Hot Rolled unequal Angle Steel for Transmission Towers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

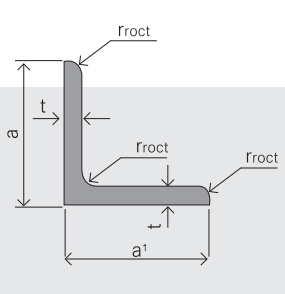

Specifications of Hot Rolled unequal Angle Steel for Transmission Towers

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as transport machinery, ships, industrial furnaces, reaction tower, container frame etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for insteel structrure

1. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q:How do steel angles perform in extreme temperatures?

- Steel angles are renowned for their exceptional performance in extreme temperatures. With their high melting point, they possess the ability to endure both exceedingly high and low temperatures without compromising their structural integrity. When faced with intense heat, steel angles display a remarkable resistance to thermal expansion, thereby preserving their form and strength. Similarly, even in extremely cold conditions, steel angles remain resilient and impervious to brittleness or weakness, ensuring their longevity and dependability. Consequently, steel angles are highly suitable for use in industries such as construction, automotive, and aerospace, where they are frequently subjected to a wide range of temperature variations. Furthermore, steel angles exhibit exceptional fire resistance, further augmenting their effectiveness in extreme temperature scenarios. All in all, when it comes to applications necessitating stability and strength in extreme temperatures, steel angles are the preferred choice.

- Q:What is the angle iron back machine?

- In the structure of angle steel tower, a large number of iron fittings are used. In order to make the connection tight, it is necessary to shovel or clean the angle iron of the iron connecting piece, and the NC angle steel back shovel is just for the purpose of cleaning the angle iron. For more detailed information, you can look at the super CNC website, they are professional manufacturers.

- Q:Are steel angles suitable for window frames?

- Yes, steel angles are suitable for window frames. Steel angles are often used in construction for their strength and durability, making them an ideal choice for supporting the weight of window frames. They provide excellent structural support, ensuring that the window frames remain stable and secure. Additionally, steel angles are resistant to corrosion, which is particularly advantageous for window frames that are exposed to external elements such as rain and humidity. Furthermore, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile option for window frame construction. Overall, steel angles offer numerous benefits that make them a suitable choice for window frames in terms of strength, durability, corrosion resistance, and flexibility.

- Q:Bearing capacity of angle steel and channel steel

- Channel steel is a strip of steel with a cross section. Section steel with groove shape.Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.

- Q:What are the different design considerations for steel angles in industrial buildings?

- Some of the key design considerations for steel angles in industrial buildings include the load-bearing capacity of the angles, the overall structural stability, the desired level of durability and resistance to corrosion, and the aesthetic appearance of the angles. Additionally, factors such as the specific application and function of the angles, the environmental conditions, and the available budget also play a role in determining the design considerations for steel angles in industrial buildings.

- Q:What is the corresponding length of the root weight in the angle standard?

- First, the classification of profiles1. simple section steelThe square - hot rolled steel, cold drawn steel; the round - rolled bar, forging round steel, cold drawn steelThe flat steel wire; 4; 5 - 6 - spring flat steel; equal angle steel, equilateral angle steel and steel triangle;The six angle to the bow; steel; elliptical steel2. complex section steelI-beam -- ordinary I-beam, light I-beamChannel steel -- hot rolled channel (ordinary channel steel, light channel steel), bent channel steelThird, H steel (also known as wide leg I-beam)Rail - heavy rail, light rail, crane rail, other special railSash steelThe steel sheet pile

- Q:What is the typical yield strength of steel angles?

- The yield strength of steel angles can differ depending on the grade and composition of the steel. However, for frequently utilized structural steel angles, the yield strength generally ranges from 36,000 to 50,000 psi (pounds per square inch). This yield strength indicates the level of stress or load that the steel angle can endure before experiencing permanent deformation. It is essential to acknowledge that various steel grades and sizes may possess distinct yield strengths, therefore it is advisable to consult the manufacturer or relevant standards for precise and specific information concerning the yield strength of steel angles.

- Q:Can steel angles be used in mezzanine or raised platform construction?

- Yes, steel angles can be used in mezzanine or raised platform construction. Steel angles are commonly used as structural supports in construction due to their strength and durability. They can be used as framing elements to create the framework of the mezzanine or raised platform. Steel angles provide stability and support to the structure, ensuring its robustness and ability to withstand heavy loads. Additionally, steel angles can be easily welded or bolted together, making them a versatile choice for construction projects.

- Q:Can steel angles be used for conveyor supports?

- Conveyor supports can indeed utilize steel angles. These angles find frequent application in industrial settings, such as conveyor systems, where their structural integrity and durability offer exceptional strength and support. By welding or bolting steel angles together, one can effortlessly construct robust and steadfast conveyor frames. Moreover, their adaptability permits tailoring to meet precise design prerequisites. All in all, steel angles prove themselves as dependable and economical options for supporting conveyors.

- Q:What is the typical tolerance for steel angles?

- The specific application and industry standards determine the typical tolerance for steel angles. Generally, the industry standard allows for a tolerance of ±1/8 inch or ±3 millimeters. This means that the actual dimensions of the angle can differ by up to 1/8 inch or 3 millimeters from the specified dimensions. It is worth noting that these tolerances may differ depending on the grade of steel and the manufacturing process used. Consequently, it is vital to refer to the appropriate industry standards or specifications for the specific project in order to ascertain the precise tolerance requirements for steel angles in that particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled unequal Angle Steel for Transmission Towers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords