Non-skid FRP grating aimpact resistance 2015

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

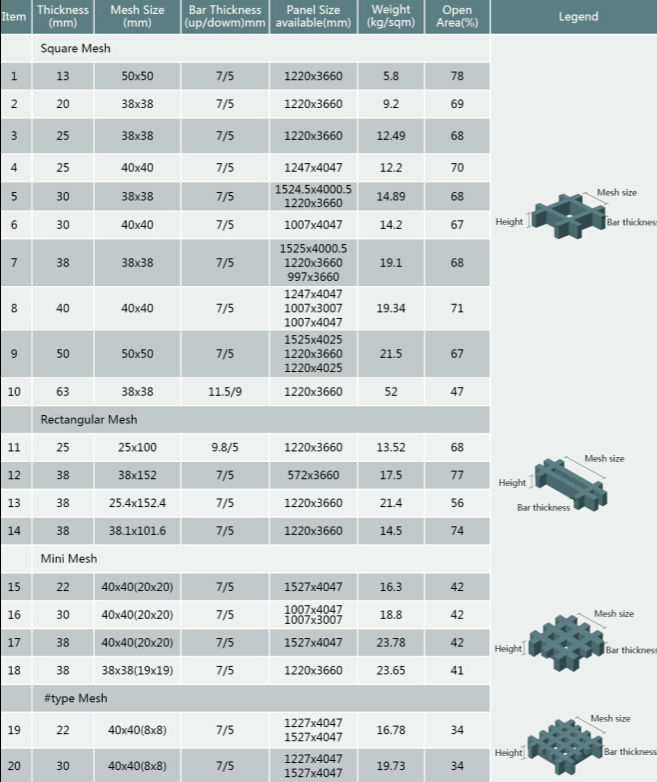

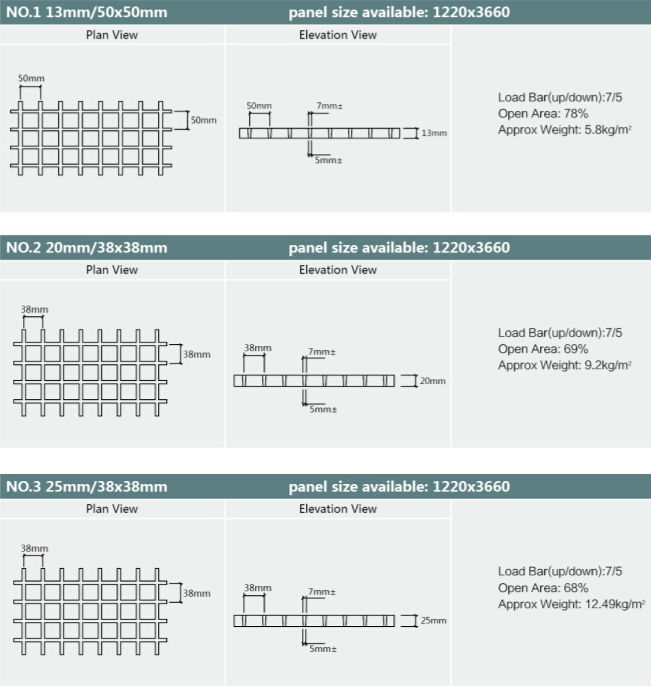

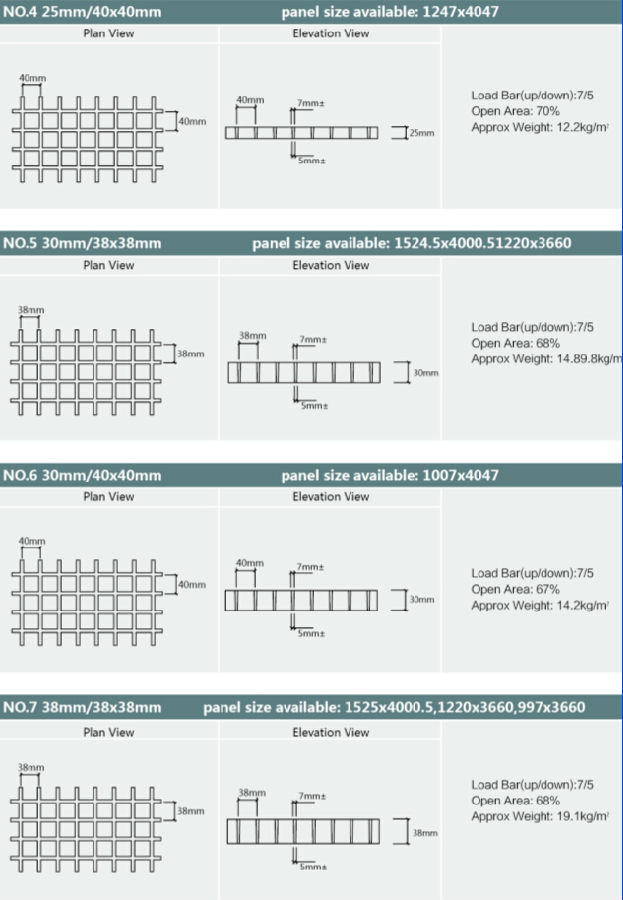

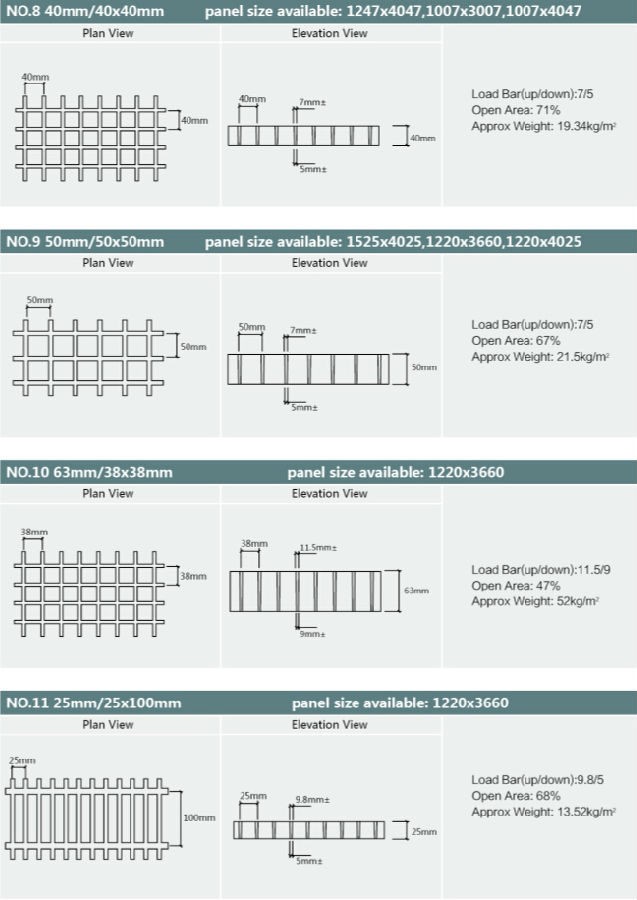

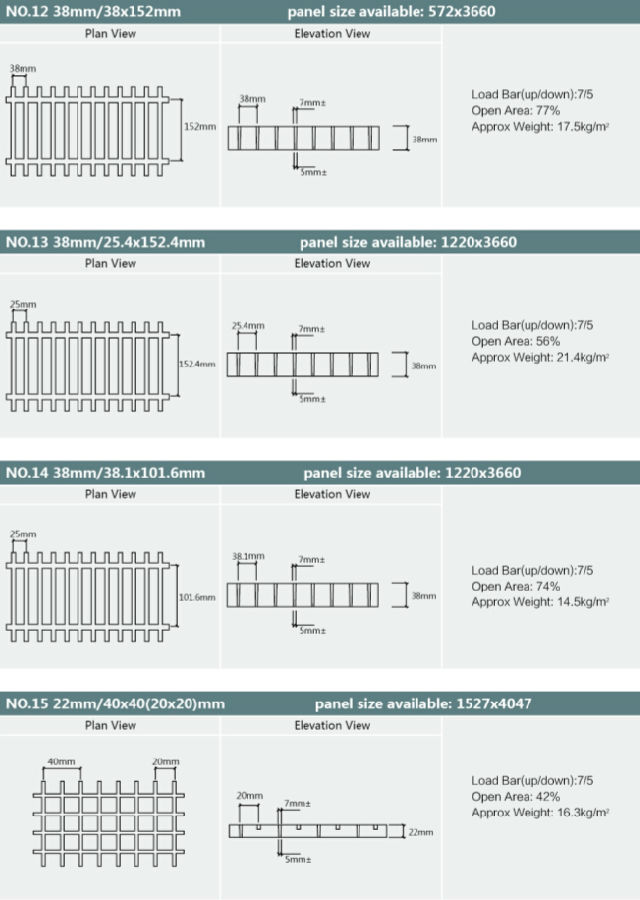

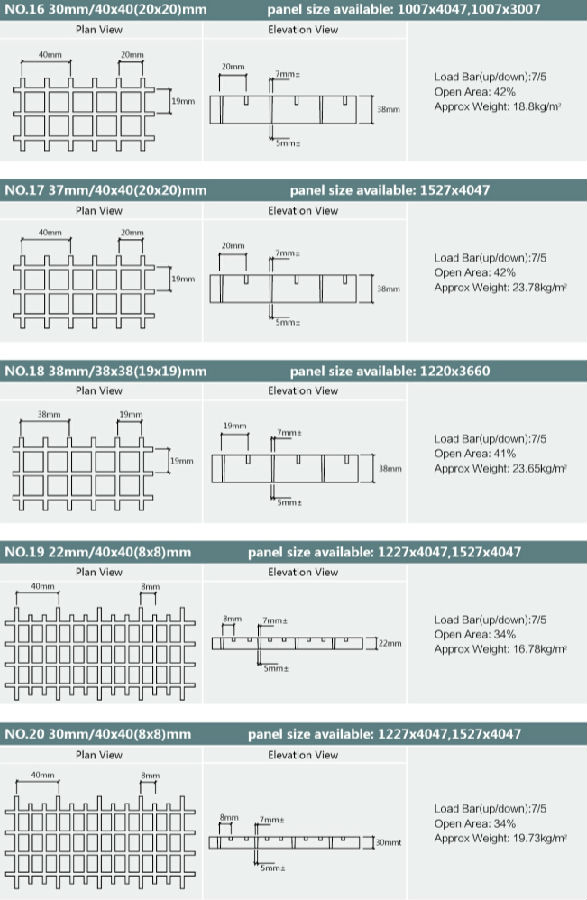

Moded Grating Sizes List:

- Q:Can FRP pultrusion profiles be used in telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications applications. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications infrastructure. Firstly, FRP pultrusion profiles are lightweight yet strong, which makes them ideal for applications such as antenna supports, cable trays, and equipment racks. Their high strength-to-weight ratio allows for easier installation and transportation, while still providing the necessary structural support. Secondly, FRP pultrusion profiles are corrosion resistant, which is a crucial characteristic in telecommunication applications. Telecommunications infrastructure is often exposed to harsh environments, including moisture, chemicals, and extreme temperatures. Unlike traditional materials like steel or wood, FRP does not corrode or degrade in these conditions, ensuring long-term durability and reliability. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is vital in telecommunications applications. They do not conduct electricity, making them safe for use in areas where electrical equipment is installed. This feature helps prevent electrical interference and ensures the integrity of the telecommunication system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in designing telecommunication infrastructure. This versatility makes FRP pultrusion profiles suitable for a wide range of applications within the telecommunications industry. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes make them a reliable choice for supporting and protecting telecommunication infrastructure.

- Q:Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q:Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of safety barriers. FRP pultrusion profiles offer several advantages over traditional materials like steel or concrete when it comes to safety barrier applications. Firstly, FRP pultrusion profiles are incredibly strong and durable. They have high tensile strength, which means they can withstand heavy loads and impacts without deforming or breaking. This makes them suitable for withstanding the forces that safety barriers may encounter, such as vehicular collisions or other accidents. Secondly, FRP pultrusion profiles are lightweight. Compared to steel or concrete, FRP is significantly lighter, making it easier to transport, install, and handle during construction. The lightweight nature of FRP also reduces the overall weight of the safety barrier structure, which can be an advantage in terms of ease of installation and cost-effectiveness. Additionally, FRP pultrusion profiles have excellent corrosion resistance. Unlike steel, FRP is not susceptible to rust or corrosion, which can compromise the integrity and safety of the barrier over time. This makes FRP an ideal material for safety barriers that are exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which can be advantageous in certain safety barrier applications. For example, in areas where electrical or magnetic interference is a concern, such as near power lines or sensitive equipment, FRP barriers can provide an extra layer of safety by avoiding any potential electrical or magnetic hazards. Overall, FRP pultrusion profiles offer a reliable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties make them a suitable choice for a wide range of safety barrier applications.

- Q:Are FRP pultrusion profiles resistant to electromagnetic interference?

- FRP pultrusion profiles are known for their resistance to electromagnetic interference (EMI). By using fiberglass reinforced plastic (FRP) in pultrusion profiles, they offer exceptional electrical insulation properties that effectively minimize the impact of electromagnetic interference. Unlike conductive metals, FRP materials possess high dielectric strength and low electrical conductivity. As a result, FRP pultrusion profiles are less vulnerable to EMI and can serve as barriers against electromagnetic waves. Moreover, if necessary, additional layers or coatings can be applied to enhance the EMI shielding effectiveness of FRP materials. In conclusion, for applications where resistance to electromagnetic interference is crucial, FRP pultrusion profiles are a dependable choice.

- Q:Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP pultrusion profiles offer several advantages that make them well-suited for this application. Firstly, FRP pultrusion profiles are highly corrosion-resistant, which is a critical characteristic for chemical reactors that are exposed to harsh chemicals. Unlike traditional materials like steel or concrete, FRP does not corrode or degrade when exposed to a wide range of chemicals, making it a reliable choice for chemical reactor construction. Secondly, FRP pultrusion profiles are lightweight yet strong, providing excellent structural integrity and durability. This allows for the construction of large-scale chemical reactors without adding excessive weight, reducing installation and transportation costs. Furthermore, FRP pultrusion profiles offer design flexibility, allowing for customization to meet specific requirements. They can be easily molded into various shapes and sizes, enabling the construction of complex reactor designs that optimize efficiency and performance. In addition, FRP pultrusion profiles have excellent thermal insulation properties, which can be advantageous in maintaining stable operating temperatures within chemical reactors. This can help improve the overall energy efficiency of the reactor and reduce heat loss. Overall, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors due to their corrosion resistance, lightweight yet strong nature, design flexibility, and thermal insulation properties. These profiles offer a reliable and cost-effective solution for constructing chemical reactors that can withstand the demanding conditions of chemical processing.

- Q:Can FRP pultrusion profiles be used in the construction of modular buildings?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of modular buildings. FRP pultrusion profiles offer several advantages that make them suitable for modular construction. Firstly, FRP pultrusion profiles are lightweight, yet highly durable and strong. This makes them ideal for use in modular buildings where weight reduction is crucial for transportation and assembly. The strength-to-weight ratio of FRP pultrusion profiles is often higher than that of traditional construction materials such as steel or concrete. Secondly, FRP pultrusion profiles are resistant to corrosion, chemicals, and weathering. This is particularly important in modular buildings, which might be exposed to various environmental conditions during transportation and when assembled on-site. The resistance to corrosion also ensures the longevity and durability of the modular building. Additionally, FRP pultrusion profiles can be designed to have excellent thermal insulation properties. This is advantageous in modular buildings where energy efficiency is a priority, as it helps to reduce heating and cooling costs. Moreover, FRP pultrusion profiles can be easily shaped and customized according to the specific requirements of the modular building design. This versatility allows for the creation of complex and intricate structural components, facilitating the modular construction process. Furthermore, FRP pultrusion profiles are non-conductive, which can be beneficial for safety considerations in modular buildings. They do not conduct electricity, making them suitable for applications where electrical insulation is necessary. In summary, FRP pultrusion profiles are a viable option for the construction of modular buildings due to their lightweight, durability, corrosion resistance, thermal insulation properties, versatility, and non-conductive nature. These attributes make FRP pultrusion profiles a reliable and efficient solution for modular construction projects.

- Q:What are the typical applications of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have a wide range of applications due to their unique properties. Some of the typical applications of FRP pultrusion profiles include: 1. Construction and Infrastructure: FRP profiles are used for various structural elements in buildings, bridges, and other infrastructure projects. They are commonly used for beams, columns, decks, and reinforcement due to their high strength-to-weight ratio, corrosion resistance, and durability. 2. Industrial and Chemical Processing: FRP profiles are extensively used in the industrial sector for applications such as platforms, walkways, ladders, and handrails. They offer excellent resistance to chemicals, heat, and corrosion, making them suitable for harsh environments. 3. Electrical and Telecommunication: FRP profiles are utilized for cable trays, ladder racks, and support structures in electrical and telecommunication systems. They provide electrical insulation and are non-conductive, ensuring safety and reliability in these applications. 4. Transportation: FRP profiles find applications in the transportation industry, particularly in the manufacturing of lightweight components for vehicles, including buses, trains, and trucks. They help reduce weight, improve fuel efficiency, and enhance the overall performance of these vehicles. 5. Marine and Offshore: FRP pultrusion profiles are well-suited for marine and offshore applications due to their resistance to saltwater, UV radiation, and harsh environmental conditions. They are used for boat hulls, piers, dock fenders, and other offshore structures. 6. Recreation and Sports: FRP profiles are employed in the production of various recreational equipment such as ladders, slides, playground equipment, and sports accessories. Their high strength, durability, and resistance to weather elements make them ideal for these applications. 7. Water Treatment and Wastewater Management: FRP profiles are widely used in water treatment plants, sewage systems, and wastewater management facilities. They are used for grating, handrails, ladders, and other structural components due to their resistance to chemicals and corrosion. Overall, the versatility, strength, corrosion resistance, and lightweight nature of FRP pultrusion profiles make them suitable for a diverse range of applications in different industries.

- Q:Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q:Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q:Do you have any high temperature resistant resin made of pultruded glass fiber reinforced plastic?

- Process formula of high temperature epoxy resin pultrusion adhesive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-skid FRP grating aimpact resistance 2015

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords