BP Extruded Polystyrene Sheet CO2 Foam Board (XPS)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BP Extruded Polystyrene Sheet CO2 Foam Board (XPS)

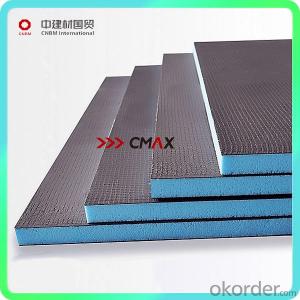

Extruded Polystyrene foam insulation board (BEIPENG) polystyrene resin as the main raw material, by a special process of continuous extrusion molding of rigid foam sheet under introduced production line, has a perfect closed cell structure.

The world's most advanced foaming(CO2) process is applied. Our products are more friendly to the environment.

It's widely used in wall insulation, cold storage, parking platforms, airport, railway, concrete roof construction, highways, and other areas of moisture-proof inexpensive decoration industry.

Advantages:

1. high compression resistance

2. moisture-proof

3. airtight

4. non-absorbent

5. corrosion resistance

6. low thermal conductivity

7. lightweight

8. Life time:60 years

9. environmentally friendly

Why Choose us?

1. We're the largest manufactuer and leader of this industry in China.

2. Various styles for you to choose.

3. High and stable quality with competitive price.

4. Short lead time.

5. Sample order or smaller quantity will be appreciated.

6. Best service will be offered to our clients.

Inquire us now and we'll not let you down.

Data Sheet:

| Technical Data Sheet | |||

| Extruded Sheet (XPS) | |||

| Model | ×200 ×250 ×350 | ×400 ×450 ×500 ×600 | ×650 ×700 ×800 |

| Thermal Conductivity w/mk | 0.026 0.027 0.030 0.032-0.035 | ||

| Dimensional Stability | 0.3-1.0 | ||

| Applicable Temperature | -50°C - +75°C | ||

| Compression Strength kpa | 200 250 350 400 450 500 600 650 700 800 | ||

| Water Absorption | 0.3-1.0 | ||

| Density kg/m3 | 30-33 33-36 36-40 43-53 | ||

| Combustion Performance | GB8624-2012 Grade A, Grade B1 and Grade B2 | ||

| Oxygen Index | IO26-33 | ||

| Length | 1200 1450 1800 2400 | ||

| Width | 600 1200 | ||

| Thickness | 5 10 20 25 30 40 50 60 70 80 90 100 120 | ||

| Edge Shape | SS Flat Top SL Lap Joint TG Tenon RC Rain Gutter | ||

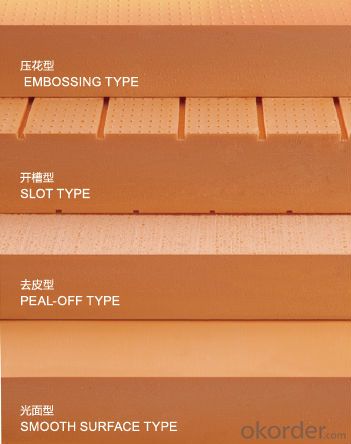

| Surface | Embossing Slotting Planing Smooth Surface | ||

| Applications | Insulation and Energy-Saving for Building Walls; Heat Preservation and Insulation for Cold Storage; Heat Preservation and Insulation for Roof; Stops and Side Panel on High-Speed Rail and Roads; Duct Pipe for Central Air Conditioner; Hydraulic Projects | Heat preservation and insulation for cold storage ground, steel-work roof, concrete roof construction; Frost-heave control for high-speed road, railway and airfield runway. | High-speed rail, CRTS track; Heavy cold storage ground. |

Surface Type:

Applications:

It's widely used in wall insulation, cold storage, parking platforms, airport, railway, concrete roof construction, highways, etc.

COMPANY PROFILE

Beijing BEIPENG New Building Materials Co., Ltd, established in 2000, which is a globally integrated company supply specially insulation board and application knowledge with an annual capacity of 1,200,000 M3. In 2013, the total turnover volume of BEIPENG exceeds US$83 million dollars with a total staff of 350.

BEIPENG Science and Technology Research is powered by China National Building Materials Academy. Four production lines of XPS extruded polystyrene insulation board introduced from Germany Berstoff in 2009, and then another two production lines of PU foam thermal insulation materials imported from Italy OMS group in 2012.Now BEIPENG is a leader in processing materials used in building, cold storage, airport, railway, waterpower, the ventilation of central air conditioning and etc.

BEIPENG's product range features high-quality insolation board, specialty extruded polystyrene insolation board, polyurethane insulation board, coating, rock wool, polymer mortar, anchor nail, fiberglass and etc. Total solutions from BEIPENG replace older technologies CFC agent, opening unforeseen innovation possibilities for customers.

We hereby meet the highest quality requirements and maximize the advantages of technical progress, social and environmental requirements.

- Q:What is the difference between an extruded board and an XPS extruded board?

- What is the form of this, and you want to be on the scene to be helmet helmet helmet gnome insects rhinoceros kitery to be set. But single, double row scaffolding with a high degree of single-row scaffolding should not exceed 24M, double row scaffolding erection height can not exceed 50 meters, more than 50 meters high double scaffolding should be double pipe, sub-unloading, sub-erection and other measures The "Technical Specification for Safety of Fastener Steel Scaffolding" JGJ130-2011

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Extruded polystyrene board with XPS insulation board is no different, because it is the same thing two kinds of name. Extrusion polystyrene board full name is extruded polystyrene foam board, referred to as extruded plate, also known as XPS board, extruded polystyrene board. Extrusion polystyrene board use: 1 & gt; widely used in wall insulation, flat concrete roof and steel roof insulation; 2 & gt; for low temperature storage ground, parking platform, airport runway, highway and other areas of moisture insulation. Extruded plate is polystyrene resin supplemented by polymer in the heating and mixing at the same time, into the catalyst, and then extruded out of continuous closed-cell foam foam foam, the internal independent of the closed bubble structure, It is a kind of environment-friendly insulation material with high compression resistance, low moisture absorption, moisture-proof, airtight, light weight, corrosion resistance, super-aging resistance (almost no aging for long-term use) and low thermal conductivity. Extruded board is widely used in dry wall insulation, flat concrete roof and roof insulation of steel roof, low temperature storage floor, low temperature floor radiant heating heating pipe, parking platform, airport runway, highway and other areas of moisture insulation, Frost heave, is the construction industry inexpensive, excellent quality of the insulation, moisture-proof material.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- The bar spacing is called 'step distance', 1.2 ~ 1..1.8m, no minimum spacing, maximum 1.8m. Pole spacing 1..1..1.55m, no minimum spacing, maximum 1.55m. See JGJ130 Haifa Fenzhuang Curcuma Gufeng Koufukai -2011 "Construction Construction Fastener Steel Scaffolding Safety Technical Specification" 'Structural Requirements'.

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- In when Edison in the study of incandescent bulbs, in the white hot filament inserted between a metal sheet

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Extrusion insulation board b1 and b2 grade fire resistance distinction is as follows: b1 level from the fire choking level, that is, after leaving the fire automatically extinguished, or 10 seconds off. B2 level for the slow combustion level, that is, after the fire will not be larger, and the drop will not ignite the filter paper;

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Flexible ducts for rigid piping and ducts for gas pipelines for drainage pipes

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BP Extruded Polystyrene Sheet CO2 Foam Board (XPS)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 64 m³

- Supply Capability:

- 30000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords