GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

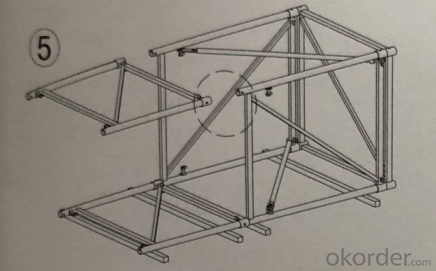

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

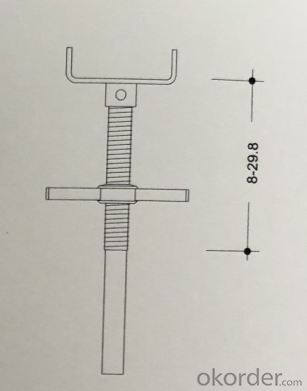

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

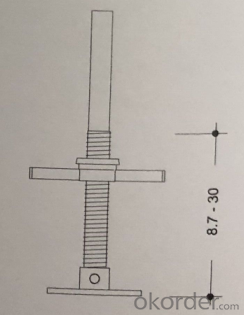

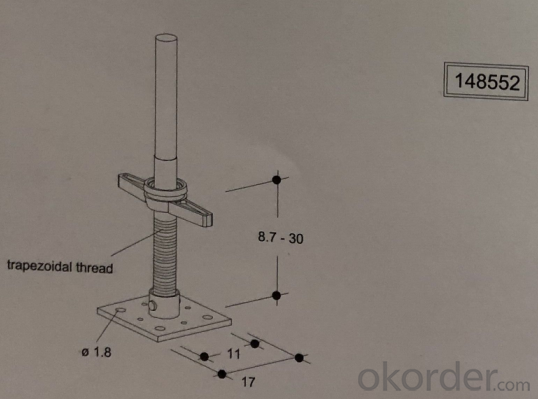

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

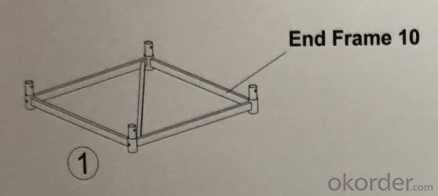

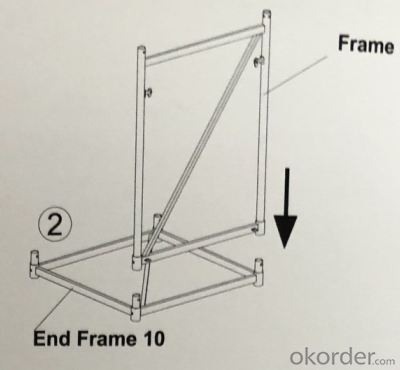

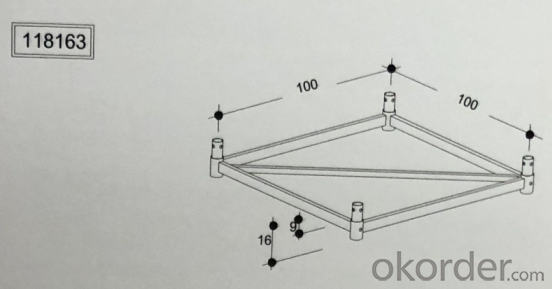

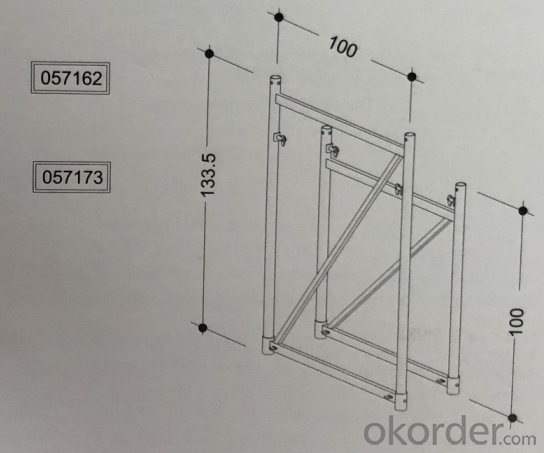

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

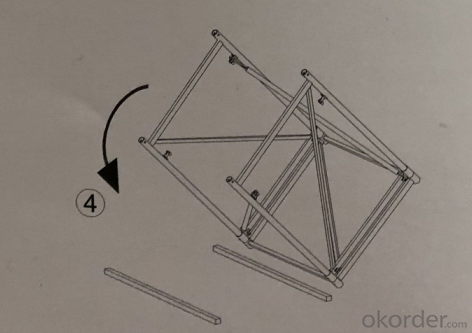

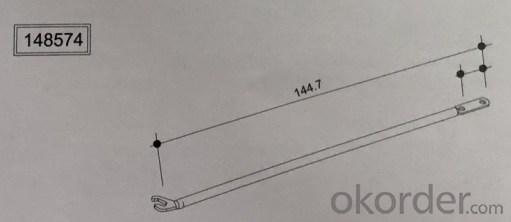

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q:Can steel props be used in foundation repair work?

- Yes, steel props can be used in foundation repair work. Steel props are commonly used in construction and can provide the necessary support to stabilize and reinforce foundation structures during repair processes.

- Q:Are steel props suitable for supporting elevated walkways?

- Indeed, elevated walkways can be effectively supported by steel props. Steel, being a robust and long-lasting material, possesses the essential strength and stability needed for walkways situated at elevated heights. In construction and civil engineering undertakings, steel props are widely utilized to provide support to various structures, including walkways, bridges, and platforms. These props are ingeniously engineered to withstand substantial loads and to ensure the safety of pedestrians utilizing the walkways. Moreover, the adaptability of steel props enables effortless installation and the accommodation of diverse heights and configurations of walkways. All in all, steel props are a dependable and appropriate option for supporting elevated walkways.

- Q:Are steel props more expensive than other support systems?

- It depends on the specific requirements and context. Steel props can be more expensive than other support systems in some cases due to their durability, strength, and versatility. However, other support systems may be more cost-effective for certain applications depending on factors such as load capacity, project duration, and accessibility. Ultimately, the cost comparison should be based on the specific needs of the project.

- Q:Are there any regulations or guidelines for using steel props in construction?

- Yes, there are regulations and guidelines for using steel props in construction. Steel props, also known as adjustable steel props or acrow props, are temporary support structures used to provide vertical support during construction or renovation projects. These props are commonly used to support walls, floors, ceilings, or other structures. In many countries, the use of steel props in construction is regulated by local building codes and standards. These regulations ensure the safety and stability of structures and protect workers and users of the building. The specific regulations may vary depending on the jurisdiction, but they generally cover aspects such as design, installation, maintenance, and load-bearing capacities. One widely recognized guideline for using steel props is the European Standard EN 1065, which provides specifications for adjustable steel props used in temporary structures. This standard defines various technical parameters such as the maximum load capacity, permissible deflection, and adjustment range for different prop sizes. Compliance with this standard helps ensure that steel props are used safely and effectively. Additionally, construction companies and contractors often follow industry best practices and guidelines provided by professional organizations or trade associations. These guidelines may provide recommendations on the proper use, installation, inspection, and maintenance of steel props. It is crucial to follow these guidelines to ensure that the props are used correctly, and any potential risks or hazards are minimized. In conclusion, the use of steel props in construction is subject to regulations and guidelines that aim to ensure their safe and effective use. Compliance with local building codes, standards such as EN 1065, and industry best practices is crucial to maintain the structural integrity and safety of construction projects. It is essential for construction professionals to stay updated with the latest regulations and guidelines to ensure compliance and promote safe construction practices.

- Q:How do steel props compare to timber beams in terms of performance?

- Different applications require the use of steel props and timber beams due to their distinct characteristics and performance capabilities. Steel props, which are also known as adjustable steel props or acrow props, are commonly utilized in construction to provide temporary support for loads like formwork and scaffolding. These props are made from high-quality steel and can be adjusted to various lengths, offering versatility and adaptability. With a high load-bearing capacity, they are capable of withstanding substantial weights, making them suitable for heavy-duty tasks. Additionally, steel props provide excellent stability and are resistant to warping or bending, ensuring consistent performance. Conversely, timber beams find frequent use in residential construction and other scenarios where aesthetics and cost-effectiveness are significant factors. These beams are lightweight and easy to handle, making them ideal for smaller-scale projects. Moreover, they possess good insulation properties, making them suitable for applications where thermal efficiency is essential. However, timber beams have lower load-bearing capacities than steel props and are more susceptible to warping, rotting, and termite damage. In terms of performance, steel props are generally regarded as more reliable and durable compared to timber beams. They are capable of supporting heavier loads, providing greater stability and safety in construction projects. Additionally, steel props are reusable and require less maintenance, making them a cost-effective option in the long run. However, in certain situations where aesthetics and cost are prioritized over load-bearing capacity, such as in residential construction or interior design projects, timber beams may still be preferred. Ultimately, the selection between steel props and timber beams depends on the specific requirements of the project, including load-bearing capacity, durability, cost, and aesthetic considerations. Consulting with professionals and carefully considering the project's needs is essential before making a decision.

- Q:Do steel props require any maintenance?

- Regular maintenance is necessary for steel props to ensure they function properly and remain safe. Maintenance tasks for steel props may include the following: 1. Clean the steel props regularly by using a brush, water, and mild detergent to remove dirt, debris, or any substances that could affect their performance. 2. Inspect the steel props on a regular basis to check for signs of damage such as cracks, dents, or corrosion. Any damaged props should be immediately replaced. 3. Apply lubrication to movable parts of the steel props, such as adjustable screws or pins, to prevent them from seizing or becoming stiff. This will ensure easy and smooth adjustment when necessary. 4. Store the steel props properly when not in use to prevent rust or damage. This may involve keeping them in a dry and well-ventilated area, away from moisture or chemicals that could cause corrosion. 5. Periodically test the steel props to ensure they can bear the specified load capacity. This can be done using load testing equipment or by following the manufacturer's guidelines. Following the manufacturer's instructions and guidelines for maintenance is crucial to ensure the longevity and safe usage of steel props. Regular maintenance and inspection also help in identifying potential issues early on, reducing the risk of accidents or failures during use.

- Q:How do you calculate the required height of steel props for a project?

- To calculate the required height of steel props for a project, you need to consider the load-bearing capacity of the props and the weight they will be supporting. The formula is typically: Required Height = (Load / Safe Load Capacity) + Beam Height. By determining the load and the safe load capacity of the props, you can then calculate the height needed to adequately support the weight. Additionally, the beam height should be factored in to ensure proper alignment and stability.

- Q:Are steel props resistant to fire and heat?

- Yes, steel props are generally resistant to fire and heat due to the high melting point and thermal conductivity of steel.

- Q:How is the height of a steel prop adjusted?

- To adjust the height of a steel prop, one can utilize an adjustable collar or tube that is connected to the prop. This collar or tube can be maneuvered along the length of the prop to attain the desired height. By turning the collar in a specific direction, it can be loosened, enabling the prop to be extended or retracted to the desired height. Once the desired height is achieved, the collar can be tightened by turning it in the opposite direction, securing the prop at that height. This mechanism of adjustment facilitates effortless and accurate height modifications, thus making steel props a favored option for temporary support structures in construction and scaffolding applications.

- Q:Can steel props be used in the construction of water treatment plants or reservoirs?

- Yes, steel props can be used in the construction of water treatment plants or reservoirs. Steel props, also known as adjustable steel props or steel shore supports, are commonly used in construction projects to provide temporary support to structures. In the context of water treatment plants or reservoirs, steel props can be used to support formwork, scaffolding, or temporary platforms during the construction process. They are especially useful in scenarios where there is a need for temporary support due to changes in water levels or the construction of concrete structures. Steel props offer a high load-bearing capacity, durability, and flexibility, making them suitable for the challenging conditions often encountered in the construction of water treatment plants or reservoirs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords