Lightgage steel joist 75stud Environmental Friendly

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Specifications

Used for wall partition

High intensity and toughness

Easy installation

1)Size:

QC 75×45×0.6

QC 75×45×0.7

QC 75×45×0.8

QC 75×45×1.0

2)Features:

(A)light-weight, long lifetime, high durability and rust resistance.

(B)Easy be cut apart, convenience in stallation, environment friendly.

3) Application:

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

3.Image

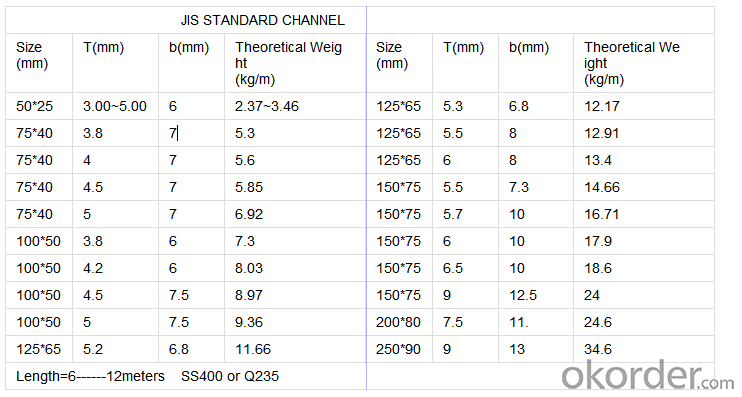

4.Detailed Specification

5.FAQ

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

- Q:Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- 1, gypsum board ceiling does not require the floor, which is fixed on the light steel keel above. In order to prevent the board due to deformation cracking, there are ceiling to do double gypsum board ceiling. 2, if the ceiling has a shape, can be made of wood-based board to shape the profile of tires, and then seal the gypsum board to do latex paint. 3, in the wood grass-roots board on the batch of putty put the latex paint is not good, will crack, because the moisture absorption of wood products, it is recommended to seal the gypsum board cover again to do latex paint.

- Q:140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q:Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- Of course, is the use of supporting the light steel keel (edge keel) better, and the construction (operation) will be more convenient.

- Q:For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling of the keel spacing is too small to easily affect the ceiling of the sound effects and life. Keel skeleton is commonly used in the ceiling of the material, if the early construction of non-standard will seriously affect the aesthetic effect, and may even affect the safety of occupants. The spacing of the keel in the ceiling is very important. The spacing of the keel is different for different ceiling materials.

- Q:Ceiling twenty square meters need light steel keel how many roots

- If the height of the room does not exceed 4 meters, usually: the main keel 1.2 meters, vice keel 4 meters (300MM open file), 1 meter pole, gypsum board 1.05 square (5% loss). Accessories too much here to do not introduce. The above calculation method is limited to flat top, if the shape plus 20% -30%

- Q:Light steel keel ceiling boom and whether the strong electric lines can be common

- Construction regulations are not allowed.

- Q:Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- With the card can be the main bone there is 40 cm in the wall is like to consider the installation of the space

- Q:Light steel keel ceiling one square meter how much money

- Now on the market of light steel keel ceiling is generally 30-40 / square meter, of course, different quality keel ceiling price is not the same, and now we come to understand the light steel keel ceiling installation method!

- Q:Construction schedule of light steel keel ceiling

- Looking for two people, a carpenter, an oiler. Measuring the ball line half a day; punching the boom to half a day; the Lord, the keel half a day; adjust the reinforced keel for half a day; amp; plaster board half a day; caulking treatment for at least two days (generally three times the caulk, the first pass putty must be dry The top layer of paint and lighting installation at least one and a half (according to three times the paint); so calculated at least 7.5 days time, not because of live more, mainly between the process must be Waiting, that is, process control work hours. Do not listen to their blind flick, probably they are not construction workers, I can also finish for you 3 days, but the quality can not guarantee you

- Q:What is a man ceiling, what is not a man ceiling?

- Master ceiling will use a better strength of the special boom and keel. And leave the hole. Not on the use of ordinary keel can be

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightgage steel joist 75stud Environmental Friendly

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords