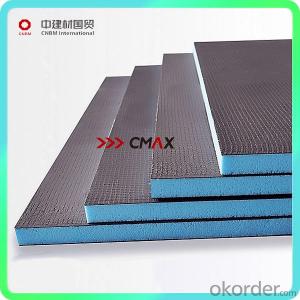

Phenolic foam boards used in the building industry are typically manufactured in the continuous lamination process. This involves spraying a mixture of phenolic resin, catalyst and blowing agent onto a moving facing. A top facing is then introduced and the product then goes through a heated conveyor press and heated ovens and is then cut to the required size. Phenolic foam products with Agrément certification are available for roofing, cavity board, floor board, dry lining, external wall board and sarking board.

ADVANTAGES

Space saving: the exceptionally low thermal conductivity of closed cell phenolic foam boards means that appropriate insulation efficiency can be achieved with the thinnest possible material. This can be a significant advantage in building regulations, for example, in plaster board dry lining systems where internal room space is maximised and in cavity wall applications where the building envelope thickness is minimised.

Features:

1) A new type of environmental protective plastic materials instead of woods and steels.

2) It is a flexible, economical, extremely versatile PVC-U sheet.

3) The fine cell structure and smooth surface finish makes it the preferred choice of professional printers and sign makers.

4) Light-weight, anti-flaming.

5) Alkali &acid resistance, moisture proof, water-proof, good heat preservation, sound insulation, shock absorption and so on.

6) The board can be filmed or printed colorfully

7) It owns many ways of processing such as nailing, sawing, planning, cementing, jointing and so on.

Construction:

1) Wall cladding & partitioning

2) Hygienic cladding

3) Decorative cladding

4) Temporary partitioning

5) False ceilings

6) Moulded panels.

DATA

(1) Petrochemical industry -- heat insulation and sound absorption of equipments for petroleum industry, power industry and chemical industry.

(2) Construction industry -- heat insulation and sound absorption of partition, curtain wall, roofs and fences for construction.

(3) Mining industry -- heat preservation and fireproof for industrial kiln, oven, large-caliber storage tank and shipping.

(4) Our product is widely used for the heat insulation and sound absorption and heat preservation of pipes in building fiel

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Panasonic refrigerator with the world's leading vacuum insulation material Vacuuminsulationpanel (referred to as VIP) vacuum insulation board, is developed in recent years, a new type of highly efficient insulation material, which uses vacuum insulation principle, under vacuum conditions, the thermal conductivity is very low , Widely used in household appliances. The product to fill the gaps, is a leading international high-tech products. . VIP in the production and application process does not use ODS substances. . the insulation layer of the same thickness, you can save energy. . the same energy consumption, VIP can reduce the thickness of the insulation layer to reduce the volume of objects, increase storage space. . VIP design engineers can provide a variety of flexible options. . CFC consumption of ozone, destruction of the ecological environment, if the alternative blowing agent, its high thermal conductivity, reducing the thermal insulation properties of the foam, although the environmental protection, but need to consume more energy, and VIP is environmentally friendly And the dual advantages of energy saving. . VIP on environmental protection and national energy conservation has a great contribution. . VIP thermal conductivity is PU one-eighth, is the replacement of insulation materials. Vacuum insulation panel (VIP) technology industry has quickly formed a practical industry trends, and industry-class enterprises to adopt. Was rated as energy-saving refrigerator model products which is the use of VIP technology to achieve energy-saving purposes. (BCD-239DVC), Panasonic "energy saving king" refrigerator (NR-E461U), the new energy-saving "Golden Eagle" refrigerator (BCD-218E) Meiling "digital energy-saving Wang" refrigerator (BCD-239DVC) BCD-200A / HC, BCD-270A / HC and other six models (BCD-219U / C), the best energy-saving refrigerators, including BCD-180A / HC, BCD-200A / HC, BCD-270A / HC and other six models Wait.

- Q:How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Extruded polystyrene board with XPS insulation board is no different, because it is the same thing two kinds of name. Extrusion polystyrene board full name is extruded polystyrene foam board, referred to as extruded plate, also known as XPS board, extruded polystyrene board. Extrusion polystyrene board use: 1 & gt; widely used in wall insulation, flat concrete roof and steel roof insulation; 2 & gt; for low temperature storage ground, parking platform, airport runway, highway and other areas of moisture insulation. Extruded plate is polystyrene resin supplemented by polymer in the heating and mixing at the same time, into the catalyst, and then extruded out of continuous closed-cell foam foam foam, the internal independent of the closed bubble structure, It is a kind of environment-friendly insulation material with high compression resistance, low moisture absorption, moisture-proof, airtight, light weight, corrosion resistance, super-aging resistance (almost no aging for long-term use) and low thermal conductivity. Extruded board is widely used in dry wall insulation, flat concrete roof and roof insulation of steel roof, low temperature storage floor, low temperature floor radiant heating heating pipe, parking platform, airport runway, highway and other areas of moisture insulation, Frost heave, is the construction industry inexpensive, excellent quality of the insulation, moisture-proof material.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q:Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Phenolic Foam Boards Insulation 7CM FOR WALL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords