Midium Duty Type Pallet Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

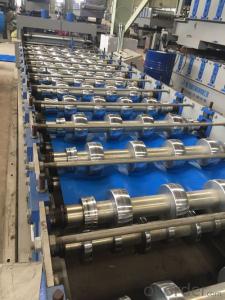

The Medium duty pallet rackging system is used for medium weight goods. It has standard and non standarn type and could be customized design for goods, pallets and etc. The production adopts advanced roll forming technology and guarantee good quality and high precision. Good material ensure long usage life.

Feature:

· use bean and layer structure

· Height could be adjusted

· Big loading weigh

Images:

Specification:

Size | 2000L*600W*2000H |

Loadging | 200-500 KG |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q:What are logistics facilities and equipment?

- Logistics facilities and equipment include logistics, machinery, equipment and logistics infrastructure.

- Q:Storage facilities and equipment is not perfect, what?

- Increase the hardware input to the warehouse.This includes warehouse construction and renovation, purchase of new shelves, pallets, digital automatic identification system and sorting, processing, packaging and other logistics equipment, greatly enhance the level of automation of existing warehouse and logistics operation efficiency, increase the function of logistics services.

- Q:What is the warehouse keeper in the logistics industry?

- The job of the warehouse keeper in the logistics industry is probably:1, according to the provisions of good materials and equipment access library acceptance, billing and distribution work, so that accounts consistent.2, keep abreast of the stock status, ensure the timely supply of materials and equipment, give full play to the efficiency of turnover.3, regular cleaning of the warehouse, keep the warehouse tidy and beautiful, so that materials and equipment classification arrangement, storage neatly, accurate quantity.4, familiar with the corresponding materials, equipment varieties, specifications, models and performance, fill in clearly.5, do a good job of warehouse safety management, check the warehouse fire, anti-theft facilities, plugging loopholes in a timely manner.6 、 complete other work assigned by section chief.

- Q:What are the commonly used automation equipment in warehouse logistics?

- Handheld scanning terminal, etc.. These generally need to work with standardized logistics packaging, such as shelves, materials, boxes, etc..

- Q:The difference between electricity supplier logistics and traditional logistics warehousing management

- (1) a large quantity of traditional logistics warehouse, you can use the forklift to pick goods directly, picking the goods, the efficiency is measured by the number of bins (the original packing box). The picking process is to pick the fruit directly or to seed after picking. An order quantity is large enough to consider how the order is formed.(2) the electricity supplier needs to the scale of victory, a wide variety, but the number of digits, even for a two, when picking an order is clearly not enough to pick the fruit, and consider the need to wave as a unit, while picking fruit while sowing. Therefore, the electricity supplier picking way is RF, picking cart, turnover box.

- Q:What are the problems in e-commerce, logistics and warehousing?

- At present, the application of information technology in logistics enterprises is not only relatively small, but also the application level is low, and the computer applications are limited to office automation and daily transaction processing. According to the China Association of warehousing survey, most of the logistics enterprises in 2002 still do not have the ability to use modern information technology to deal with logistics information. In the information system of logistics enterprises, business functions and system functions of the information system is not perfect, the lack of necessary order management, cargo tracking, warehouse management system and transportation management system of logistics service system, the ability to integrate the logistics information resource has not been formed. Moreover, in foreign countries, logistics enterprises have widely applied bar code technology, and RFID, GPS/GIS and EDI technology are not ideal for the application of Chinese logistics enterprises. In addition, most of the domestic logistics equipment is relatively old, including three-dimensional warehouse, bar code automatic identification system, automatic guided vehicle system, automatic cargo tracking system, including logistics automation facilities, not much. Compared with foreign logistics management automation with electromechanical integration and intelligent characteristics, the gap is great.

- Q:What are the categories of logistics?

- Logistics in the production field runs through the whole process of production. The whole process of production from raw material procurement, it requires the corresponding supply logistics activities, namely the purchase needed for the production of materials; between the production of the process, the logistics process of the raw materials and semi-finished products, namely the so-called production logistics; recovery of surplus material, reusable materials. Is the so-called waste recycling logistics; logistics needs is the disposal of waste.

- Q:The disadvantages of traditional warehousing and the advantages of modern warehousing

- The socialization of warehouse management is not high. Even with the same enterprise, some internal logistics resources can not be shared. As the storage management is backward, the utilization ratio of storage facilities resources is less than 40%, which leads to the low efficiency of logistics

- Q:What role does warehousing play in logistics?

- Warehousing activities, or storage of the basic functions include items of import, inventory, sorting, packaging, distribution and information processing six, among them, the goods out of storage in the database and storage management can be said to be the most basic activities, is the basic of traditional storage, but the management means and management improved; sorting and packaging items, the past is there, but now more widespread, more in-depth, more sophisticated, and even have the goods out of storage and storage management combination, together constitute the basic skills of modern warehouse; the "distribution" as warehousing activities, as one of the basic functions of the warehouse that is because the distribution is not a general sense of the transport, but is a natural extension of the warehouse, warehouse and distribution center for the development of memory requirements, if there is no distribution, warehouse It is still an isolated storage warehouse; as for information processing, is a common phenomenon in modern economic activities, of course, should also be one of the warehousing activities, from information processing, will not become the modern warehouse.

- Q:What are the basic principles of warehousing?

- The "warehouse" also known as the warehouse, store items for buildings and facilities, for housing construction, large containers, caves or specific sites, is to store and protect the function of items; "reservoir" said storage for use, storage, storage, delivery and use of means, when applied to tangible items also for storage. "Warehousing" is the act of using a warehouse to store and store items that are not immediately available. In short, warehousing is the act of storing goods in a particular place.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Midium Duty Type Pallet Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords