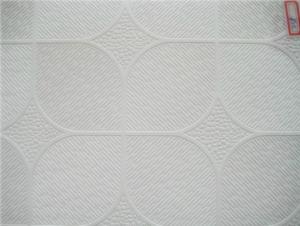

Gypsum Ceiling PVC Laminated 991 Gypsum Ceiling PVC Laminated 991

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

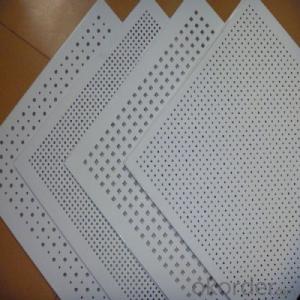

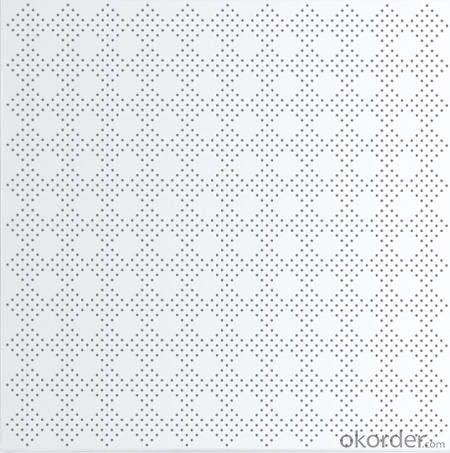

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

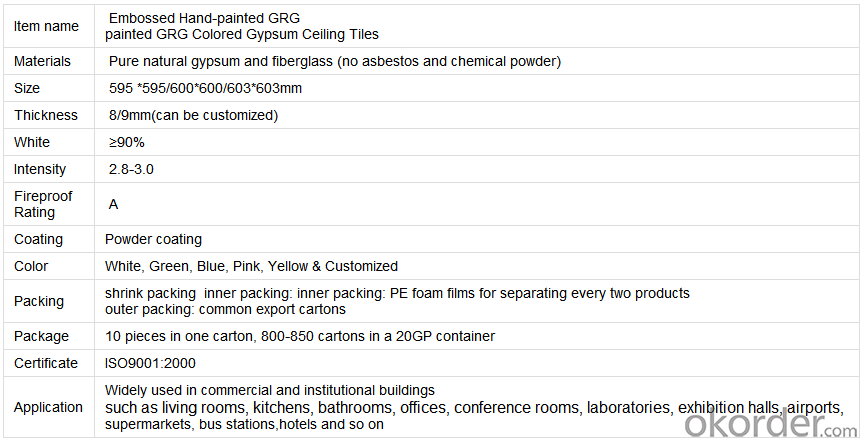

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

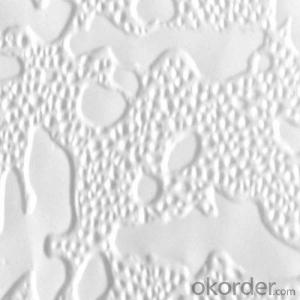

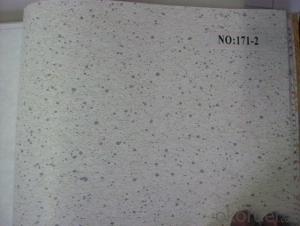

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q:Gypsum board linear ceiling, L-type linear ceiling what is the difference

- L-type is a simple straight or back to the type of ceiling, suitable for simple decoration style. Gypsum board straight ceiling ceiling is usually 600 * 600, with a protruding pattern, with 38 main bone and T bone assembly.

- Q:How do I install the ceiling?

- Ceiling decoration, decoration works is the first work. From the process point of view, generally start from the construction of the ceiling. But the ceiling is often the place where users and most designers and engineering contractors are ignored. Ceilings, also known as ceiling or ceiling and ceiling. Ceiling decoration materials are the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, plywood ceilings, profiled long strip of aluminum slab ceilings, square painted lacquered lap plate ceiling, stained glass ceilings, etc. The Such as the use of aluminum slab to do the smallpox, usually called "aluminum cords board ceiling." Various ceilings have different characteristics.

- Q:My house is a prefabricated board and is a kind of old tile-roofed plaster ceiling can you, life is how much?

- Yes, you can use the long boom to connect the keel. Do the ceiling without any technical obstacles. As for the life, it depends on the quality of the house, the house did not leak, ceiling use 25 to 30 years is not any problem. I hope my solution will help you

- Q:Bathroom gypsum board ceiling did not leave the mouth how to do

- Generally do not have problems, if you really want to repair, open a square hole, and then cover the pvc cover on the line.

- Q:Gypsum board ceiling hanging good, can cut off part?

- Just say a word that theoretically said it is possible to see you on the actual effect of the degree of care! For example, when the original time is symmetrical or have other intentions, then there is no way to know. You can contact the original decoration of the construction team once in place it! And the price and talk!

- Q:Living room ceiling above the installation of downlights, the ceiling is the first hole and then paint, or the first paint, and then open the lamp ah?

- Even the first hole is the first hole and then paint, so I bought the lamp in advance.

- Q:The distance between the curtains of the Roman rod and the ceiling or gypsum line should be appropriate?

- When the Roman curtain rod is mounted on the wall, the Roman pole is about 6-300px away from the ceiling or gypsum line, so as to avoid repression and suffocation. When installed on the roof or ceiling, the Roman pole leaves the wall about 6-250px, Time, friction wall, fouling curtain fabric.

- Q:What is the name of this type of gypsum board ceiling? How I check the gypsum ceiling on the Internet are several square one, there is no such small pieces.

- You about the aluminum plate

- Q:I have recently used gypsum to close a whole between the ceiling and the fireplace's stainless steel pipes. The gypsum comes in contact with the pipes. The pipes, as expected become very hot when the fireplace is lit. I am wondering if the gypsum may have any corrosive effects on the pipes. In the case of damage it will almost be impossible to replace the pipes, but i could possibly remove the gypsum while there is time! Your input much appreciated!

- stainless steel is impervious to most things. gypsum shouldn't have any effect

- Q:Home decoration of the ceiling gypsum board thick

- According to the national regulatory requirements, the current market with the gypsum board decorated with gypsum board, no gypsum board, water gypsum board and fire gypsum board. The nominal thickness of the four gypsum boards is 9.5 mm and 12 mm. The thickness of the product produced by each manufacturer is different. Therefore, the thickness of the 9.5 mm plate is generally between 9.0 and 10.5 mm, and the thickness of the 12 mm plate is generally 11.5 to 12.5 mm. Home decoration generally use 9.5 mm gypsum board, ceiling with 9.5 mm plaster board can be a single layer. 9.5 square meters of gypsum board market price (for reference): 25 ~ 30 yuan / square meter; 12.5 mm gypsum board market price (for reference): 29 ~ 35 yuan / square meter; 9.5 mm paperless gypsum board Market price (for reference): 11 yuan / square meters; 12.5 mm no gypsum board market price (for reference): 14 yuan / square meters; the above price does not include keel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gypsum Ceiling PVC Laminated 991 Gypsum Ceiling PVC Laminated 991

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords