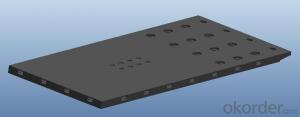

hollow plastic construction formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Hollow Concrete Template:

Standard measure:1830*915*15mm,other size can be customized.

National Patent,Authority Attestation,Quality Assurance.

Wear-resisting,Corrosion resistance.

Nonabsorbent,nondeformable.

Environmental protection.

Recycling and reuse,repeated times more than 30 times.

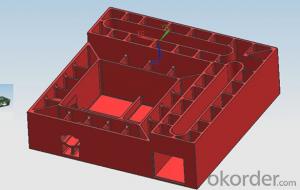

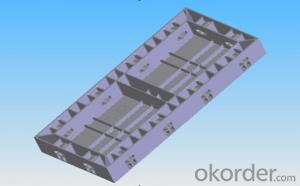

Small deformation, high stiffness, bearing capacity is strong.

Can be processing, can be saw, plane, can be nailed.

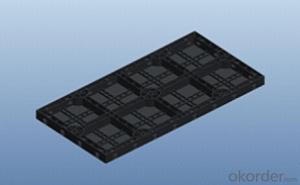

One smooth surface,and one decorative pattern surface.

Smooth surface can make the concrete tamping body smooth and level off, without secondary plaster, save material and time, reduce the cleaning and maintenance cost, used in damp environment such as basement and bridge piers.

Decorative Pattern is helpful to combine with plaster layer, special diffuse reflection effect of the light, avoid strong light reflection.

Comprehensive use of cost :Kaili Lang PP hollow concrete template than ordinary wooden template can save more than 30%.

Item | Kaili Lang PP Hollow Concrete Template (A) | Ordinary Wooden Template (B) | Ordinary Bamboo Template (C) | Comparative advantage |

Thickness(mm) | 15 | 15 | 15 | Equal |

Weight(kg/㎡) | ≦10 | 11.6 | 12.7 | A better than B\C |

Repeated Times | 30-40 | 3-5 | 4-7 | A better than B\C |

Impact Strength | High | Low | Low | A better than B\C |

Range of Application | Wall\Pillar\Girder \ Slate\Bridge | Wall\Pillar\Girder\Slate | Wall\Pillar\Girder\Slate | A better than B\C |

Surface Quality | Flat and Glabrous | Roughness | Roughness | A better than B\C |

Efficiency of Construction | High | Low | Low | A better than B\C |

Abrasive Resistance | Antiwear | No Wear | No Wear | A better than B\C |

Recyclable | Yes | No | No | A better than B\C |

Maintenance Charge | None | A Release Agent is required | A Release Agent is required | A better than B\C |

Corrosion Resistance | Acid and Alkali Resistant | No | No | A better than B\C |

Drop Test(10m) | Not Broken | Broken | Broken | A better than B\C |

Hydroscopicity & Deformation | Nonabsorbent & Nondeformable | Water Absorption & Deformation | Water Absorption & Deformation | A better than B\C |

Environmental Pollution | No Pollution | Pollution | Pollution | A better than B\C |

Advantages of hollow plastic construction templates

Stable product quality

The new hollow plastic construction templates produced by Kaili Lang Technology have canonical size, less deformation, high stiffness, strong bearing capacity, acid/alkali resistance. It will not be deformed after long time’s immersion of water, and can make the quality of architectural structure more stable. Both of architectonic size’s accuracy and the concrete’s qualified rate which adopted by the new hollow plastic building construction template system are above the national standard.

Energy-Efficient Innovation

The new hollow plastic construction template produced by Kaili Lang Technology adopts different surface treatment technology which can make templates have smooth and pattern side in the same time. It can meet fair-faced decoration requirement and save the cost of two coat work if we use smooth side during our construction; If we use pattern side, we can not only met the fair-faced decoration requirement, but also reduced the thickness of floated coat because the pattern increased the binding between concrete and floated coat. It simplified the construction difficulty and made assembly and disassembly of components more easy and simple. Thus the technical requirement for workers is not high, and there’s no dependence of equipments. There’s also no need of brushing release agent, which has greatly improved the efficiency, shortened the construction period, reduced the manpower cost and saved the material cost.

Economic benefit

The new hollow plastic construction templates produced by Kaili Lang Technology turnover time can more than 30 times, which reduced 12% work compared to the traditional wood templates. The comprehensive cost can reduced more than 30% and obviously reduced the usage of construction material such as river sand, wood, cement, and reduced the production of construction waste. It have paid an unprecedented role in energy saving and emission reduction.

Social benefit

In present, most templates used in Chinese building engineering are wooden templates. In 2011, wooden templates’ market scale has more than 300 million square meters, which need to cut 16 million trees whose diameter is more than 30cm. It means to use 10,000 hectare to meet the market demand for wood templates. With the continuous increase of building quantity, which also increased at the rate of at least 10%, the massive usage of wooden templates not only destroys forest resources, but the subsequent waste will cause the secondary environmental pollution. The new hollow plastic construction templates produced by Kaili Lang Technology adopt high-tech production process. All product raw materials are from the production and processing of secondary materials. All obsolete templates after clients’ use can be recovered and reused, which means a real energy and environmental revolution.

- Q:Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q:What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q:Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q:How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q:Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q:I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template construction is convenient, high efficiency: aluminum alloy building template system assembly is simple, convenient, average weight 30KG / m2, completely assembled by the artificial, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer Easy to install), skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold workers only need to install wood workers 70-80%, and do not need skilled workers, just install Before the construction of the staff can be a simple training can be).

- Q:Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q:Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Personally feel that PVC sheet deformation has more reasons. The main reasons are as follows.Pvc plate deformation are: physical deformation and chemical deformation.1. Physical deformation, cause:High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems. Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the root causes.2. Chemical deformation: mainly the molecular structure of raw materials change.

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q:Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hollow plastic construction formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords