Micropore Insulation Board ,Heat Insulation materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | (Mainland) | Brand Name: | |

| Model Number: | 1000 | coating: | alumina foil/glass fiber cloth | Dimension: | 1000*500*10/20/30/40/50 mm |

| Density: | 300kg/m3 |

Packaging & Delivery

| Packaging Details: | wooden box |

| Delivery Detail: | 15 days after receipt of pre-payment |

Specifications

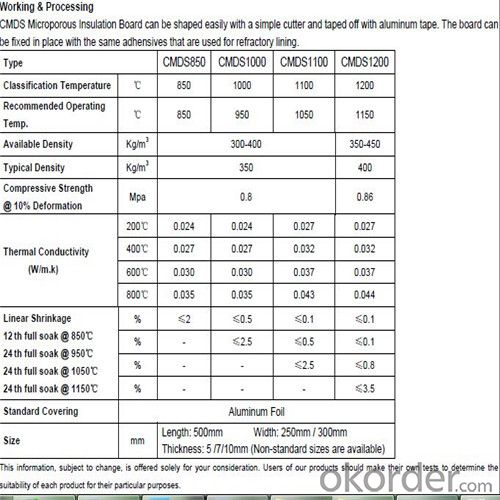

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material

Introduction for Micropore Insulation Board ,Heat Insulation materials

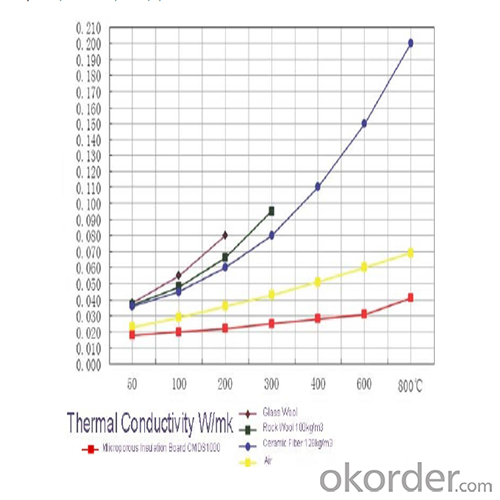

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material is made of nanometer porous high-temperature resistant material and functional material with heat shield function through the combination of nanotechnology and special techniques. It has extremely low thermal conductivity that is just as one forth to one tenth that of ceramic fibre thermal insulation material.

Characteristics:

*High temperature resistance.

*Low thermal conductivity.

*Eco-friendliness and safety.

*Low thermal storage.

*Long service life.

Typical Application:

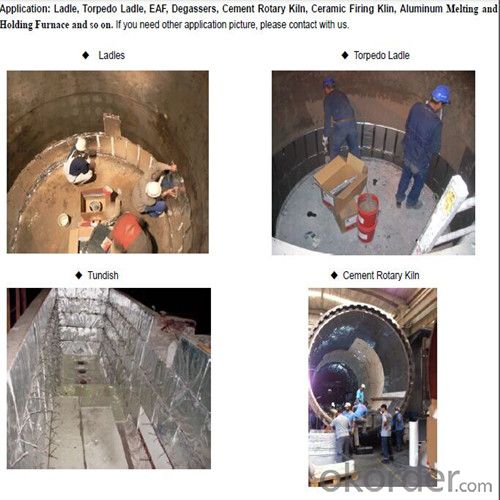

*It is widely used in various industries such as steel, petrochemical

Chemical & Physical Data:

Type | 1000 NATI Micropore Board |

Bulk Density (kg/m3) | 300-350 |

Pressure Strength (MPa) | 0.7 |

Permament Linear Shrinkage %(800℃×6 hour) | 3.5% |

Thermal Conductivity (W/m.K) | 0.020(at 100 ℃) |

0.025(at 200 ℃) | |

0.028(at 400 ℃) | |

0.032(at 600 ℃) | |

0.037(at 800 ℃) |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Can glass fiber textiles be used in printed circuit boards?

- Yes, glass fiber textiles can be used in printed circuit boards (PCBs). Glass fiber textiles, often referred to as glass fiber cloth or fiberglass cloth, have excellent electrical insulation properties and high temperature resistance, making them suitable for use in PCBs. These textiles are commonly used as the base material for the substrate of the PCB, providing mechanical support and stability to the electronic components. The glass fiber textiles used in PCBs are typically impregnated with epoxy resin or other suitable materials to enhance their strength and electrical insulation properties. The impregnated glass fiber cloth is then laminated with copper foil on one or both sides to create the conductive tracks and pads of the PCB. The combination of the glass fiber textile and the copper foil forms a strong and durable substrate that can withstand the demanding requirements of electronic circuits. Glass fiber textiles offer several advantages in PCB applications. They provide excellent dimensional stability, ensuring that the PCB remains flat and unaffected by temperature changes or external forces. The high temperature resistance of glass fiber textiles allows PCBs to be used in applications that generate heat, such as power electronics or high-frequency circuits. Furthermore, glass fiber textiles have low dielectric constant and low dissipation factor, which contribute to the overall electrical performance of the PCB. These properties minimize signal loss and crosstalk, improving the signal integrity and reliability of the circuit. In summary, glass fiber textiles are commonly used in printed circuit boards due to their excellent electrical insulation properties, high temperature resistance, dimensional stability, and low dielectric constant. These textiles provide the necessary mechanical support and electrical performance for a wide range of electronic applications.

- Q:Can glass fiber textiles be used in awnings or canopies?

- Yes, glass fiber textiles can be used in awnings or canopies. Glass fiber textiles, also known as fiberglass textiles, are highly versatile materials that offer various benefits for these applications. They are lightweight, durable, and resistant to weather conditions such as rain, wind, and UV radiation. Glass fiber textiles also have excellent insulation properties, making them effective in creating shade and reducing heat transfer. Additionally, they can be woven into different patterns and textures, allowing for customization and aesthetic appeal. Overall, glass fiber textiles are a suitable choice for awnings or canopies due to their strength, functionality, and versatility.

- Q:Can glass fiber textiles be used in battery separators?

- Glass fiber textiles are capable of being utilized in battery separators. They possess distinct characteristics that render them appropriate for deployment in battery separators. Renowned for their impressive resistance to thermal factors, chemical inactivity, and outstanding electrical insulation attributes, these textiles are ideally suitable for battery separators. Their ability to endure the extreme temperatures and corrosive surroundings within batteries, coupled with their exceptional electrical insulation capabilities, effectively prevent short circuits. Furthermore, glass fiber textiles provide commendable mechanical strength and stability, which are crucial for upholding the structural integrity of battery separators. Ultimately, glass fiber textiles prove to be a dependable and efficient choice as materials for battery separators.

- Q:Can glass fiber textiles be used for geotextiles?

- Yes, glass fiber textiles can be used for geotextiles. Glass fiber has high tensile strength, durability, and resistance to chemicals, making it suitable for various geotechnical applications such as soil stabilization, erosion control, and reinforcement of soil structures.

- Q:How do glass fiber textiles affect water usage?

- Glass fiber textiles do not directly affect water usage as they are not water-intensive materials. Unlike natural fibers like cotton or wool, which require significant amounts of water during cultivation and processing, glass fiber textiles are made from synthetic materials that do not rely on water resources. However, it is important to note that the production of glass fiber textiles still requires energy and resources, including water, for the manufacturing process. Water may be used for cooling or cleaning purposes during production, but the overall water consumption is relatively low compared to other textile materials. Furthermore, glass fiber textiles have certain properties that can indirectly contribute to water conservation. For instance, they are highly durable and resistant to moisture, which means they require less frequent washing or cleaning compared to other fabrics. This reduces the need for water usage in maintaining and caring for these textiles. Overall, while glass fiber textiles themselves do not directly impact water usage, their production and unique properties can have positive implications for water conservation when compared to other textile materials.

- Q:How do glass fiber textiles affect thermal comfort?

- Glass fiber textiles can improve thermal comfort by providing insulation and reducing heat transfer. These textiles have low thermal conductivity, which helps in keeping the body warm in cold conditions and preventing heat from entering during hot weather. Additionally, they have good breathability and moisture-wicking properties, allowing sweat to evaporate and keeping the body dry, enhancing overall comfort.

- Q:Can glass fiber textiles be used in aircraft interiors?

- Yes, glass fiber textiles can be used in aircraft interiors. They are lightweight, durable, and fire-resistant, making them suitable for various applications such as seat covers, curtains, carpets, and wall panels in aircraft cabins. Additionally, glass fiber textiles offer good acoustic insulation properties, enhancing passenger comfort during flights.

- Q:How do glass fiber textiles resist heat transfer?

- Glass fiber textiles resist heat transfer due to the unique properties of the glass fibers themselves. Glass fibers have a low thermal conductivity, which means that they are not good conductors of heat. When heat is applied to the surface of the glass fiber textile, the fibers do not readily transfer the heat to other areas of the textile. This property helps to minimize the transfer of heat from one side of the textile to the other. Additionally, glass fibers have a high melting point, typically around 1500 degrees Celsius. This high melting point allows glass fiber textiles to withstand high temperatures without melting or degrading. Instead of melting, the glass fibers retain their structural integrity, which further contributes to their ability to resist heat transfer. Furthermore, glass fiber textiles can also have an added layer of insulation, such as an aluminum foil or ceramic coating. These coatings create a barrier that reflects heat radiation and prevents it from penetrating the textile. This added insulation enhances the heat resistance of the glass fiber textile, making it even more effective at resisting heat transfer. In conclusion, glass fiber textiles resist heat transfer through their low thermal conductivity, high melting point, and in some cases, added insulation. These properties make glass fiber textiles ideal for applications where heat resistance is required, such as in insulation materials, protective clothing, and fire-resistant barriers.

- Q:Can glass fiber textiles be used in reinforcement of natural yarns?

- Indeed, the reinforcement of natural yarns can be achieved through the utilization of glass fiber textiles. Renowned for their exceptional strength and long-lasting nature, glass fiber textiles serve as an exceptional option for augmenting the characteristics of natural yarns. By integrating glass fiber textiles into the composition of natural yarns, the resulting composite material can exhibit enhanced tensile strength, resistance to tearing, and overall sturdiness. This amalgamation of natural and synthetic fibers proves particularly advantageous in scenarios where a harmonious blend of natural beauty and heightened performance is sought-after, such as the manufacturing of textiles intended for outdoor or high-stress environments.

- Q:Can glass fiber textiles be used for making bags or luggage?

- Yes, glass fiber textiles can be used for making bags or luggage. Glass fiber textiles are lightweight, durable, and have high tensile strength, making them suitable for carrying heavy items. Additionally, they offer good resistance to wear and tear, making them an ideal choice for bags or luggage that need to withstand rough handling and frequent use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Micropore Insulation Board ,Heat Insulation materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords