High Quality Deformed Steel Rebars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000tons/year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Deformed Steel Rebars:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Trade terms | FOB, CFR, CIF | ||

Payment terms | TT payment in advance or Irrevocable LC at sight. | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

Chemical Composition: (Please kindly find our chemistry of our material based on JIS as below for your information)

JISG3112 SD390 | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.22 | 1.38 | 0.4 | 0.014 | 0.022 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

620 | ≥400 | 21 | |||

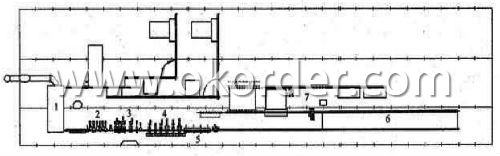

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of High Quality Deformed Steel Rebars:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of High Quality Deformed Steel Rebars:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Price: Keep lower operating costs so as to offer competitive price for our clients

Deformed Steel Rebars according to Korean standard

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q:What is the difference between steel rebars and FRP rebars?

- Steel rebars are traditional reinforcement bars made of steel, while FRP rebars are reinforced polymer bars. The main difference lies in their composition and properties. Steel rebars are strong and durable, but they are prone to corrosion, requiring regular maintenance. On the other hand, FRP rebars are corrosion-resistant, lightweight, and possess high tensile strength. They also offer better thermal and electrical insulation. However, FRP rebars are relatively new in the construction industry and may be more expensive compared to steel rebars.

- Q:What is the difference between hot-rolled and cold-worked steel rebars?

- The main difference between hot-rolled and cold-worked steel rebars lies in the manufacturing process. Hot-rolled steel rebars are produced by heating the steel billets to high temperatures and then passing them through rolling mills to create the desired shape and size. This process results in a rougher surface and higher yield strength compared to cold-worked steel rebars. On the other hand, cold-worked steel rebars are made by subjecting the hot-rolled steel bars to additional processing steps, such as cold drawing or cold rolling. This process enhances the mechanical properties of the steel, including improved tensile strength, dimensional accuracy, and a smoother surface finish. In summary, hot-rolled steel rebars are formed through high-temperature rolling, while cold-worked steel rebars undergo additional steps to further refine their properties, resulting in a smoother surface and improved mechanical strength.

- Q:Are there any specific guidelines for handling and storing steel rebars?

- Yes, there are specific guidelines for handling and storing steel rebars in order to ensure their quality and prevent any damage or accidents. Some of the guidelines include: 1. Handling: When handling steel rebars, it is important to use appropriate lifting equipment, such as cranes or forklifts, to prevent any strain or damage to the rebars. The rebars should be lifted from the center to maintain balance and stability. 2. Inspection: Before storing or using steel rebars, they should be inspected for any defects, such as bends, cracks, or rust. Damaged or defective rebars should be discarded or repaired before use. 3. Storage conditions: Steel rebars should be stored in a dry and well-ventilated area to prevent moisture accumulation and corrosion. They should be stored off the ground on a flat surface, such as wooden pallets or racks, to avoid direct contact with soil or water. Stacking rebars should be done carefully to prevent any deformation or distortion. 4. Separation: Different sizes and types of rebars should be stored separately to avoid mixing or confusion during use. Labeling or color-coding the rebars can help in easy identification and retrieval. 5. Protection: Steel rebars should be protected from exposure to extreme temperatures, sunlight, and chemicals. They can be covered with plastic sheets or tarpaulins to prevent moisture, dust, and debris from settling on them. 6. Transportation: When transporting steel rebars, they should be securely tied or bundled using appropriate strapping or wire. Care should be taken to avoid any impact or vibration during transportation that could cause damage. 7. Training: It is essential to train personnel on proper handling and storage techniques for steel rebars. They should be aware of the hazards associated with improper handling and be equipped with personal protective equipment (PPE) like gloves, safety boots, and helmets. Following these guidelines will help ensure the quality and longevity of steel rebars, minimize the risk of accidents, and maintain a safe working environment.

- Q:What is the role of steel rebars in preventing structural collapse?

- Steel rebars play a crucial role in preventing structural collapse by reinforcing concrete structures. Concrete, although strong in compression, is relatively weak in tension. This is where steel rebars come into play, as they effectively enhance the tensile strength of the concrete. When structural loads are applied to a building or other concrete structure, the rebars distribute the load across a wider area, preventing the concrete from cracking and failing under the stress. By providing a means for the concrete to resist tension and bending forces, steel rebars help maintain the integrity and stability of the structure. In addition to improving tensile strength, rebars also enhance the overall ductility and flexibility of the concrete. This is critical during events such as earthquakes or high winds, where structures need to withstand significant lateral forces. The presence of rebars helps the concrete to absorb and dissipate these forces, reducing the risk of structural failure. Moreover, steel rebars also prevent structural collapse by resisting the effects of corrosion. When embedded in concrete, rebars are protected from moisture and other corrosive elements, ensuring their long-term durability and ability to support the structure. In summary, steel rebars are essential components in preventing structural collapse. They reinforce concrete structures, enhance tensile strength, improve ductility, resist corrosion, and ultimately contribute to the overall safety and stability of buildings and other concrete constructions.

- Q:What is the sign of steel rebar

- Standards are the uniform rules for repeating things and concepts. It is based on the comprehensive achievements of science, technology and practical experience, and is approved by the competent authority and issued in a specific form by consensus by the parties concerned, as a criterion and basis for common compliance.

- Q:How do steel rebars comply with building codes and regulations?

- Steel rebars comply with building codes and regulations by meeting specific requirements outlined in these codes. These requirements include the dimensions, strength, and quality of the rebars, as well as their placement and spacing within the concrete structures. Compliance is ensured through rigorous testing and certification processes, ensuring that the rebars meet the necessary standards for safety and structural integrity in construction projects.

- Q:How do steel rebars help in distributing load in a structure?

- Steel rebars, also known as reinforcement bars, play a crucial role in distributing load in a structure. They are primarily used in reinforced concrete structures to enhance their strength and durability. Rebars are placed strategically within the concrete to counteract the tensile forces that the structure may encounter. Concrete, while strong in compression, is weak in tension. When a load is applied to a structure, such as a building or a bridge, it creates tensile forces that can cause the concrete to crack and fail. By incorporating steel rebars into the concrete, these tensile forces are effectively distributed and transferred to the rebars, preventing the structure from experiencing excessive deflection or collapse. The presence of steel rebars within the concrete creates a composite material that combines the compressive strength of concrete with the high tensile strength of steel. As a result, the structure becomes capable of withstanding a wide range of loads, including dead loads (the weight of the structure itself), live loads (such as occupants or furniture), and environmental loads (like wind or earthquakes). Additionally, rebars also help to control and minimize the propagation of cracks within the concrete. When a crack forms under load, the rebars act as a barrier, preventing the crack from spreading further and compromising the integrity of the structure. This inhibits the development of larger cracks, which could potentially lead to structural failure. Moreover, steel rebars provide stability and reinforcement at critical locations within the structure, such as corners, joints, and areas prone to high stress. By reinforcing these vulnerable areas, the rebars ensure that the load is evenly distributed throughout the structure, reducing the risk of localized failures. In summary, steel rebars are essential in distributing load in a structure by absorbing tensile forces, enhancing the strength of concrete, preventing cracks from propagating, and providing reinforcement at critical locations. They significantly contribute to the overall structural integrity and safety, making them a vital component in construction projects.

- Q:What is the cost of steel rebars compared to other reinforcement materials?

- The cost of steel rebars is generally higher compared to other reinforcement materials such as fiberglass or plastic. However, steel rebars are widely used in construction due to their superior strength and durability, making them a preferred choice despite the higher cost.

- Q:How do steel rebars affect the ductility of reinforced concrete?

- Steel rebars can significantly enhance the ductility of reinforced concrete. The presence of rebars improves the tensile strength of concrete, which is otherwise weak in tension. By reinforcing the concrete with rebars, it becomes more resistant to cracking and can better withstand bending or stretching forces without fracturing. This increased ductility allows reinforced concrete structures to better absorb and distribute applied loads, making them more durable and resilient.

- Q:How are steel rebars used in flat slabs and beams?

- Steel rebars are used in flat slabs and beams to provide reinforcement and increase the structural strength of the concrete. They are placed strategically within the slabs and beams to resist tensile forces and prevent cracking or failure under heavy loads. The rebars act as a framework that enhances the overall durability and load-carrying capacity of the flat slabs and beams, ensuring their stability and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; East Asia; Middle east |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 40%-60% |

| No.of Employees in Trade Department | 21-60 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 850,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

High Quality Deformed Steel Rebars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000tons/year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords