Low energy consumption Induction furnace for melting iron ore

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard seaworthy treatment |

| Delivery Detail: | 9 months |

Specifications

All confined protective atmosphere

Onload stepless magnetic voltage regulating

Electrode load cell

coaxial conducting

Key Feature:

l State-of-the-art Technology & Facilities

l More than 30 years experience in design & production of bulk material handling system

l More 30% stall are engineers and technical background;

l Patented technology,professional design,accuracy control,safe and reliable operation

l Max. 150t ESR furnace;

Design Management:

![]()

3D • DESIGNFE ANALYSIS • 3-LEVEL REVIEW POLICY • COMPONENT PROCESS ROADMAP & REQUIREMENT

• COMPONENT SINGLE PIECE DRAWING

Process Management:

![]()

Welding & Machining MPP • Welding Process Flow Chart • Welding Procedure • Heat Treatment Procedure

Assembly Procedure • Painting Procedure • Lifting Procedure

Workshop Facilities (Phase 1):

![]()

Welding workshop | Material preparation workshop | Machining workshop | Assembly workshop | |

Dimension | 205m×36m×2 | 156m×26m | 217m×36m×2 | 217m×36m |

Overhead crane | 2×150T/16m | 75T/16m | 2×150T/16m | 2×150T/16m |

Main gate | 16m×12m | 12m×10m | 16m×12m | 16m×12m |

| ||||

After-sales Service:

![]()

Supervision for Installation, Commissioning & Training for Operation & Maintenance

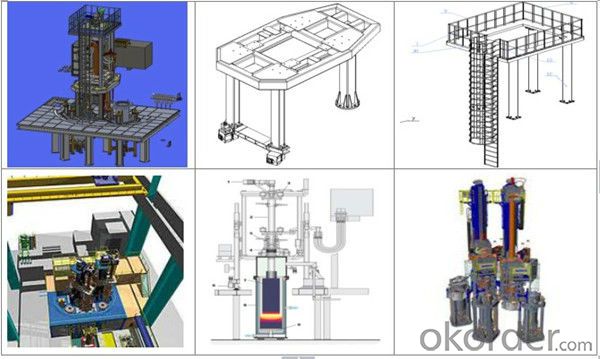

Pictures:

![]()

- Q:What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:What is an industrial furnace pit?

- Later, a chamber kiln with a semi closed or fully enclosed kiln made of refractory bricks can be used as fuel for coal, gas or oil, and electricity can be used as heat source. The workpiece will be heated in the kiln hearth.

- Q:Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q:What are the advantages of a vacuum furnace?

- Energy consumption is lower than salt bath furnace. Modern advanced vacuum industrial furnace heating chamber is made of high quality heat insulation material and wall, which can concentrate electric heating energy into heating chamber with remarkable energy saving effect.

- Q:Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q:What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q:What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low energy consumption Induction furnace for melting iron ore

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords