High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality and Stainless Alloyed Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality and Stainless Alloyed Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality and Stainless Alloyed Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications for Stainless Alloyed Flat Bar

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

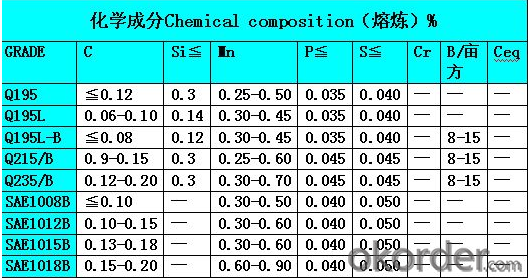

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q:Can steel flat bars be used for creating partitions or room dividers?

- Yes, steel flat bars can be used for creating partitions or room dividers. Steel flat bars are strong and durable, making them an excellent choice for constructing sturdy dividers. They can be easily cut and shaped to desired dimensions, allowing for customized designs. Steel flat bars also provide a modern and industrial aesthetic, adding a stylish touch to any interior space. Additionally, steel is fire-resistant, which enhances safety when used as room dividers. Overall, steel flat bars are a versatile material that can be effectively utilized for creating partitions or room dividers.

- Q:How do steel flat bars contribute to the overall sustainability of infrastructure projects?

- Steel flat bars contribute to the overall sustainability of infrastructure projects in several ways. Firstly, they are durable and long-lasting, which means they require minimal maintenance and replacement over time, reducing the need for additional resources. Secondly, steel is a highly recyclable material, so at the end of its lifespan, flat bars can be recycled and reused in other projects, reducing waste and conserving natural resources. Additionally, steel flat bars have a high strength-to-weight ratio, meaning they can support heavy loads while requiring less material, which helps to reduce the overall carbon footprint of infrastructure projects.

- Q:Can steel flat bars be used in high-temperature environments?

- No, steel flat bars are not suitable for use in high-temperature environments as they tend to lose their strength and structural integrity at elevated temperatures.

- Q:Can steel flat bars be used in outdoor applications?

- Steel flat bars are indeed viable for outdoor applications. Given steel's exceptional durability and resistance to weather, it is well-suited for a range of outdoor settings. Construction, landscaping, and outdoor furniture production often rely on steel flat bars due to their ability to endure moisture, sunlight, and extreme temperatures. Consequently, these bars prove ideal for outdoor use. Moreover, steel can be further fortified against corrosion through treatment or coating, ensuring even greater longevity when employed in outdoor scenarios.

- Q:What are the different methods of joining steel flat bars?

- There exist multiple techniques for connecting steel flat bars, each having distinct advantages and constraints. 1. The most typical approach is welding. This involves fusing the edges of the bars together, which then cool and solidify to form a robust bond. Welding offers versatility, with options like arc welding, gas welding, or spot welding. 2. Bolting is another well-liked method. It entails drilling holes in the bars and securing them with bolts and nuts. Bolting allows for easy disassembly and reassembly, making it suitable for temporary connections or situations requiring frequent maintenance. 3. Riveting involves using metal fasteners called rivets to join the bars. A hole is drilled through the bars, and a rivet is inserted and secured by hammering or mechanical pressing. Riveting provides a strong and permanent connection, but it demands specialized tools and skills. 4. Adhesive bonding is a method employing industrial adhesives to connect steel flat bars. The adhesive is applied to the surfaces, and pressure is applied to achieve a robust bond. Adhesive bonding can be a viable alternative when welding is unsuitable or when a more visually appealing joint is desired. However, its bond strength may be lower compared to welding or mechanical fastening methods. 5. Mechanical fasteners, such as screws, nails, or clips, can also be used to join steel flat bars. These fasteners are inserted into pre-drilled holes or slots in the bars and tightened to secure the connection. While mechanical fasteners offer quick assembly and disassembly, their strength may not match that of welding or riveting. When choosing the appropriate method for joining steel flat bars, it is crucial to consider factors like the intended use, load-bearing requirements, aesthetics, and ease of assembly. Each method has its own advantages and constraints, and the best choice will depend on the specific application.

- Q:Are steel flat bars suitable for earthquake-resistant structures?

- Steel flat bars can be suitable for earthquake-resistant structures depending on several factors. Steel is a highly ductile and strong material, making it ideal for withstanding seismic forces. Flat bars, in particular, offer several advantages for earthquake-resistant structures. Firstly, steel flat bars have excellent tensile strength, which allows them to absorb and distribute seismic forces more effectively. This property enables the building to flex and bend during an earthquake, rather than experiencing brittle failure. This flexibility helps prevent catastrophic collapse and reduces the risk of injury or loss of life. Secondly, steel flat bars can be easily fabricated and joined together, allowing for efficient construction. This ease of use increases the speed of construction, which can be crucial in earthquake-prone areas where rapid rebuilding is necessary after a seismic event. Furthermore, steel flat bars can be used in various structural elements such as beams, columns, and braces to enhance the overall stability and stiffness of the building. When properly designed and integrated into the structural system, steel flat bars can help resist lateral forces, such as those induced by an earthquake. However, it is important to note that the suitability of steel flat bars for earthquake-resistant structures also depends on other factors such as the design, detailing, and construction practices. Proper engineering and design considerations, including seismic analysis and design codes, are critical to ensure that the structure can withstand the expected seismic forces. Additionally, regular inspection and maintenance of the structure are necessary to identify and address any potential issues or damage that may compromise its earthquake resistance. In conclusion, steel flat bars can be a suitable choice for earthquake-resistant structures due to their high tensile strength and flexibility. However, it is crucial to consider various factors and follow proper design and construction practices to ensure the overall safety and performance of the structure during seismic events.

- Q:What are the different types of steel surface treatments available for flat bars?

- There are several types of steel surface treatments available for flat bars, each serving different purposes and providing various benefits. Some of the common types include: 1. Hot-dip galvanizing: This treatment involves immersing the flat bars in a bath of molten zinc, creating a protective coating that prevents corrosion. It provides excellent corrosion resistance and is often used in outdoor or marine applications. 2. Powder coating: Powder coating involves applying a dry powder to the surface of the flat bars and then heating it to form a durable and decorative coating. This treatment provides excellent resistance to chipping, scratching, and fading, making it suitable for applications where aesthetics and durability are important. 3. Electroplating: In electroplating, a thin layer of metal is deposited onto the surface of the flat bars using an electric current. Common metals used for electroplating include chrome, nickel, and zinc. This treatment enhances the appearance of the flat bars and provides corrosion resistance. 4. Passivation: Passivation is a chemical treatment that removes impurities and contaminants from the surface of the steel, improving its corrosion resistance. This treatment is commonly used for stainless steel flat bars to enhance their resistance to corrosion and staining. 5. Shot blasting: Shot blasting involves propelling small steel balls or other abrasive materials at high speeds onto the surface of the flat bars. This treatment removes rust, scale, and other impurities, creating a clean and textured surface that improves adhesion of coatings or paints. 6. Acid pickling: Acid pickling is a process where the flat bars are immersed in an acid solution to remove scale, rust, and other impurities from the surface. This treatment improves the appearance and cleanliness of the flat bars, making them more suitable for subsequent processes like painting or plating. It is important to choose the appropriate surface treatment based on the specific requirements of the application, such as the desired level of corrosion resistance, aesthetics, or durability. Consulting with a professional or a steel supplier can help determine the most suitable treatment for flat bars in a particular use case.

- Q:What are the weight and load-bearing capacities of different steel flat bar sizes?

- Steel flat bars can have varying weight and load-bearing capacities depending on their size. Generally, the larger the flat bar, the greater its weight and load-bearing capacity. Below are some common sizes of steel flat bars and their approximate weight and load-bearing capacities: 1. For a thin flat bar that is 1/8 inch thick, it is typically used for lighter applications. Its weight can range from around 0.42 pounds per foot, and its load-bearing capacity is approximately 200 pounds per foot. 2. If the flat bar is slightly thicker at 1/4 inch, it can handle heavier loads. It typically weighs around 0.85 pounds per foot and has a load-bearing capacity of about 400 pounds per foot. 3. A thicker option is the 3/8 inch steel flat bar, which can support even greater loads. Its weight can range from around 1.27 pounds per foot, and its load-bearing capacity is approximately 600 pounds per foot. 4. Significantly thicker, the 1/2 inch steel flat bar is commonly used for heavy-duty applications. It weighs around 1.7 pounds per foot and has a load-bearing capacity of about 800 pounds per foot. 5. For extremely heavy loads, the 1 inch thick steel flat bar is suitable. It typically weighs around 3.4 pounds per foot and has a load-bearing capacity of approximately 1600 pounds per foot. It is important to note that these weight and load-bearing capacities are approximate and can vary based on the grade and quality of the steel used. Other factors such as the length and support conditions of the flat bar should also be considered when determining its maximum load-bearing capacity. It is advisable to consult professional engineers or refer to load tables provided by steel manufacturers for accurate and specific information on the weight and load-bearing capacities of steel flat bars.

- Q:What is the difference between a steel flat bar and a steel square tube?

- A steel flat bar is a long, rectangular-shaped piece of steel that is typically used for structural support or as a base for various applications. It has a flat surface on all sides and is available in various thicknesses. On the other hand, a steel square tube is a hollow, square-shaped piece of steel with equal sides. It is commonly used for constructing frameworks, supports, or as a protective enclosure. The hollow design of the tube allows for easier routing of wires or other materials inside. In summary, the main difference between a steel flat bar and a steel square tube lies in their shape and purpose. While a flat bar provides structural support with a flat surface, a square tube offers a hollow configuration for versatile applications.

- Q:How do you store steel flat bars to prevent damage?

- To prevent damage to steel flat bars, it is recommended to store them in a dry and well-ventilated area to avoid moisture buildup and corrosion. Additionally, they should be stacked horizontally with proper support to prevent bending or warping. Using protective covers or separating each bar with wooden or rubber spacers can prevent scratching or damage from contact with other materials. Regular inspection and maintenance are also essential to ensure their longevity and quality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords