NU218 Cylindrical roller Bearings mill roll bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Cylindrical roller bearings:

Cylindrical roller bearings belong to separable bearings, whose inner and outer rings are linearly contacted with rollers. They have small friction coefficient, bigger capacity of bearing radial load and are applicable to both bearing heavy load and impact load and high-speed rotation. Cylindrical roller bearings have the advantages of compact structure, strong stiffness, big bearing capacity, small deformation after loaded etc.

CNBM has already successfully developed split cylindrical roller bearings which can be freely installed at any time and any place, to meet the demand of driving and conveying rollway bearings at cooling area of continuous casting. CNBM also can provide special cylindrical roller bearings according to requirement of customers.

Product Application:

- Iron and steel metallurgical industry

- Medium and large motor

- Generator

- Combustion engines

- Machine tool spindle

- Speed reducer

- Loading and unloading machinery and all kinds of industrial machinery

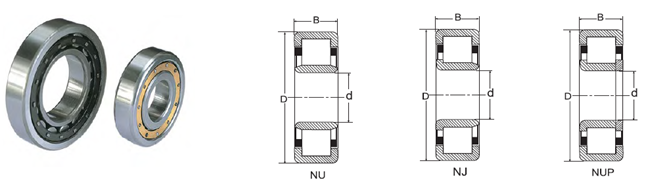

Single row cylindrical roller bearings

- NU, N single row cylindrical roller beaings

NU type and N type allows axis relative the cage within the scope of certain to do axial movement, it would adapt for thermal expansion or installation error caused by the shaft and housing relative position changes, they suit to use for free end bearing. Because they can not limit shaft and the shell axial displacement, and can only bear the radial load.

- NJ, NF single row cylindrical roller bearings

Both NJ and NF can bearing single direction axial load in a certain extent.

- NUP single row cylindrical roller bearings

NUP type bearings with double outer rid, single inner rid and loose rid, this design is possible to limit the axial displacement of the shaft or the housing in double direction within the scope of the axial clearance. in addition they mainly used to bear radial load, also can withstand diameter, the axial union load. Therefore this NUP suitable for fixed end bearings.

- NCL…V single row cylindrical roller bearings

No outer rim but with double lock ring without cage cylindrical roller bearing.

The bearing no cage, roller number is more, and size of the same other cylindrical roller bearing is able to withstand the big radial direction load, but its limit rotational speed is low. The bearing inner ring and outer inseparable, cannot install respectively, can limit shaft or housing of the two directions of the axial displacement in bearing axial clearance within the limit.

| Bearing No. | d | D | B(mm) | Weight(kg) | Bearing No. | d | D | B(mm) | Weight(kg) | |||||

| NU202 | 15 | 35 | 11 | 0.047 | ||||||||||

| NU203 | 17 | 40 | 12 | 0.068 | ||||||||||

| NU204 | 20 | 47 | 14 | 0.110 | NU304 | 20 | 52 | 15 | 0.150 | |||||

| NU205 | 25 | 52 | 15 | 0.130 | NU305 | 25 | 62 | 17 | 0.240 | |||||

| NU206 | 30 | 62 | 16 | 0.200 | NU306 | 30 | 72 | 19 | 0.360 | |||||

| NU207 | 35 | 72 | 17 | 0.300 | NU307 | 35 | 80 | 21 | 0.480 | |||||

| NU208 | 40 | 80 | 18 | 0.370 | NU308 | 40 | 90 | 23 | 0.650 | |||||

| NU209 | 45 | 85 | 19 | 0.430 | NU309 | 45 | 100 | 25 | 0.900 | |||||

| NU210 | 50 | 90 | 20 | 0.480 | NU310 | 50 | 110 | 27 | 1.150 | |||||

| NU211 | 55 | 100 | 21 | 0.660 | NU311 | 55 | 120 | 29 | 1.450 | |||||

| NU212 | 60 | 110 | 22 | 0.810 | NU312 | 60 | 130 | 31 | 1.800 | |||||

| NU213 | 65 | 120 | 23 | 1.050 | NU313 | 65 | 140 | 33 | 2.250 | |||||

| NU214 | 70 | 125 | 24 | 1.150 | NU314 | 70 | 150 | 35 | 2.750 | |||||

| NU215 | 75 | 130 | 25 | 1.250 | NU315 | 75 | 160 | 37 | 3.300 | |||||

| NU216 | 80 | 140 | 26 | 1.500 | NU316 | 80 | 170 | 39 | 3.950 | |||||

| NU217 | 85 | 150 | 28 | 1.900 | NU317 | 85 | 180 | 41 | 4.700 | |||||

| NU218 | 90 | 160 | 30 | 2.350 | NU318 | 90 | 190 | 43 | 5.450 | |||||

| NU219 | 95 | 170 | 32 | 2.850 | NU319 | 95 | 200 | 45 | 6.250 | |||||

| NU220 | 100 | 180 | 34 | 3.450 | ||||||||||

| NU221 | 105 | 190 | 36 | 4.000 | ||||||||||

| NU222 | 110 | 200 | 38 | 4.800 | ||||||||||

- Q:What are the differences between cylindrical roller bearings nu208m and nu208em?

- E means "reinforced", "rolling", "thickening", "change", "change".. Hope to adopt!!

- Q:Full use roller bearings

- INA full capacity roller bearings have many uses and many applications. Germany FAG bearing group global production of rolling bearings and linear products leading enterprises, not only FAG bearings of good quality, but more importantly, FAG industrial services. In order to extend the life of the railway axle box bearing unit, it is decided that the new FAG axle box bearing unit industry service will be added. We will go to Shanghai FAG bearing China general agent to learn about FAG new axle box bearing units, reprocessing industrial services and other industrial services. The FAG industrial services reprocessing service itself includes thorough cleaning of all bearings, as well as inspection of the dimensions and functions of the entire bearing units. Will re adjust the crankcase clearance, re lubrication SKF bearings, any wear parts will be replaced, if requested by the client, bearing data can also be recorded in the database, for future tracking and review.

- Q:How are the twin row cylindrical roller bearings classified?

- Double row cylindrical roller bearings have cylindrical inner bore and conical inner bore (bearing rear code plus K) two structures. This kind of bearing has the advantages of compact structure, large rigidity, large bearing capacity and little deformation after load. It is especially suitable for spindle support of machine tools. The conical inner hole can also play the role of micro adjustment of the clearance, and can simplify the positioning device structure, and is convenient for installation and disassembly.

- Q:Why are cylindrical roller bearings suitable for traveling support?

- Should be the inner ring and the outer ring without the edge of the can do moving support. Cylindrical roller bearings without inner sides of the inner ring or outer ring, whose inner and outer rings can be moved relative to the axial direction, so they can be used as free end bearings.

- Q:What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- NSK bearing type suffix solution of NSK bearing type by the basic code, prefix and post code, the basic code bearing series (including type) diameter and contact angle; pre code specific bearing; post code structure shape, bearing size, material, seal, retainer, clearance, heat tolerance processing, lubrication, change and other technical requirements, in addition to the basic code added after bearing code. NSK bearing model prefix F - deep groove ball bearing with flange outer ring (for D less than 10 mm), for example: F605. HR - high load tapered roller bearings, for example: HR30207J. MF - Flanged, outer race, deep groove ball bearings of specified sizes (D less than 10 mm), MF52. MR - deep groove ball bearings of specific size (for D less than 10 mm), for example: MR31. NSK bearing type rear code (1) internal structure A - internal design and standard different bearings. A - angular contact ball bearings with a contact angle of 30 degrees. A5 - angular contact ball bearings with a contact angle of 25 degrees. B - angular contact ball bearings with a contact angle of 40 degrees. C - angular contact ball bearings with a contact angle of 15 degrees. C - tapered roller bearings with a contact angle of 20 degrees.

- Q:My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- The latter is mainly used as a precision screw shaft for the radial motion and axial runout requirements are very strict, generally used when they are two back-to-back, when pre tightening have strict requirements, general requirements for the radial motion and axial runout should not exceed 5 per thousand mm.

- Q:What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q:How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q:The Russian bearing suffix No. ZST is a cylindrical roller bearing

- The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

- Q:How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 1, radial clearance: non preload, bearing radial load, the radial clearance of G for any angle along the radial direction, in the absence of external load relative to the outer ring inner ring from a radial eccentric limit position, move to the opposite limit position of the radial distance arithmetic mean.2, axial clearance: non preload, bearing can withstand axial load in two directions, the axial internal clearance of G: without external load, a ring relative to the other ring, from an axial limit position toward the average axial distance limit position opposite the.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

NU218 Cylindrical roller Bearings mill roll bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords