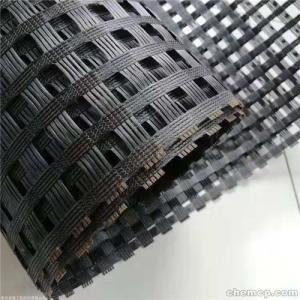

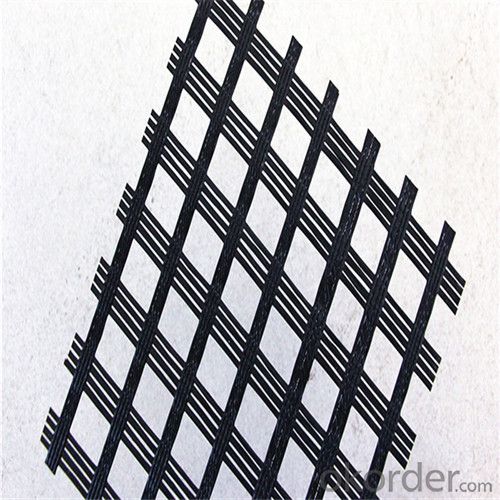

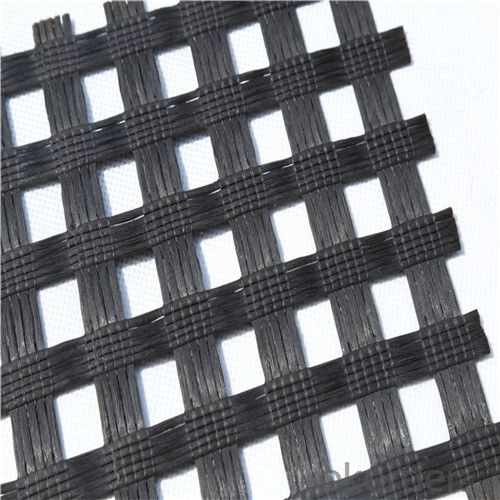

High Strength Polyester Geogrid for Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Polyester Geogrid Description

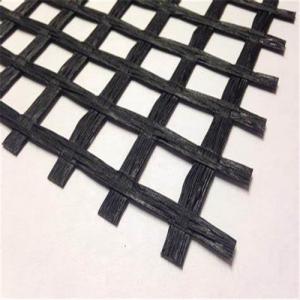

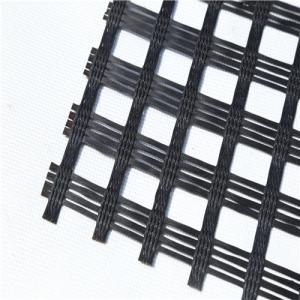

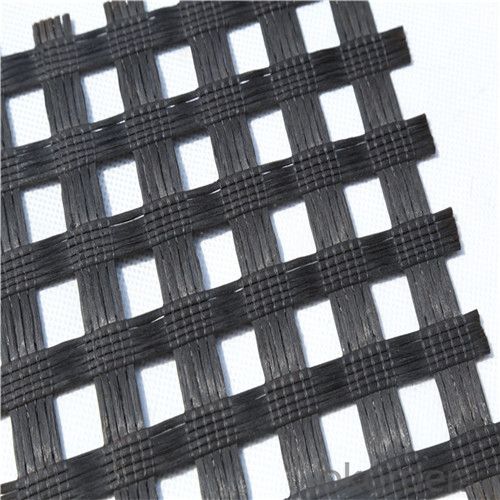

Polyester Geogrid chooses polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending between warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction, then it forms into a mesh size product after coated with high quality oil-soluble PVC.

Polyester Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN, 150-150KN, 200-200KN,

Roll Size: 3.95x100m, as request,

Polyester Geogrid Property

1) High tensile strength

2) Low elongation

3) Anti-erosion, anti-aging

4) Good affinity with base material

5) Light weight, water drainage

Polyester Geogrid Application

1) Roadbed reinforcement in highway, railway and municipal road.

2) Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

3) Roadbed slope reinforcement, retaining wall reinforcement.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing reinforcement and stabilization to the base layer of the pavement. They distribute the load more evenly, preventing localized stress and deformation. This helps to maintain the integrity and structural stability of the pavement, reducing the potential for rutting, cracking, and other forms of distress.

- Q: Geogrid tgsg45-45 what does it mean

- Geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- At the same time has the ability to adapt to the deformation of good, and has good drainage capacity of plane surface, soft multi gap has good friction coefficient can increase soil particle adhesion ability, can prevent the fine particles by preventing particulate loss and eliminate excess water, the surface is soft protection ability good. According to the length of filament is divided into filament non-woven geotextile or short silk non-woven geotextile. They can play a very good filtering, isolation, reinforcement, protection and other functions, is a widely used geosynthetics. The tensile strength of the filament is higher than that of the short filament. Mainly is the high quality polyester staple fiber (fiber based 4-9dtex, length 50-76mm) can also according to the requirements of production of polypropylene, nylon, vinylon fiber or mixed needle nonwoven geotextile. It features 1 isolation of 2 filtered 3 drain 4 reinforcement

- Q: Are geogrids suitable for use in permafrost conditions?

- Geogrids are generally not suitable for use in permafrost conditions due to their potential to cause ground disturbance and accelerate thawing of the frozen soil. Permafrost is a delicate and sensitive environment, and any disturbance to its structure can lead to significant damage and instability. Therefore, alternative solutions specifically designed for permafrost conditions should be considered to ensure long-term stability and environmental protection.

- Q: How do geogrids help in soil reinforcement?

- Geogrids help in soil reinforcement by distributing the load applied to the soil over a wider area, thereby reducing the pressure on the soil and improving its stability. They act as a reinforcement material, providing tensile strength to the soil and preventing it from sliding or shifting. Additionally, geogrids enhance the cohesion between soil particles, increasing the overall strength and preventing the formation of cracks or failures.

- Q: How much investment is needed for the grid cloth on the production site

- You need to spread the production capacity of a loom one day about 1K meters, a width of 1 meters looms, about 4500 a, 2 meters in width of about 12000 a, and other auxiliary facilities, in addition to loom workshop. About 100 thousand.

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are highly effective in reinforcing the soil and providing stability, which is essential for supporting heavy equipment and infrastructure in these facilities. They help to prevent soil erosion, increase load-bearing capacity, and improve overall ground stability, making them a suitable solution for oil and gas facilities.

- Q: Who knows how much the staggered distance of the lap joint is

- The staggered distance of the lap joint shall not be less than 300 mm. The concrete specification (geotextile laid overlapping: when) using geotextile as filter layer, should be laid in place in the bottom and sides of the trench wall, soil and reserve covering the top required fabric, straighten ride close to the lower layer, all vertical or horizontal joints should be staggered alternately. The lap length shall not be less than 300MM.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Can geogrids be used in retaining walls for commercial developments?

- Yes, geogrids can be used in retaining walls for commercial developments. Geogrids are commonly used as reinforcement materials in retaining walls to increase their stability and strength. They provide additional support to the structure by preventing soil erosion and sliding, making them suitable for use in commercial developments where a strong and durable retaining wall is necessary.

- Q: In the case of the subgrade with Geogrid

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material

Send your message to us

High Strength Polyester Geogrid for Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords