mica roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

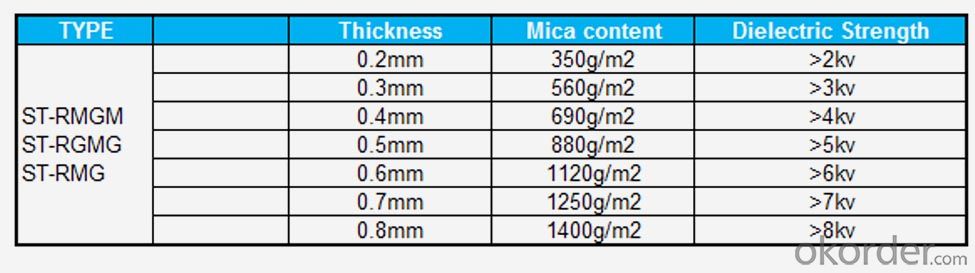

Phologpite mica roll is a result of specially pressed mica product which is made of phologpite mica paper and silicon resin. The thickness ranges

from 0.2mm to 0.8mm, breakdown voltage is above 15KV, tensile strength is above N/15mm and temperature resistance is above 800°C.

◆ ST-RMGM: phlogopite mica paper with glass fiber cloth inside. AVAILABILITY CHARACTERISTIC |

|

- Q:What are the common refractory insulation cotton material?

- I know less about this, I hope the following will help: Fire resistant thermal insulation material mainly refers to inorganic thermal insulation material and compround thermal insulation material. According to the shape can be divided into: Fibrous finishes, slag wool, rock wool, glass wool, aluminum silicate cotton. ceramic fiber, micro pile of diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete etc., foam like bubble glass, volcanic ash glass, foam clay, foaming concrete, paste powder polystyrene particles insulation slurry

- Q:Using what kind of melting aluminium furnace refractories is more appropriate?

- If it's the ordinary, you can use high aluminum refractory brick with general clay, GB/T 3994-2005 clay heat insulation refractory brick. If you need these with good material, there is high alumina thermal insulation refractory brick, GB/T 3995-2006 high aluminum heat insulation refractory brick, models have A13 and material is the alumina, A13 50 u, high insulating brick B5.Intermediate insulating brick B2, etc. Dolomite brick: good hang kiln performance, good erosion resistance, but brick is usually without f - CaO, hydration, and difficult to transport and storage, less used in the production. Magnesia-chrome bricks: good hang kiln, used in calcining zone. The disadvantage is that its thermal shock resistance is poor and plus hexavalent Cr is toxic, the production and use of magnesite chrome bricks in international countries gradually reduce. Now unit using the brick find replacements as soon as possible.

- Q:What is the definition and classification of amorphous fire resistance materials?

- 9.8. brick made of refractory bone material and powder material can be used directly or after adding appropriate liquid formulation Refractory paint. Refractory slinging material 6. Prefabricated cubes, bonding agent or other additives. fire-resistance sparying material compround additives. Refractory pressed into the material, binder. Refractory ramming material 3, The material is a new fire proof material without calcination Heavy aggregate and lightweight aggregate: Inorganic binding agent and organic bond, its fire resistance is not less than 1580. Refractory castables 2 mouldable refractory Classification according to the type of bonding agent: 1. Classification according to refractory aggregate. According to the production and construction method, refractory mud or refractory mire, with a certain proportion of the mixture

- Q:How much is the duration of fire resistance of the porous brick shale?

- This is really a simple question. The temperature should be limited within 1050℃, or it will be scorched. I think 980℃would be acceptable.

- Q:Is it normal for caable fire resistant material to catch on fire?

- Abnormal, preventive measures: 1 take fire preventive measures. Measures taken for fire retardant measures of cable: (1) seal closely with fire resistant materials holes ran by cables through walls, shafts to prevent the cable fire, high temperature gas diffusion and spread when cables are on fire. (2) to wrap the cable with the insulation refractory material, when the cable is surrounded with fire, warpped cable is insulated by the insulation material from fire, so it will not be burned. If the cable itself is on fire, fire will be extinguished thankes to lack of oxygen in warpped cable, to avoid the fire to spread out. 2 to strengthen the cable circuit switch and regular protective check and maintenance, to ensure that the action is reliable. 3 to strengthen the cable operation and monitoring, to avoid the overload of the cable operation. . 4 regularly clean dust on the cable, to prevent cable from catching on fire due to the accumulation of dust. 5 to ensure the construction quality, the quality the cable must be strictly in line with the requirements and standards. 6 cable laying should maintain enough distance form the heat pipe, control cable is no longer than 0.5 meters; power cable is no longer than l meters. Control cable and power cable should be divided into slots, be layered and seperated instead of being overlapped . For the parts that do not meet the requirements, measures must be taken to insulate heat and fire. 7 regularly teat cable , abnormal problem should be handled in a timely manner. 8 install fire alarm so that fire will be discovered on time, and cables will not catch on fire. 9 the cable trench should be kept dry to prevent the cable from being affected with damp, or leading to declined insulating function and short circuit.

- Q:What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q:What are the raw materials of refractory?

- Of course, different types have different raw materials: Magnesite (the electric?smelting: alkaline refractory, magnesia-carbon bricks, alkaline, high-purity) + crystalline flake graphite + phenolic resin + additive (silicon powder, aluminite powder, silicon carbide powder, or high-temperature asphalt,etc.) , acidic refractory: The neutral is not easy to answer. such as. You can check out the classification, such as

- Q:What is the quote of fireproof and soundproof materials used in KTV?

- 1. fire retardant, sound absorbing sheet,eggs,pyramid,sound-absorbing material, piano room, studio, KTV, with glue on the rear, 15 Yuan 2. bar, KTV, fireproof sound insulation cotton, sound-absorbing materials, studio, eggs, drum practice room, sound-absorbing and sound insulation materials, pyramid, 25 Yuan 3. fireproof wood excelsior absorbent, sound absorbing board, wall ceiling decoration materials, materials, theater, KTV, wood color fiberboard, 30 Yuan.

- Q:What are the materials of white firebricks?

- The commonly-used firebricks include alumina bricks, corundum bricks, chamotte bricks, high alumina bricks, diatomite bricks, zircon bricks, lightweight corundum bricks, zirconia bubble bricks and so on ~~~

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

mica roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords