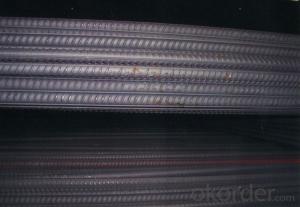

Hot rolled ribbed steel bars (HRB400E~500)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforcing bar (Rebar) refers to the use of reinforced concrete and prestressed concrete with steel, its cross section is round, sometimes for the square with rounded corners. Including light round bar, ribbed steel bar, torsion bar. Reinforced concrete with steel bar is refers to the reinforced concrete reinforcement with straight or plate of strip steel, its appearance is divided into two kinds, light round steel and deformed steel delivery status for the straight bar and wire rod in two. Light round bar is really a small round steel and ordinary low carbon steel wire rod. Deformation is surface ribbed steel bar, usually with 2 longitudinal and cross rib of uniform distribution along the length direction. The appearance of cross rib is spiral, chevron, crescent 3 kinds. With nominal diameter mm number representation. Equals the nominal diameter is equal to the cross section deformation of reinforced light round bar nominal diameter. Reinforcement of nominal diameter is 8-50 mm, recommends to the diameter of 8, 12, 16, 20, 25, 32 and 40 mm. Steel grade: 20 mnsi, 20 mnsi MNV, 25, BS20MnSi. Rebar in concrete main tensile stress. Deformed bars as a result of the action of rib, and concrete have larger bonding ability, thus better able to withstand the role of external force. Steel is widely used in various building structures. Especially large, heavy, light thin wall and high-rise building structure.

Steel processing, steel processing to table and design review, check the material list for errors and omissions, for each steel bar to press

Material list to check whether meet the requirements, after these two checks, then press the material list sent out samples, trial production of qualified rear can batch production, processing and good reinforcement to neatly stacked in order.

Construction such as the need to be reinforced by substitution, must fully understand the design intent and substitution material performance, strictly abide by the current design code of reinforced concrete rules, not to area such as the substitution of low strength of high strength steel reinforcement. Any important parts of a reinforced substitution, shall agree with the consent of party a, design unit, and have a written notice shall be substitution.

(1) the steel surface should be clean, sticky oil, dirt, rust must be cleaned before use, can be combined with cold-drawn rust removal process.

(2) reinforced straightening, usable mechanical or manual straightening. After straightening of steel can not have local small bending, die bending, wavy, its surface scars should not be made of steel decreases by 5%.

(3) the steel bar cutting should be according to the number, diameter, length and quantity, the length is tie-in, first cutting long expected, by cutting short expected to reduce short head, and shorten the steel to save steel.

(4) steel hook or bend:

1) steel hook. There are three kinds of forms, respectively semicircle hook, hook and hook. After bending, bend endothelial contraction, skin

Extension, axis length is constant, bend arc formation, size is greater than the baiting size after bending, bending modifier should be considered.

Reinforced bending diameter of 2.5 d heart, straight part for 3 d. Steel hook increase the length of the theoretical calculation value: counter rotating round hook is 6.25 d, the straight

Hook is 3.5 d, the hook is 4.9 d.

(2) the bending of steel. Middle bending diameter D bend, not less than five times the diameter of the reinforcing steel bar.

(3) the stirrup. Stirrups should be done at the end of the hook, hook form should meet the design requirements. Stirrup adjustment, is the hook to increase the length and bending adjustment

Value or the difference between the two and, according to the amount of stirrup outsourcing size or inside the package size.

(4) reinforced blanking length should be according to the component size, concrete cover thickness, rebar bend modifier and hook to increase the length of the provisions as comprehensive exam

Lv.

A. straight reinforced blanking length = member length - protective layer thickness increase length + hook,

B. turn up steel blanking length = straight length - bend modifier + + inclined curved length increase length of hook,

C. blanking length = stirrup stirrup inner perimeter + modifier + hook to increase length of stirrup.

- Q:Can steel rebars be used in structures with limited construction equipment?

- Yes, steel rebars can be used in structures with limited construction equipment. Steel rebars are durable and versatile construction materials that can be easily handled and installed even with limited equipment. Their flexibility allows for various construction methods, including manual placement and bending, making them suitable for projects with limited machinery. Additionally, steel rebars' strength and resistance to corrosion make them a reliable choice for structures in such conditions.

- Q:Grade 1, grade three, grade two, steel, wire rod, round bar

- Wire is a wire, usually refers to the use of "high speed non-twist wire rod rolling mill, ordinary common low carbon steel, hot-rolled wire torsion free cooling (ZBH4403-88) and the high quality carbon steel, hot-rolled wire rod without torsion cold control (ZBH44002-88).

- Q:Can steel rebars be used in high-rise construction projects?

- Yes, steel rebars can definitely be used in high-rise construction projects. In fact, they are widely used in the construction industry for their strength and durability. Steel rebars are typically used in reinforced concrete structures, including high-rise buildings, to provide tensile strength and reinforce the concrete against cracking or failure. The use of steel rebars in high-rise construction projects helps to ensure the structural integrity and stability of the building. Additionally, steel rebars allow for flexibility in design and can be easily customized to meet the specific requirements of each project. Overall, steel rebars are an essential component in high-rise construction and play a crucial role in ensuring the safety and longevity of these structures.

- Q:What is the effect of carbon content on the strength of steel rebars?

- The strength of steel rebars is significantly affected by their carbon content. Generally, a higher carbon content results in increased strength and hardness in the steel rebars. This occurs because carbon atoms create strong chemical bonds with iron atoms in the steel matrix, resulting in a more rigid and durable material. When carbon is added to the steel, it forms carbides, which are crystalline compounds that enhance the hardness and strength of the steel. The presence of these carbides improves the steel rebars' resistance to deformation, making them suitable for applications that require high strength, such as construction and infrastructure projects. Nevertheless, it is important to consider that there is a limit to how much carbon can be added to the steel rebars to enhance their strength. Excessive carbon content can make the steel brittle and prone to cracking when subjected to stress. This is because excessive carbon atoms can form large clusters of carbides, weakening the overall structure of the steel rebars. Therefore, it is crucial to carefully balance the carbon content in steel rebars to achieve the desired strength and toughness. Depending on the specific application and requirements, different levels of carbon can be utilized to optimize the strength and performance of the steel rebars. In conclusion, the carbon content directly affects the strength of steel rebars. Increasing the carbon content can enhance their strength and hardness, but excessive levels of carbon can result in brittleness. Hence, finding the appropriate balance of carbon content is essential to ensure the optimal strength and performance of steel rebars in various construction applications.

- Q:How do steel rebars help in load distribution within a structure?

- Steel rebars, also known as reinforcing bars, play a crucial role in load distribution within a structure. They are extensively used in concrete structures, such as buildings, bridges, and highways, to enhance their strength and durability. The primary purpose of steel rebars is to provide tensile strength to the concrete. While concrete is excellent in compression, it is relatively weak in tension. Any structure subjected to loads, whether from the weight of the building itself or external forces, will experience both compression and tension forces. By placing steel rebars within the concrete, they act as reinforcement and resist tensile forces. When an external load is applied to the structure, the rebars carry a significant portion of the tension forces generated. This prevents the concrete from cracking or failing under the applied load. Moreover, steel rebars help in distributing the load throughout the structure. When a load is applied to a structure, it creates stress that is distributed across the various components. The presence of rebars allows for a more even distribution of these stresses, reducing the concentration of forces in specific areas. This prevents localized failures and ensures that the load is evenly dispersed across the structure, improving its overall strength and stability. Another important aspect of steel rebars is their ability to bond with concrete. The rough surface of the rebars prevents them from slipping or separating from the concrete, ensuring a strong bond between the two materials. This bond further enhances the load distribution by allowing the rebars to effectively transfer the tensile forces to the surrounding concrete. In summary, steel rebars play a vital role in load distribution within a structure. They provide the necessary tensile strength to resist tension forces, distribute the load evenly across the structure, and bond with the concrete, ensuring a robust and stable construction. Without steel rebars, concrete structures would be significantly weaker and more susceptible to cracking or failure under load.

- Q:How do steel rebars affect the aesthetics of a construction project?

- Steel rebars can impact the aesthetics of a construction project by being visible in areas such as exposed concrete surfaces or through transparent materials like glass. Their presence can create a more industrial or utilitarian look, which may be desirable in certain architectural styles. However, if not properly concealed or incorporated into the design, steel rebars can also be seen as unsightly or disruptive to the overall aesthetic appeal of the project.

- Q:How do steel rebars affect the overall sustainability of a construction project?

- The overall sustainability of a construction project can be significantly influenced by steel rebars. To begin with, steel rebars are commonly employed to reinforce concrete structures, thereby enhancing their strength and durability. This leads to an increase in the longevity of the building, consequently minimizing the necessity for frequent repairs or replacements. As a result, the consumption of materials and energy required for maintenance over the long term is reduced. Additionally, the utilization of steel rebars contributes to the structural integrity of a construction project, enabling the design of lighter and more efficient structures. This, in turn, leads to a reduction in material usage and lower energy consumption during the construction process. Moreover, the use of steel rebars often allows for the construction of slimmer and more aesthetically pleasing structures, which can positively impact the project's environmental footprint. Moreover, steel rebars are recyclable, further enhancing the sustainability of a construction project. At the end of a building's life cycle, it is easy to recover and reuse steel rebars, thereby reducing the demand for new steel production. This not only conserves natural resources but also significantly reduces greenhouse gas emissions associated with the steel manufacturing process. Furthermore, steel rebars can contribute to the overall sustainability of a construction project by improving the building's resilience to natural disasters such as earthquakes or hurricanes. By providing additional strength and flexibility to the structure, steel rebars can help minimize damage and potentially save lives. In conclusion, the usage of steel rebars positively affects the overall sustainability of a construction project by enhancing the structural integrity and durability of buildings, reducing material and energy consumption, promoting recycling and reuse, and improving resilience to natural disasters. Their utilization is a vital component in the creation of more sustainable and environmentally friendly construction practices.

- Q:How do steel rebars affect the seismic performance of a structure?

- Steel rebars significantly improve the seismic performance of a structure by enhancing its strength, ductility, and overall structural stability. Rebars help to distribute and dissipate seismic forces, reducing the risk of structural failure and collapse during an earthquake. By reinforcing concrete elements, rebars increase the structure's resistance to bending, tension, and shear forces, thereby improving its ability to withstand seismic ground motions and maintain its integrity.

- Q:How do steel rebars affect the overall sustainability of a structure?

- Steel rebars have a significant impact on the overall sustainability of a structure. Firstly, the use of steel rebars contributes to the strength and durability of the building, ensuring its longevity and reducing the need for frequent repairs or replacements. This leads to a reduction in the consumption of raw materials and energy required for construction, making the structure more sustainable. Additionally, steel rebars help improve the structural integrity of a building, making it more resistant to natural disasters such as earthquakes and hurricanes. By enhancing the safety and resilience of the structure, steel rebars minimize the potential for damage and loss, which in turn reduces the environmental impact associated with reconstruction and waste generation. Furthermore, steel rebars can be recycled at the end of a building's life cycle. Steel is highly recyclable, and reusing steel rebars significantly reduces the demand for virgin steel production and the associated carbon emissions. Recycling steel also conserves natural resources and reduces landfill waste, making it a more sustainable option than using other materials. Moreover, the use of steel rebars in structures allows for greater design flexibility and adaptability. This means that buildings can be easily modified or repurposed, reducing the need for demolition and reconstruction. The ability to repurpose existing structures reduces waste and energy consumption, contributing to the overall sustainability of the built environment. In summary, steel rebars positively impact the overall sustainability of a structure through their durability, strength, and recyclability. By enhancing the longevity, safety, and adaptability of a building, steel rebars reduce the environmental impact associated with construction, maintenance, and demolition.

- Q:What is the role of steel rebars in the construction of dams and reservoirs?

- Steel rebars play a vital role in the construction of dams and reservoirs as they provide reinforcement and strength to the concrete structures. These rebars are strategically placed throughout the concrete to enhance its tensile strength, allowing it to withstand the immense pressure exerted by the water. By reinforcing the concrete, steel rebars help prevent cracks and structural failures, ensuring the long-term durability and stability of the dam or reservoir.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot rolled ribbed steel bars (HRB400E~500)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords