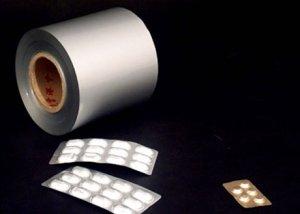

lacquered pharmaceutical foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Application: PTP foil, cold-forming foil, aalu-alu foil

Alloy: 8006/ 8011/ 8079

Temper: H18/O

Thickness& Tolerance: 0.02mm-0.09mm(±6%)

Width& Tolerance: 200mm-1650mm(±1mm)

Lacquer:HSL for PVC

Primer: Primer for printing

Standard: GB/T31988/ASTM-B209/EN546

- Q:How to dye my hair like this?

- call: Alana what's your age minus 9? 8 what's your well-liked holiday? Christmas have you ever offered any new outfits products this week? Yeah, i offered a tank precise from Hollister have you ever lost something down a rest room? No, no longer that i understand of What style is your workstation printer? Dell Is silence truly golden? Yeah, silence at situations is amazingly superb Do you like your hair? no longer trulyblah:( The final compliment you won? you're nonetheless the variety of sweetheart!!!! What shade are your footwear? Maroon could you somewhat be a nun/father or a prostitute? A nun Is your superb buddy rapidly? confident have you ever touched an elephant? No i've got no longer What track is over-performed on the radio? I Kissed a woman by applying Kate Perry Do you like Propel? i like a pair of the flavors have you ever theory somebody died, whilst they actually did no longer? Nope What are you yearning maximum suitable now? no longer somethingI basically ate breakfast and am great duper!!!!! Whats your well-liked candy? White chocolate Reese's Will you supply me a action picture star :) ? effective!!!! Have an somewhat Merry Christmas and revel interior the action picture star I gave you!!!!! :)

- Q:Can I use dyne pen to test the wetting tension in the appearance of aluminum foil? What's the standard?

- What kind of dyne pen imported from America enjoy the highest cost performance? The method can accurately measure the surface tension of the base material, surface wet strength and determine the surface factors of base material. Relative humidity should not exceed the standard since high humidity is easy to aggravate the variability of data.

- Q:A few of my pots and cookie sheets have rusted and I've been too paranoid to eat off themShould I throw them out?

- As for the cookie sheets, just line them with aluminum foil, parchment paper or a silicone fiberglass SILPAT baking mat before you use them to prevent the food from coming in contact with the rustIf they are cast iron cookware, put them into your SELF-CLEANING OVEN cycle at 500+ degreesThe rust will turn to powder and brush right offYou can then re-oil or reseason the pans to prevent them from rusting againBut don't do this with any other type of pan, as plastic handles and other metals will not hold up to that heatBrillo or SOS pads or steel wool will scour the rust off stainless steelIf it's on the outside of the pans, don't worry about itOnly clean the cooking surfacesRust comes from oxidized metalHuman beings are not meant to ingest rust, and rusty metal can cause health issues like tetanus if you step on a rusty nail or cut yourself on a rusty canYou have choices, but high quality cookware with a non-stick coating makes clean-up a breeze and cooking a pleasure! ;-) I suggest you invest in T-Fal or RevereWare and make sure you use non-metal spatulas and utensils to preserve the cooking surface coating.

- Q:Ok so i was supposed to hang out over my friends house on SaturdayI went to pull back the sheets on the guest bdrm and saw a plastic vodka bottle with aluminum foil covering the opening with holes poked in itI made an excuse to leave but its been bothering me all weekNow i was thinking it was a homemade crack pipe.

- Yanni, tough 1 to answerI use drink vodke an never saw a bottle with foil cap as another person saidI have seen them with a plastic insert to slow it comeing out the bottleThis friends a counselor I think you should talk to her, I have heard of cases where drug users left signs lying around in hopes of being caughtBest I can answer, sorryBest Luck Jim

- Q:How to use the bright surface and non-bright surface when having a barbeque.

- The non-bright surface is heat-resistant and the bright surface may release metal toxins yc1962……

- Q:I just got a cheap external enclosure to backup one of my computersIt has no fan but it is made of aluminumI am using Acronis True Image 10 set for weekly incremental backupsShould I just leave the drive on all the time? If not, will Acronis prompt me so that I can turn on the drive at the scheduled time, or will it just fail?

- it would destroy the environment and possibly start a fire, and governments would spend a lot to find out who did itIt would be a big problem, that's for sure, and on a global level and it would affect the price of oil worldwide.

- Q:am building a bridge for my class and need some help in the design of the bridgeHere is a list of the items I get:1.) 100 toothpicks2.) 200 feet of string3.) 25 feet of aluminum foil4.) 10 paper clips5.) 10 rubber bands6.) 1 Roll of Scotch Tape7.) Pair of scissors8.) 12quot; ruler9.) hole punch10.) 10 pieces of construction paper11.) 10 note cardsThe bridge has to span 5 feet and hold approximately 100 pounds on top of the bridgeI only get 30 minutes to build this bridge in class alsoI will have 7 people helping me.Also, what is the best design in case the weight is hanging from the bottom instead?Please help.

- No glue, so the toothpicks are probably uselessRoll the construction paper into tubes about 1 in diameter and tape them Roll the note cards into tubes to be connectors for the paper tubes, let them expand inside the tubes and tack to one tube with tape Fit the tubes together into two identical long tubes over 5 feet long (assuming the paper is big enough) Pull out a sheet of aluminum foil as long as the tubes and roll both tubes side by side snuggly in the foil, taping it firmlyRepeat Shape the tubes into a long arch across the 5 feet against the foundations you better have been given Use the string to add guy wires to stabilize the structure Added complication - mount the paper tubes so the meet in the center, but the ends are spread a few inches, then wrap with foil - if it works, more stable, harder to build.

- Q:Can you freeze turkey stuffing?

- Leftover turkey, stuffing and gravy should be used within one month after freezingUse freezer wrap or freezer containersProper packaging is important to the success of frozen leftoversOtherwise, circulating air in the freezer will create freezer burn – white dried-out patches on the surface of food that make it tough and tastelessUse heavy-duty aluminum foil, freezer paper, or zip-closure freezer bags for best resultsDo not leave air spaceSqueeze excess air from freezer bags and fill rigid freezer containers to the top with dry foodsLeave one-inch headspace in containers with liquid and 1/2-inch in containers with semisolidsDon't forget to label and date packages and use the oldest ones first.

- Q:Band gap in Aluminum Phosphide is 2.5 Electron Volts(1eV1.6e-19 J) What wavelegth of light is emitted?Do you solve this with Braxx's equation?If so, what values would you plug in.

- Vegetables and fruits are high fiberFibers help you increase the speed of your metabolism, which indirectly leads to faster weight loss.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

lacquered pharmaceutical foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords