Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Stainless steel sheet/stainless steel plate/stainless steel slabs are all widely used in the field of construction field and decoration field, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

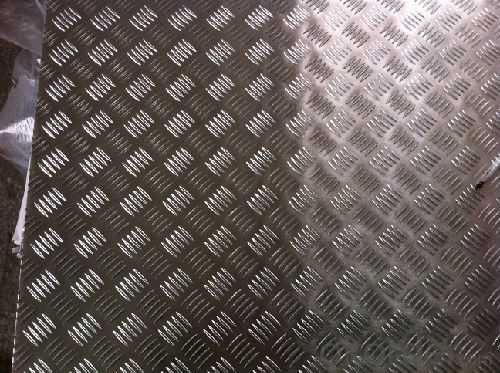

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

500mm*1000mm, 1000mm*2000mm, 1500mm*3000mm,1500mm*6000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q:What are the cost considerations when purchasing stainless steel sheets?

- The cost considerations when purchasing stainless steel sheets include the grade and quality of the stainless steel, the size and thickness of the sheets, any additional finishes or coatings, and the quantity being purchased. Additionally, factors such as transportation and delivery costs, as well as any applicable taxes or import duties, should also be taken into account.

- Q:Can stainless steel sheets be used for electrical enclosures?

- Yes, stainless steel sheets can be used for electrical enclosures. Stainless steel is a highly durable and corrosion-resistant material that provides excellent protection for electrical components. It has high strength and can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. Additionally, stainless steel has good conductivity and can dissipate heat efficiently, which is crucial for maintaining proper temperatures within the enclosure. This makes stainless steel sheets a reliable choice for electrical enclosures, offering long-lasting performance and protection for the enclosed electrical equipment.

- Q:How do you determine the grade of a stainless steel sheet?

- Multiple factors must be taken into account in order to determine the grade of a stainless steel sheet. Firstly, it is necessary to analyze the composition of the stainless steel. Stainless steel is typically composed of a combination of metals, including iron, chromium, nickel, and other elements. The specific percentages of these metals will dictate the grade of the stainless steel. For example, a stainless steel sheet with higher levels of chromium and nickel will generally have a higher grade. The mechanical properties of the stainless steel are also an important consideration. These properties encompass the tensile strength, yield strength, and elongation of the material. Different grades of stainless steel will exhibit varying mechanical properties, which can be assessed using standardized testing methods. Surface finish is another factor that contributes to determining the grade of a stainless steel sheet. The finish can range from rough and dull to smooth and polished. Specific surface finishes may be associated with different grades of stainless steel, and this can be confirmed through visual inspection or the use of specialized equipment. Furthermore, the corrosion resistance of the stainless steel sheet plays a significant role in its grade determination. Stainless steel is renowned for its resistance to corrosion, and higher grades of stainless steel generally offer superior resistance to various corrosive environments. Corrosion testing methods, such as salt spray testing, can aid in evaluating the corrosion resistance of a stainless steel sheet. In conclusion, the grade of a stainless steel sheet can be determined by analyzing its composition, mechanical properties, surface finish, and corrosion resistance. By considering these factors, one can accurately ascertain the grade of a stainless steel sheet and assess its suitability for specific applications.

- Q:304 why is stainless steel magnetic?

- However, due to segregation or improper heat treatment during smelting, there will be a small amount of martensite or ferrite in Austenitic 304 stainless steel. In this way, 304 stainless steel will have a weak magnetic.

- Q:Are stainless steel sheets suitable for elevator handrails?

- Yes, stainless steel sheets are suitable for elevator handrails. Stainless steel is a popular choice for handrails in elevators due to its durability, corrosion resistance, and aesthetic appeal. Elevator handrails are subject to constant use and exposure to various environmental factors, such as moisture and fingerprints. Stainless steel is highly resistant to corrosion, ensuring the longevity and maintenance-free operation of the handrails. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of elevators. Its smooth surface is easy to clean and maintain, making it a hygienic choice for handrails in public spaces. Overall, stainless steel sheets are an excellent material choice for elevator handrails.

- Q:Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is highly resistant to corrosion and can withstand the demands of storing water. It is a common material choice for water tanks due to its durability, hygiene, and longevity.

- Q:What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q:Are stainless steel sheets safe for contact with food?

- Stainless steel sheets? Absolutely safe for food contact! Thanks to its non-reactive and corrosion-resistant characteristics, stainless steel is extensively employed in the food industry. This material won't transfer any harmful chemicals or flavors to your food, making it an ideal option for both food preparation and storage. Moreover, stainless steel is effortlessly cleaned and maintained, reducing the chance of bacterial growth. Nevertheless, it's crucial to mention that not all stainless steel is identical. Therefore, it is advisable to select food-grade stainless steel that adheres to specific standards for food contact.

- Q:How do I bend or form stainless steel sheets?

- To achieve the bending or forming of stainless steel sheets, the following steps can be followed: 1. The first step is to select the appropriate stainless steel grade. Stainless steel is available in various grades, each with its own unique properties. It is important to choose the grade that best fits the requirements of your project, considering factors such as corrosion resistance, strength, and formability. 2. The next step involves using the correct tools. Specific tools like a hydraulic press brake or a metal bending machine are necessary for bending stainless steel sheets. These tools apply force evenly, ensuring precise and consistent bends. It is crucial to use tools that are designed for stainless steel in order to avoid damaging the material. 3. Before bending, it is essential to prepare the stainless steel sheet. This includes ensuring that the sheet is clean and free from any dirt or debris. Additionally, marking the desired bending lines on the sheet using a pencil or tape can serve as a guide throughout the process. 4. The bending angle and radius need to be determined based on the specific requirements of the project. This can be done by using a protractor or a template to accurately measure and mark the desired angles. 5. To prevent any movement or slipping during the bending process, it is important to securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy throughout the bending process. 6. The next step involves applying pressure gradually. It is recommended to start the bending process slowly and gradually increase the pressure. This helps prevent the stainless steel sheet from cracking or warping. Close attention should be paid to the bending process to ensure that the desired shape is achieved without any defects or deformation. 7. If there is a need to create multiple bends or complex shapes, the process can be repeated as necessary. Each bend should be carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. After bending the stainless steel sheet, any residual marks or burrs can be removed using a file or sandpaper. This will give the finished product a smooth and polished appearance. It is important to keep in mind that bending stainless steel sheets can be challenging, particularly for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are uncertain or lack experience in working with stainless steel.

- Q:What are the features of stainless steel plates?

- According to the method of hot and cold rolled two categories, including thickness 0.5.10-885 mm 72938 thin cold plate and 4.5-100 mm thick plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords