HDPE Geocell for Retaining Wall and Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

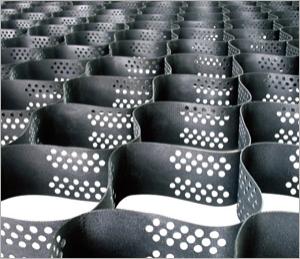

Geocell Description

Geocell is high-molecular polymer, connected by rivets or ultrasonic welded to three-dimensional network structure, unfold it and fill in sand, gravel and clay, etc. when used at construction site.

According to customer’s requirement, cut holes or carve arabesquitic in order to increase its lateral permeable ability, also increase the friction and binding force with the foundation material.

Geocell Specification

Welding distance:330-1000mm

Height:50-250mm

Surface: Textured or Smooth

Color: black,brown,green

Geocell Property:

1) Retractile, foldable when transportation, pulled to net work when construction, fill in the soil, gravel, concrete, atc. Loose materials,

form one structure with strong lateral limitations and high stiffness.

2) Material is light, abrasion resistance, chemical properties stable, resist photooxidation aging, acid and alkali resistant, suitable for different soil and soil conditions, such as desert.

3) Good lateral restrict and prevent slippery, prevent deformation, effectively enhance the bearing capacity of subgrade and dispersed

loads function.

4) The geocell height and welding distance etc. geometric dimensions are all changeable in order to meet the requirement of different projects.

5) Capable and easily be expanded or contracted, small size for transportation, easy for connect and construction speed is fast.

Geocell Application

1) Used for the stability of railway road.

2) To stabilize the desert highway road.

3) Used in the governance of shallow water channel.

4) Used for the foundation reinforcement of retaining wall, wharf, levee.

5) For the management of desert, beaches and river banks

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q:Can geocells be used in railway embankment construction?

- Yes, geocells can be used in railway embankment construction. They are commonly used to provide soil stabilization, erosion control, and improved load distribution in embankments. Geocells help to reinforce the soil and prevent slope failures, making them an effective solution for railway embankment construction.

- Q:Are geocells suitable for use in bridge abutment construction?

- Yes, geocells are suitable for use in bridge abutment construction. Geocells provide an effective solution for soil stabilization and erosion control, which are crucial aspects of bridge abutment construction. They offer high load-bearing capacity, excellent soil confinement, and are easy to install. Additionally, geocells can reduce construction costs and improve the long-term performance of bridge abutments by preventing soil settlement and erosion.

- Q:Can geocells be used for pipeline backfill?

- Yes, geocells can be used for pipeline backfill. Geocells are versatile and effective in providing support and stability to the soil. They can be filled with various materials, such as sand or soil, which helps in creating a strong and stable backfill around the pipeline. Geocells also distribute the load evenly, reducing the chances of settlement or damage to the pipeline.

- Q:Are geocells suitable for use in landfill applications?

- Yes, geocells are suitable for use in landfill applications. Geocells provide stabilization and reinforcement to the landfill liner system, preventing erosion, improving load distribution, and reducing the overall environmental impact of the landfill. Additionally, geocells offer cost-effective solutions and increased lifespan to landfill infrastructure.

- Q:Can geocells be used for sound barrier walls?

- Yes, geocells can be used for sound barrier walls. Geocells provide a stable and flexible structure that can effectively reduce sound transmission. By filling the cells with compacted soil or other materials, geocells can create a strong and durable sound barrier wall.

- Q:How do geocells improve the performance of helipads?

- Geocells improve the performance of helipads by providing a stable and load-bearing surface. They help distribute the weight of the helicopter evenly, preventing the formation of ruts and ensuring better overall performance, safety, and durability of the helipad.

- Q:What are the advantages of using geocells?

- There are several advantages of using geocells. Firstly, geocells provide excellent ground stabilization, improving the load-bearing capacity of soil. This is particularly useful in construction projects where weak or soft soil conditions exist. Secondly, geocells are easy to install and require minimal maintenance, reducing project costs and time. Thirdly, geocells can be filled with a variety of materials such as soil, sand, or gravel, making them versatile for different applications like erosion control, slope protection, and retaining walls. Finally, geocells promote environmental sustainability by reducing the need for excessive excavation and minimizing soil erosion, ultimately protecting the natural ecosystem.

- Q:Can geocells be used in military applications?

- Yes, geocells can be used in military applications. Geocells are versatile geosynthetic products that provide soil stabilization, erosion control, and load support, making them suitable for various military engineering projects. They can be used to create temporary roads, landing strips, and helipads in remote or challenging terrains. Additionally, geocells can be deployed for constructing protective barriers, fortifications, and perimeter walls. The lightweight and easy-to-install nature of geocells make them valuable tools for military operations and infrastructure development.

- Q:Can geocells be used in slope protection projects?

- Yes, geocells can be used in slope protection projects. Geocells are three-dimensional cellular structures made from high-density polyethylene (HDPE) materials that can be filled with sand, soil, or other granular materials. They provide stabilization and reinforcement to slopes by confining and distributing the weight of the fill material, preventing erosion, and reducing the risk of landslides. Geocells are cost-effective, easy to install, and have proven to be effective in slope protection projects.

- Q:Can geocells be used for soil stabilization in residential areas?

- Yes, geocells can be used for soil stabilization in residential areas. Geocells are a cost-effective and efficient solution for reinforcing weak soils, preventing erosion, and stabilizing slopes, which are common challenges in residential areas. They provide structural support and enhance load-bearing capacity, making them suitable for various applications such as driveways, parking lots, and retaining walls. Additionally, geocells can promote vegetation growth and help with stormwater management, making them a viable option for soil stabilization in residential areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geocell for Retaining Wall and Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords