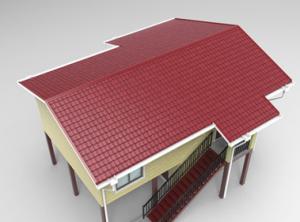

Light Steel Structure House for Papua New Guinea

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

This product belongs to Ligth Steel Frame Structure.

This structure is formed by the dense light steel studs and compound envelop and with all kinds of supprior physical qualities.

Advantages:

1. Flexible combination

2. Easy transportation

3. Fast construction

4. Cost saving

5. Removable & recycle

6. Thermal Insulation

7. Seismic and wind resistance

8. Roof Load-bearing

Packing:

light steel packing: light gauge steel in bulk, decorate panel material in pallet, other fittings all in boxes, loaded into 40' GP and 20' GP on container.

- Q:100 thick roof color steel foam sandwich panels how to calculate the weight

- You calculate 1 square meters wide inside and outside the two thin steel plate added to the foam core weight, the number multiplied by 10, is the bulk density, its unit is ㎏ / m?. Or, weigh each block to remove each area, then multiplied by 10, is the bulk density.

- Q:I want to cut off a lip of about 1/8 by 1/2 to accomodate the upper lip of a tub. I plan to do this with several passes of an abrasive wheel in a circular saw set to 1/8. My question is will I be able to machine the board like this or will I get a crumbling mess? the Hardiback is 1/2.

- Its not like cutting tile. it will not be a clean cut.

- Q:I need to get some garden lawn conservation machinery, which garden machinery need to be used? Or there is no professional website, you can understand this information

- I am specialized in manufacturing, selling garden machinery, if your lawn area is relatively large, it is recommended to use lawn machine, not very big can be used to bear or side hanging brush machine.

- Q:How are geomembranes used in pond liners?

- Geomembranes are used in pond liners to provide a durable and impermeable barrier that prevents water from seeping into the surrounding soil. This helps to maintain the water level in the pond, prevent erosion, and protect the environment from potential contamination.

- Q:How does steel frame formwork handle the placement of openings, such as windows and doors, within the concrete structure?

- A highly versatile and flexible system, steel frame formwork is capable of easily handling the placement of openings, such as windows and doors, in a concrete structure. The system comprises modular panels that are adjustable and customizable to meet the specific dimensions and requirements of the openings. To begin with, precise and accurate positioning of the openings is made possible by steel frame formwork. The modular panels can be easily adjusted and aligned to achieve the desired shape and size of the openings. This guarantees that the windows and doors are located precisely as indicated in the architectural and structural drawings. Furthermore, the steel frame formwork provides ample structural support for the openings. The sturdy and robust steel frames can withstand the pressure and weight of the concrete during the pouring and curing process. As a result, the openings remain stable and undamaged, without any deformation. Moreover, steel frame formwork allows for the straightforward installation of door and window frames. The modular panels can be effortlessly removed to create the necessary space for the frames to be installed. The formwork system also facilitates the accurate placement of anchor bolts or fasteners, ensuring a secure and stable connection between the frames and the concrete structure. Additionally, steel frame formwork permits the integration of various accessories and components required for the openings, such as lintels, sills, and reveals. These can be easily incorporated into the formwork system, resulting in a flawless and professional finish for the openings. In conclusion, steel frame formwork is an efficient and reliable solution for handling the placement of openings in a concrete structure. Its versatility, adjustability, and strength make it suitable for accommodating windows and doors of different sizes and shapes. The precise positioning, structural support, and easy installation provided by steel frame formwork guarantee the seamless integration of the openings into the overall concrete structure.

- Q:2000 watts of laser can cut 2.5mm aluminum-plastic plate (double-sided aluminum), cutting will be reflective of laser damage

- Can not, below a layer of plastic, do not wear

- Q:Can steel props be used for supporting temporary staircases or ramps?

- Yes, steel props can be used for supporting temporary staircases or ramps. Steel props are commonly used in construction to provide temporary support to structures, including temporary staircases or ramps. They are adjustable in height, strong, and durable, making them ideal for supporting such temporary structures.

- Q:While standing on a long board resting on a scaffold, a 72 kg painter paints the side of a house, as shown in the figure below. If the mass of the board is 14 kg, how close to the end can the painter stand without tipping the board over?from the left edge to the first 'leg' of the scaffold is 1.5m. The legs are 2.5 m apart, and the right leg to the right side is 1.5m. So the whole board is 5.5 m long.

- OSHA regulations prevent him from walking outside the supports of the temporary structure, regardless of how well it might otherwise be balanced. It is just a standard safety rule, so you don't need to go through this calculation when your life is at stake.

- Q:Light steel keel gypsum board modeling ceiling

- According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q:Can steel formwork be used in bridge construction projects?

- Yes, steel formwork can be used in bridge construction projects. Steel formwork offers several advantages such as durability, flexibility, and reusability, making it a suitable choice for constructing bridges. It provides the necessary support and structure during the concrete pouring process, ensuring the bridge's strength and stability. Additionally, steel formwork allows for faster construction and can be customized to meet specific design requirements, making it a preferred option for many bridge construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Structure House for Papua New Guinea

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000㎡ m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products