Jointed Core Black Film Faced Plywood Waterproof

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

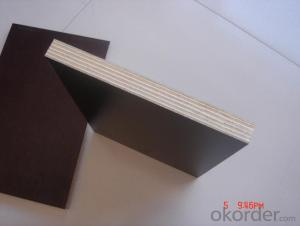

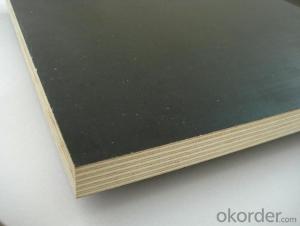

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Product Name | 1250mmx2500mmm or 1220mmx2440mm Construction Film Faced Plywood | |||||

Size | 1220x2440mm, 1250x2500mm, 915x1830mm or as clients requirement | |||||

Thickness | 9~21mm | |||||

Thickness Tolerance | +/-0.3~0.5mm | |||||

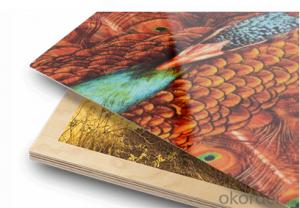

Face/Back | National film (black, brown or red), imported dynea brown film or anti-slip film (black or brown) | |||||

Film Gram | 240g/m2 (black film), 120g/m2 (brown or red film) | |||||

Core | Poplar, hardwood, eucalyptus, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Edge Treatment | Sealed by waterproof paint | |||||

Glue | MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | Film faced plywood is widely used for construction concrete formwork. It has many advantages compared with iron formwork. The advantages are as below: 1. The biggest size of the film faced plywood is 1250x2500mm, which could decrease the number of the joints and increase the working efficiency. 2. Light weight, It's more suitable for high-rise building and bridge construction. 3. It can be used for many times if used and stocked correctly, which can save the cost greatly. 4. It can keep the surface smooth and beautiful when used for pouring, and you don't need to plaster the wall for second time, as it can decorate directly that can decrease the construction period 30%. 5. It will not pollute the surface of the concrete, but iron formwork has the disadvantages of rusty and erosive, ect. 6. It is good for construction in winter that it can be used as template for curved surface. 7. It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling. It can be processed to template with all shapes according to needs. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Certification | ISO9001:2000, CE, CARB | |||||

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q:What are the allowable quantity differences in printed packaging materials?

- Printing, printing, usually three printing on a flat surface of a substrate. Screen printing can not only be printed on a flat surface, but also printed on a surface, and the spherical surface of the substrate is convex. On the other hand, screen printing is not only printed on hard objects, but also can be printed in a soft material without substrate limitations. In addition, screen printing, in addition to direct printing, can also be used according to the needs of indirect printing process, which is to use silk screen printing in gelatin or silica gel version, and then transferred to the substrate. Therefore, we can say screen printing is adaptable and wide range of applications. Strong, rich, textured layer thickness

- Q:What are the materials used in screen printing?

- The range of screen printing applications is very extensive. In addition to water and air (including other liquids and gases), any object can be used as a substrate. Some people have evaluated silk screen printing as saying: "if you want to find the ideal printing method on the earth to achieve the purpose of printing, it is probably screen printing method.".

- Q:What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q:Carton printing process and materials

- Flexo printing and gravure printing of corrugated carton processThese two processes are the first to roll paper printing paper, and then in the automatic corrugated cardboard production line to complete the production of corrugated cardboard. Carton printing quality and molding quality are relatively high, but the investment is relatively large, it is also not suitable for small batch production.In the domestic carton industry, three conventional corrugated carton printing methods are more common, and become the mainstream of corrugated box printing. And the new printing box system, due to equipment, materials, processes, operations and other technical hot spots have not yet been fully mastered, the investment is relatively large, the promotion of the difficulty is still relatively large. But in order to improve the quality of carton enterprises, reduce the total cost of cartons, to maximize profits and increase the competitive advantage in the market, it is imperative to adopt the new printing process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Jointed Core Black Film Faced Plywood Waterproof

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords