Lightgage Steel Floor Joist For Suspension Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Lightgage steel joist for ceiling system

Advantages and Features:

1.Light weight,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

1.Material:hot dip galvanized steel

2.Surface treatment: roll coated

3.Application: ceiling grid system

4.Zinc content: 60-140g per sq.m.

Metal steel joist for ceiling suspension keel ,the steel keel was produced by galvanized steel.

functions

1. light weight, high intension, waterproof, earthquake-resistance, dustproof, sound isolation, sound absorption, constant temperature,etc.

2. short time construction peiod and convenient and simple construction.

Lightgage steel joist for ceiling system

3.Image

1.Material:hot dip galvanized steel

2.Surface treatment: roll coated

3.Application: ceiling grid system

4.Zinc content: 60-140g per sq.m.

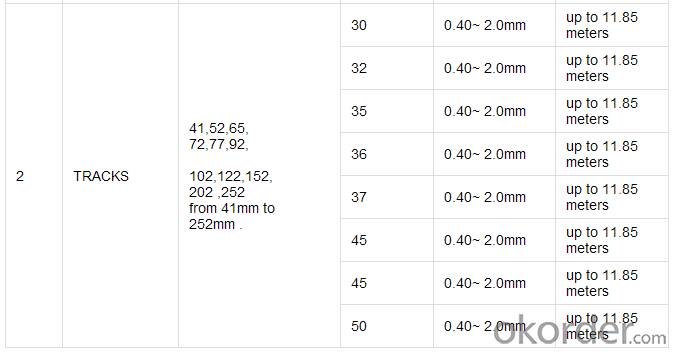

4.Detailed Specification

5.FAQ

Delivery

MOQ: 10 tons, negotiable

Payment term: T/T, 30% deposit.

Port: Tianjin, China.

Delivery time: 15-20 days after received the deposit

- Q:Wood keel expensive or light steel keel expensive?

- The cost of wood keel is higher than that of light steel keel. But the keel is more plastic than the light steel keel strong. So the wood keel to become more commonly used keel material.

- Q:Do steel keel ceiling, need to use white latex?

- As if you can buy a roll of tape. Gypsum board gap filled with putty, with latex to crack the paper tape on the outside. Nails coated with anti-rust paint. Finally, the whole scraping putty. Before the people to do 400 square meters with a variety of woodworking, a total of half a barrel Big bucket

- Q:Light steel keel ceiling price 60 level probably need much money

- A square about a hundred or so package materials

- Q:Light steel keel and wood keel the difference

- Light steel keel is good, will not be damp, will not be deformed, but not easy to do modeling, so there are a lot of home improvement with wood keel, because it is easy to do a variety of shapes, but to brush on the moisture and fire paint. Can be used with white pine

- Q:Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Yes, the more complex shape of light steel can not do, such as s type. K type, heart type and other different types do not come out, the other can do. If you can not do, he may not work

- Q:Light steel keel ceiling budget how to calculate

- According to the net area of the room, the light steel keel and the surface layer, if it is flat sets of a ceiling, if there are high and low sets of hanging ceiling, and can calculate the lamp openings and light boxes, of course, there are other art ceiling Construction requirements and quota related provisions apply to the fixed subhead. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q:Ceiling light steel keel specifications are models which several

- Light steel keel is divided into wall keel (Q) and ceiling keel (D) two categories

- Q:Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- Certainly light steel keel wood keel is not fire waterproof

- Q:Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Will not fall off the light steel keel qualified acceptance criteria is able to hang a person in general home, then people will not fall off the brush on the latex paint can be the color can brush

- Q:Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- If your area of woodworking workers daily wage does not exceed 200 yuan per square can float 8 yuan or so.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightgage Steel Floor Joist For Suspension Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords