NU 203 Ecylindrical roller bearing used mower wheels bearings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Structure: | Cylindrical | Type: | Roller | Brand Name: | OEM |

| Bore Size: | 17 mm | Outside Diameter: | 40 mm | Model Number: | NU 203 E |

| Precision Rating: | P0, P6, P5, P4 | Seals Type: | open type | Number of Row: | Single row/ Double row |

| Place of Origin: | Jiangsu, China (Mainland) | Keyword: | Cylindrical Roller Bearing | Package: | standard export package |

| Cage: | Nylon, Steel, Brass | Material: | Gcr 15 | Precision rating: | P0, P6, P5, P4, P2 |

| Number of row: | Single-row/ Double-row | Certificate: | ISO9001:2000 | OEM: | Acceptable |

| Original: | Made in China |

Cylindrical Roller Bearing Introduction

Rolling body is cylindrical roller bearings - Radial. Cylindrical roller bearings internal structure of the roller was 90 ° perpendicular cross arrangement (which is also cross roller bearings origin of the name), equipped with a gap between the roller cage or spacers can prevent tilting roller or rollers mutual ground between the police, effectively preventing the increase in rotational torque.

Cylindrical roller and raceway for the line contact bearings. Load capacity, the main radial load. Rolling ring wall friction is small, suitable for high-speed rotation. According to ring without ribs, can be divided NU, NJ, NUP, N, NF and other single row cylindrical roller bearings, and NNU, NN and other double row cylindrical roller bearings. The bearing is the inner, outer separable structure.

Inner or outer wall of the cylindrical roller bearings, the inner and outer ring can be relative to the axial movement, so you can use as a free end bearings. On either side of the inner and outer ring of a double-wall, the other side of the ring has a single wall of the cylindrical roller bearings that can withstand a certain degree of axial load direction. General use of steel stamping cage, or copper alloy solid cage. But there are also some use of polyamide forming cage.

Packaging & Delivery

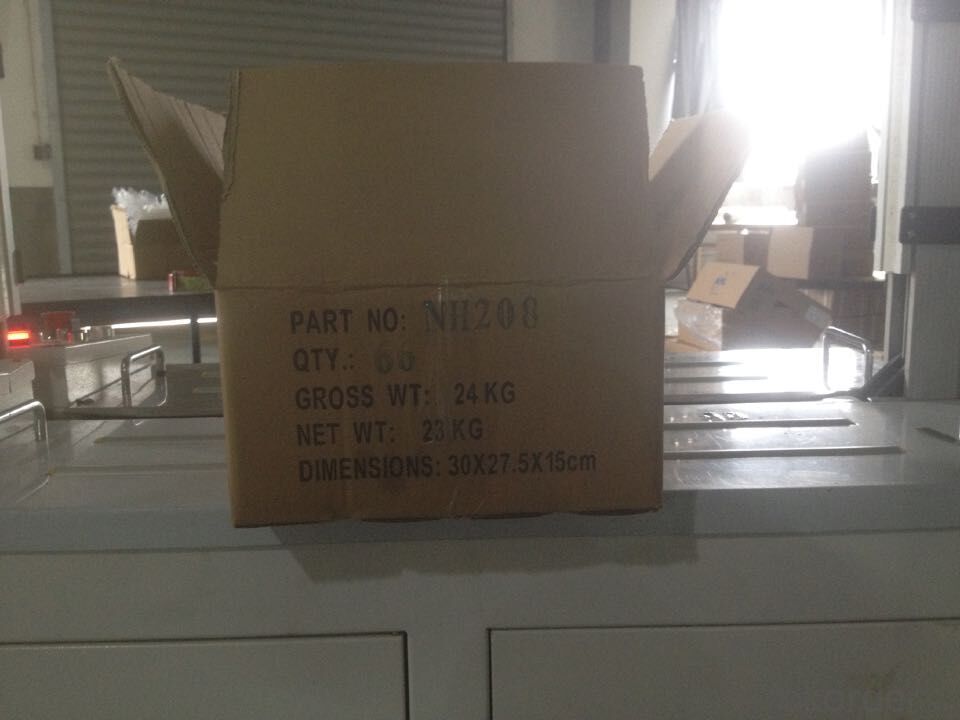

| Packaging Details: | Cylindrical roller bearing (1)Plastic bins +carton box+ wooden case + pallet (2) According to customers' requirements |

| Delivery Detail: | 5-30days according to the quantity and your request |

- Q:For bearing type, no outer ring single row cylindrical roller bearings, bore 40, thickness 21, roller diameter 8, roller length 12

- Specific circumstances need to be further confirmed with your drawings.Reminder: please buy the product specifications and product quality guarantee, so as not to buy fake and inferior bearing products.Handmade, thank you for your adoption, and if you have any questions, please continue to ask.

- Q:Why does cylindrical roller bearings fail abnormally?

- 5, improper reinforcement of uranium bearing seat, so that the bearing capacity of the axle is uneven, the bearing seat is provided with holes, or some fasteners, such as a compression screw, etc., are supported, and the supporting parts are provided with grooves or printing places near the roller track of the cylindrical roller bearings.

- Q:What does "cylindrical roller bearing" ENV mean?

- Cylindrical roller bearings, the basic model suffix ENV meaning:E: enhanced design with improved bearing load capacityN: the outer ring of the bearing is provided with a stopping grooveV: full installed roller (no cage)

- Q:Full use roller bearings

- The service is applied to all axle box bearings, including FAG cylindrical roller bearings, spherical bearings and tapered roller NSK bearings. In addition, FAG industry services also provide support to customers in the rail industry who introduce maintenance management systems. INA bearing agent Chinese by helping clients improve internal maintenance procedures, F IS can enhance the data exchange between various departments, and clearly useless procedures, such as entry in IT system and database in different kinds of data. This reduces the cost of raw material management and speeds up maintenance activities. NSK it is very important for the effective maintenance management to install the bearing units rapidly and effectively in china. At the same time, the F IS offers a range of energy saving bearing heaters. Including the FAG Powertimken series induction heater, to enable customers to reduce the installation time of bearing, NSK bearings so as to shorten the downtime, instead of using the traditional heating method (oil bath heating stove, or board). FAG is a research and development partner and supplier of the world's leading Boeing 787 manufacturer. The quality, reliability and efficiency of Schaeffler's aviation bearings, INA bearings, price fits, and performance in extreme conditions, the INA bearing agent provides support for the international space navigation corporation. FAG's bearing technology is used on almost all modern aircraft.

- Q:What's the difference between imported bearings and imported bearings?

- Domestic bearings used in the cage and rivet and washer, spacer ring, sealing ring, pillar, pin etc. the material is divided into black metal materials (such as low carbon steel, stainless steel etc.), non-ferrous metal materials (such as brass, bronze and Aluminum Alloy etc.) and non metal materials (such as plastics, phenolic textolite three) etc..Imported bearings are basically the same as those made in China. There are copper, steel, alloy and so on.

- Q:Cylindrical roller bearingWhat are cylindrical roller bearings, are they available in Kunshan?

- The utility model is suitable for occasions where the bearing requirement is higher.

- Q:My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- The latter is mainly used as a precision screw shaft for the radial motion and axial runout requirements are very strict, generally used when they are two back-to-back, when pre tightening have strict requirements, general requirements for the radial motion and axial runout should not exceed 5 per thousand mm.

- Q:How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q:For example, NU, NJ, N, RNU, NUP, NF, NO, NN, RN, what do you mean, who can tell me about that hero?

- NU outer ring, double retaining ring, inner ring without edgeNJ outer ring, double retaining ring, inner ring, single edge

- Q:NSK cylindrical roller bearings EW/EM series of differences and characteristics

- E international is called "reinforced type" load, also means to increase rolling bodyW international is called a steel cage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

NU 203 Ecylindrical roller bearing used mower wheels bearings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords