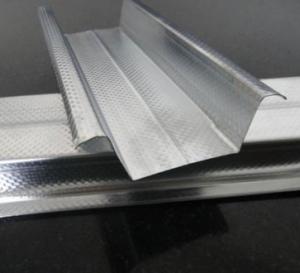

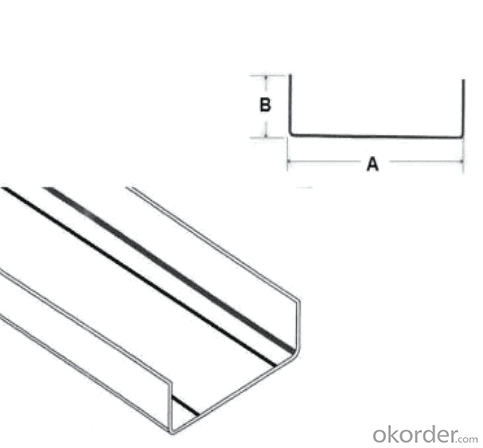

Metal Profile- for Partition and Ceiling System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

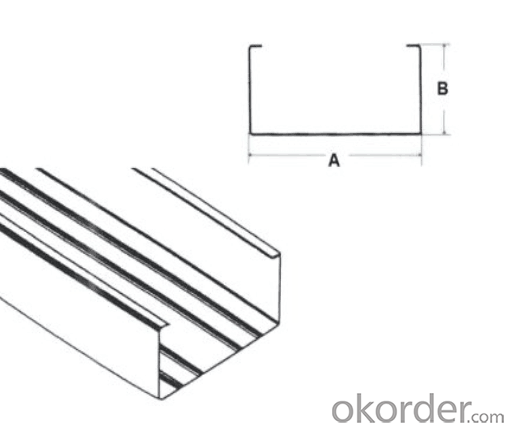

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q:Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Nice, smooth, neat positive

- Q:Light steel keel ceiling and wall construction technology

- Operating conditions 1. Construction of the structure, should be in the cast-in-place concrete floor or prefabricated concrete slab, according to the requirements of the radio, according to embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of large keel arrangement location Steel boom, the general spacing of 900 ~ 1200mm. 2. When the ceiling of the wall of the room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side of more than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed methods should be tested and approved by the approved before the big Area construction.

- Q:Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling to be installed naturally nothing to ceiling accessories - keel. So, the ceiling keel on the ceiling plays a clear support, fixed role. Wood keel ceiling is good or light steel keel ceiling is better? It has a fire and rust anti-aging and other characteristics, but also in the construction of convenient, decorative effect is also very good. Light steel keel is relatively heavy, a long time more or less there will be sagging tendencies. Advantages and Disadvantages of Integrating Ceiling with Wood keel and Light Steel Now the light steel keel generally have been treated with paint, moisture, waterproof performance trustworthy, with a lot of performance. The wood keel light, easy to install and the price is relatively low, but there are some children defect. Wood keel because the main body is wood, it is easy to burn and corrosion, easy to mold in the wet bathroom, which the whole ceiling will cause a great impact. Of course, now a lot of wood keel have done anti-corrosion treatment, but also the surface of the wooden keel is also painted fire protection materials. This greatly improved the role of wood keel. In general, the wood keel ceiling or light steel keel ceiling is good, they have their own advantages, in fact, now with the development of society, integrated ceiling are more light steel keel.

- Q:Home ceiling with green steel skeleton or wooden frame

- Wood keel and light steel keel is the installation of the ceiling when the material, plastic gusset installation need wood keel, aluminum ceiling installation can choose light steel keel and wood keel, but now the market are basically using light steel keel, after all, light steel Keel is metal!

- Q:Light steel keel ceiling material calculation method?

- Plate in square meters, gypsum board for 3 m * 1.2 m / per, ceiling area divided by the area of each gypsum board is the number of gypsum board used, the appropriate put some loss. The main keel per square meter with one meter can be calculated, pay keel per square meter with 3 meters, the boom calculated by two per square meter, the length of the floor height in accordance with the height of the ceiling can be reduced. Suspension fixed parts according to the number of boom configuration, hanging pieces of each square meter 2 calculation, with the number of boom. Hanging by 3-4 per square meter can be. The total number multiplied by the total area can be summed up, plus wealth can be

- Q:Construction schedule of light steel keel ceiling

- Looking for two people, a carpenter, an oiler. Measuring the ball line half a day; punching the boom to half a day; the Lord, the keel half a day; adjust the reinforced keel for half a day; amp; plaster board half a day; caulking treatment for at least two days (generally three times the caulk, the first pass putty must be dry The top layer of paint and lighting installation at least one and a half (according to three times the paint); so calculated at least 7.5 days time, not because of live more, mainly between the process must be Waiting, that is, process control work hours. Do not listen to their blind flick, probably they are not construction workers, I can also finish for you 3 days, but the quality can not guarantee you

- Q:The difference between light steel keel ceiling and macadam ceiling

- The former light weight, you can easily hang a variety of modeling top, which is estimated that no advantage, weight heavier, install trouble, etc.!

- Q:Light steel keel is a flat ceiling or integrated ceiling?

- Light steel keel skeleton is widely used in the decoration of the ceiling can use light steel keel skeleton But in order to facilitate the construction, often the ceiling keel will be used to other materials or the use of other materials and light steel keel construction

- Q:Light steel keel ceiling steps? How to use wood?

- Step 1: the line is the roof with ink cartridges hanging wire and ceiling height of the wall set. ??????? 2: roof bolts with hanging bolts ??????? 3: according to the needs of the height of the ceiling cut off the length of hanging wire hanging wire ??????? 4: nail keel corner ??????? 5: set up the main keel and hanging wire with fastening, need to hang the line to pursue the top of the flatness ??????? 6: laying the vice keel If it is mineral wool board keel size is fixed mostly 50X50 cm if it is gypsum board then it is wide 40X40 cm three meters long set joint keel (gypsum board size is 120X300 unit centimeters) ??????? 7: laying the process of laying the decorative lights and the main light of the fastening plate (decoration workers love to board the board when the light on a very good amount of tight screws)

- Q:Light steel keel ceiling do anti-support angle iron how fixed on the main keel, how fixed on the ceiling surface?

- Ceiling on the anti-supporting material, you can use metal (such as angle iron), you can also use a small piece of wood, but this depends on the supervision requirements, in principle, can not use wood materials, but sometimes as long as the supervision does not speak, With wood materials can be, but the fire paint or to brush.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Profile- for Partition and Ceiling System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products