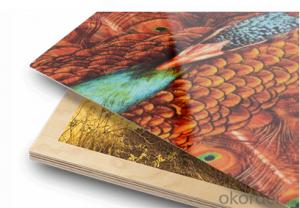

HD Metal Board, HD Aluminium Board, Recommended Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Sublimation Coated Aluminium Sheet

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

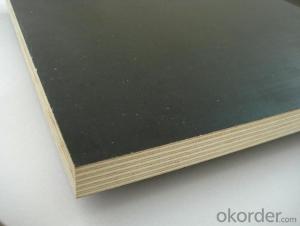

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

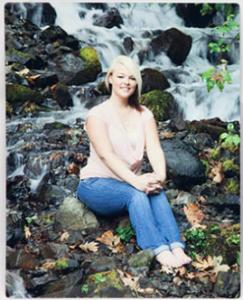

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top

4. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

5. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

6. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

7. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

8. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

9. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

10. Enjoy your personal designed aluminum board!

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

The free samples are available, we're pleased to offer you some for testing.

- Q:How to make the screen print surface smooth?

- Photosensitive adhesive on the printing surface 2-3 times, the back glue once.

- Q:What's the color of the print edition?

- In the subtractive primaries color (yellow, magenta, cyan and black printing). If you use yellow, magenta, cyan, black ink, four colored ink other than the color ink to copy the original color printing process, should not be called "four color printing", but should be called "spot color printing" or "point color printing."".With red, yellow, blue and black pigment (or dye ink) by lithographic printing method of full color copy of the subtractive color mixing principle.

- Q:How can I place the printing rollers in the most convenient place?

- Usually standing, ah, corrugated and blankets on the roll, and outside to get a label, easy to manage. I am a plate factory, and I went to the printing plant is such a release, ha ha, the opportunity to cooperate on the best

- Q:Can you tell me how to make a good print?

- Control version dirty1, the printer will wipe the glass clean; remove the dust on the original manuscript, repair the defect on the original scratch; return the unqualified original, re production. For printing plate exposure caused by insufficient dirt, if dirt is not too serious, can supplement exposure using the diffusion sheet to move the position of the light exposure; can also improve the concentration of the developer, another developer.2, check the developering temperature and development time, and adjust to the corresponding standard; adjust the developer according to the formula given by manufacturer, update the developer; developing layout to fully clean water, the use of high-quality sponge layout; maintenance of automatic developing machine.3, in addition to dirty operation should be careful, apply brush to fill in except dirty liquid, except dirty, in addition to dirty time should be kept in 20, 30 seconds; in addition to dirty liquid use should be covered tightly; layout except dirty treatment, should use water fully flush.

- Q:Why is the screen printing broken?

- There are two kinds of broken screen:1, silk broken2, the film version brokenYou said the screen broken, probably refers to the latter, that is, broken version of film.

- Q:Can I make a screen print?

- With these things, you can start the screen:1. mesh taut stick or nail on the prepared screen frame.2., the photosensitive coating evenly coated in the first step on the preparation of the screen (pay attention to coating evenly, smooth, no light transmission phenomenon)Then blow dry with a hair dryer3. and the back of a film patch ready in the above screen (attached to the outside) and then illuminated with a light source (can be the light of the sun, can also be a fluorescent lamp, also can be the hospital that ultraviolet tube for Deng can also, is a special version of the light (note must be the same network version film tightly, not have the gap between)

- Q:What does the print edition mean?

- Plate (printing), referred to as a printing plate. A carrier for printing pictures on which ink is passed to the substrate.

- Q:How to prevent white leakage before printing?

- The most common trap techniques are Spread and Choke. Spread (commonly known as the "food") refers to the color version of outward expansion in the peripheral white trap overprint block yan. Choke (commonly known as "eat") and the concept of Spread instead, allow external color version inward extension trap. The use of two kinds of trapping techniques, all depending on color and light, the best is contained in the dark. Nothing is impossible in some cases, may be the result of Mixed trap line, Mixed refers to the white line trap is colored with two colors to meet color version produced by mixing color.

- Q:The difference between the 60 and 100 lines of the printing roller

- The principle of letterpress printing is relatively simple. In gravure printing, printing machine inking device to make the ink distribution, then the ink transferred to the printing plate through the roller, due to the graphic part relief is much higher than that of the graphic part, on the plate and therefore, only the ink roller transferred to the printing elements, rather than the graphic part no ink.

- Q:How do I reduce the layout of carton printing?

- When publishing hang article version of paste must and hang banpian base edge alignment. At present, the domestic corrugated carton factory commonly used adhesive tape in hang banpian hang article version of traditional fixed process, this print version in use and after a long time suspension preservation process, due to the relatively hang article version force, often hang article version shift phenomenon, especially in the year second quarter and third in the hot and humid quarter especially. In order to change this phenomenon, part of the corrugated carton enterprise began to use the cold welding technology, will hang banpian hang version with joint material fusion, cooling, the hang article version one-time firmly welding die in banpian hang, ensure the hang article version orientation stability. At the same time, in order to prevent hang banpian near the ends strip tear in force, and generally increase fiber tape for reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HD Metal Board, HD Aluminium Board, Recommended Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords