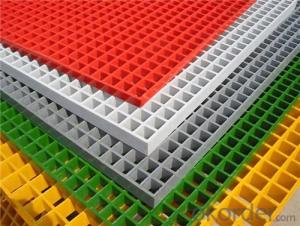

FRP Molded Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of FRP Molded Gratings

The product is a kind of structural plates which uses high-strength fiberglass roving as reinforcing material, thermosetting resin as the base and then is cast and formed on a special metal mold. It provides properties such as: light in weight, high in strength, corrosion resistance, fire resistance, solid and anti-skid. It is widely used in oil industry, power enrineering, sewage treatment, ocean survey as working floor, stair tread, trench cover, and the . It is an ideal loading frame on corrosion circumstances.

Product Performance of FRP Molded Gratings

1. Corrosion-resistance

2. Fire-resistance

3. Light in weight and high in strength

4. Ageing resistance

5. Designable

6. Safe and anti-skid

7. Insulation

Main Application of FRP Molded Gratings

Operation terrace off-shore oil rig Inspection rack

Stair tread Ground floor

Trench cover

Bridge sidewalk foot bridge

Equipment safety fence

Stair landing

Scaffold filling supporting

Decorating grid

Air grid, etc.

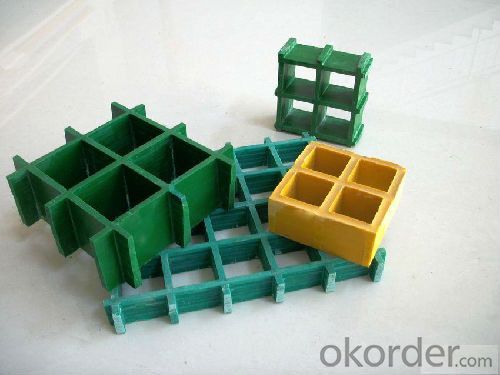

Specification of FRP Molded Gratings

Type | Panel size mm | Lattice size mm | Void ratio | Panel weight Kg |

AS/38.1 x38.1/25.4 | 1220 x 3660 x 25.4 | 38.1*38.1 | 69.9 | 64 |

AS/25.4 x101.6/25.4 | 1220 x 3660 x 25.4 | 25.4 x 101.6 | 63.9 | 73 |

AS/38.1 x38.1/38.1 | 1220 x 3660 x 38.1 | 38.1*38.1 | 70.0 | 92 |

AL/38.1 x38.1/38.1 | 1520 x 3960 x 38.1 | 38.1*38.1 | 70.0 | 114 |

AS/50.8 x50.8/50.8 | 1220 x 3660 x 50.8 | 50.8 x 50.8 | 77.8 | 101 |

AS/38.1 x152.4/38.1 | 1220 x 3660 x 38.1 | 38.1*152.4 | 72.6 | 87 |

AS/38.1 x152.4/38.1 | 579 x 3048 x 38.1 | 38.1 x 152.4 | 74.8 | 34 |

JS/340x40/25 | 1247 x 3087 x 25 | 40 x 40 | 72.3 | 46 |

JS/40 x40/40 | 1247 x 3087 x 40 | 40 x 40 | 72.3 | 73 |

ES/52 x52 /30 | 1000 x 4000 x 30 | 52 x 52 + 19 x 19 | 70.0 | 72 |

ES/52 x52 /50 | 1000 x 4000 x 50 | 52 x 52 + 19 x 19 | 73.3 | 108 |

GS/100 x 100 /25.4 | 117.5 x1480 x25.4 | 100 x 100 | 83.8 | 9 |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

- Q:Do FRP pultrusion profiles require regular maintenance?

- No, FRP pultrusion profiles do not require regular maintenance. They are highly durable and resistant to corrosion, rot, and other environmental factors. This makes them ideal for applications requiring low maintenance and long-term reliability.

- Q:Can FRP pultrusion profiles be used in the production of electrical insulators?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical insulators. FRP pultrusion profiles are known for their excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high-strength and non-conductive nature of FRP materials make them ideal for insulating components in electrical systems, including insulators. FRP pultrusion profiles are made by impregnating continuous fibers, such as fiberglass, carbon fiber, or aramid, with a polymer resin, which is then cured and shaped using the pultrusion process. This results in a durable and lightweight material that offers excellent electrical insulation properties. Electrical insulators are used to prevent the flow of electric current between conductive materials or components. They are essential in electrical systems to maintain safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be designed and manufactured to meet the specific requirements of electrical insulators, including dimensional accuracy, mechanical strength, and electrical insulation performance. Additionally, FRP pultrusion profiles offer several advantages over traditional materials like wood, porcelain, or ceramics. They are corrosion-resistant, have a high strength-to-weight ratio, and can be easily customized to meet the specific needs of electrical insulator applications. FRP pultrusion profiles are also non-conductive, which is a crucial factor for electrical insulation. Overall, FRP pultrusion profiles are highly suitable for the production of electrical insulators due to their excellent electrical insulation properties, durability, lightweight, and customization options.

- Q:Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q:Are FRP pultrusion profiles resistant to caustic solutions?

- FRP pultrusion profiles are known for their resistance to caustic solutions. The combination of reinforcing fibers and the polymer matrix used in FRP pultrusion provides exceptional chemical resistance. Unlike traditional materials like steel or wood, which can be corroded or degraded by strong alkaline substances, FRP pultrusion profiles are highly resistant to chemical attack. This makes them suitable for industries that frequently encounter caustic solutions, such as chemical processing, wastewater treatment, and marine environments. However, it is important to refer to the manufacturer's specifications and guidelines to ensure compatibility between specific caustic solutions and the chosen FRP pultrusion profile.

- Q:Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent corrosion resistance, high strength, and durability. These properties make them suitable for various applications in the water treatment industry. FRP pultrusion profiles can be used in the construction of water treatment tanks, pipes, and other infrastructure. They are resistant to chemicals, including the harsh chemicals often used in water treatment processes. This corrosion resistance ensures a longer lifespan for the equipment and reduces maintenance costs. Additionally, FRP pultrusion profiles have a high strength-to-weight ratio, making them ideal for applications that require lightweight yet strong materials. This allows for easier installation and transportation of water treatment equipment. Furthermore, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes to meet specific project requirements. This allows for customization and optimization of water treatment systems, ensuring efficient and effective water treatment processes. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the water treatment industry. They provide excellent corrosion resistance, high strength, and design flexibility, making them suitable for various applications in water treatment systems.

- Q:Are FRP pultrusion profiles resistant to chemicals used in power plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to the chemicals commonly used in power plants. FRP composites are known for their excellent chemical resistance properties, making them suitable for a wide range of industrial applications including power plants. The specific chemical resistance of FRP pultrusion profiles can vary depending on the resin matrix used and the specific chemicals they are exposed to. However, in most cases, FRP pultrusion profiles are resistant to chemicals such as acids, alkalis, solvents, and corrosive gases commonly found in power plants. It is important to consult with the manufacturer or supplier of FRP pultrusion profiles to ensure that the specific resin matrix and formulation used meets the requirements for chemical resistance in a power plant environment.

- Q:Are FRP pultrusion profiles resistant to fire?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fire. The composition of FRP includes a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which provide excellent fire resistance properties. The resin matrix used in FRP typically has a high flame resistance rating, and the reinforcing fibers do not burn easily. As a result, FRP pultrusion profiles have a high ignition temperature and are inherently self-extinguishing, meaning they will not continue to burn once the flame source is removed. Additionally, FRP pultrusion profiles do not release toxic fumes or smoke when exposed to fire, making them a safer alternative to traditional materials like wood or steel. However, it is important to note that the fire resistance of FRP pultrusion profiles can vary depending on the specific resin formulation and reinforcement material used.

- Q:Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP pultrusion profiles can be used in the construction industry. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability. These profiles can be used in various construction applications such as structural support systems, window and door frames, bridge components, and building facades. They provide a lightweight and cost-effective alternative to traditional construction materials like steel and concrete.

- Q:Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in the production of electrical cabinets. FRP pultrusion profiles have excellent electrical insulating properties, making them a suitable choice for applications involving the production of electrical cabinets. These profiles are non-conductive and can provide insulation and protection against electrical currents, ensuring the safety of the electrical components housed within the cabinet. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them a reliable choice for long-lasting electrical cabinets in various environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords