Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

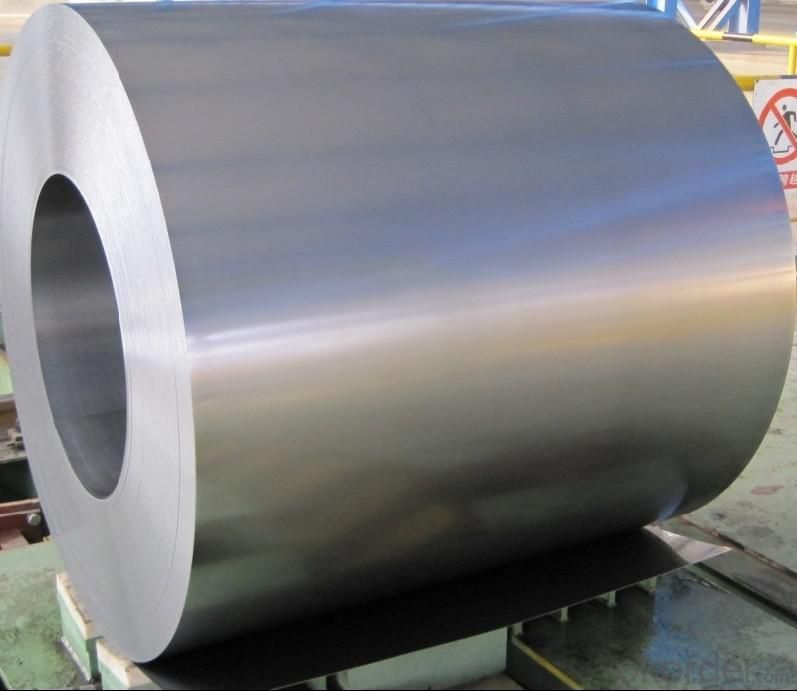

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How do steel sheets perform in terms of fatigue resistance?

- Steel sheets generally have excellent fatigue resistance. Due to their high strength and durability, steel sheets can withstand repeated cyclic loading without significant damage or failure. The fatigue resistance of steel sheets is attributed to the material's ability to absorb and distribute stress, preventing the accumulation of cracks or fractures. Additionally, steel sheets can be further enhanced through various heat treatment processes, such as quenching and tempering, which improve their fatigue resistance properties. Therefore, steel sheets are often preferred in applications where fatigue resistance is crucial, such as in the automotive and aerospace industries, as they can withstand prolonged and repeated loading without compromising their structural integrity.

- Q:How do steel sheets perform in terms of impact resistance?

- Steel sheets are known for their exceptional impact resistance. Due to their high strength and rigidity, steel sheets are able to withstand significant impacts without deformation or failure, making them highly reliable and suitable for various applications where impact resistance is crucial.

- Q:What are the different shapes available for steel sheets?

- There are several different shapes available for steel sheets, depending on the specific requirements and applications. Some of the commonly used shapes include: 1. Flat sheets: These are the most basic and versatile shape of steel sheets. They have a flat surface and are available in various sizes and thicknesses. Flat sheets are commonly used in construction, automotive, and manufacturing industries. 2. Coils: Steel sheets can also be available in coils, which are continuous lengths of sheet metal wound into a roll. Coils are often used for large-scale production processes, such as in the manufacturing of appliances, automobiles, and HVAC systems. 3. Perforated sheets: These sheets have evenly spaced holes or perforations throughout their surface. Perforated sheets are used in applications where ventilation, filtration, or aesthetic appeal is required, such as in architectural designs, signage, and industrial machinery. 4. Corrugated sheets: These sheets have a series of parallel ridges and grooves, which provide strength and rigidity. Corrugated sheets are commonly used for roofing and siding applications, as they offer excellent durability and weather resistance. 5. Expanded metal sheets: These sheets are manufactured by cutting and stretching a flat sheet, creating a pattern of diamond-shaped openings. Expanded metal sheets are used in applications that require ventilation, security, or filtration, such as fences, walkways, and machine guards. 6. Diamond plate sheets: Also known as tread plate or checker plate, these sheets have a pattern of raised diamonds or lines on their surface. Diamond plate sheets are commonly used for flooring, stairs, ramps, and truck bed liners, as they provide traction and slip resistance. These are just a few examples of the different shapes available for steel sheets. The choice of shape depends on the specific requirements of the project, including strength, durability, aesthetics, and functionality.

- Q:Are steel sheets resistant to impact and abrasion?

- Yes, steel sheets are generally resistant to both impact and abrasion due to their high strength and durability. They can withstand heavy loads and are less prone to denting or scratching, making them suitable for applications that require protection against impacts and abrasions.

- Q:What is the average moisture resistance of steel sheets?

- The average moisture resistance of steel sheets can vary depending on the specific type of steel and its protective coatings. Generally, steel sheets have good moisture resistance due to their inherent corrosion resistance properties. However, the resistance can be further enhanced by applying various surface treatments such as galvanization, which adds a layer of zinc to protect against moisture and corrosion. In terms of specific values, it is difficult to provide an exact average moisture resistance without considering the specific steel grade, thickness, and coating. Typically, steel sheets with galvanized coatings can provide excellent moisture resistance, with some studies reporting corrosion rates as low as 0.1-0.5 micrometers per year in highly corrosive environments. It is crucial to note that the performance of steel sheets in resisting moisture can also be influenced by other factors such as the presence of scratches, cuts, or exposure to chemicals. Regular maintenance, inspection, and proper handling of steel sheets can help ensure their optimal moisture resistance over time.

- Q:Can steel sheets withstand high temperatures?

- Yes, steel sheets can withstand high temperatures.

- Q:Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a versatile and durable material that is commonly used in the fabrication of various agricultural machinery and equipment. It is known for its strength, rigidity, and resistance to wear and tear, making it suitable for heavy-duty applications in farming and agriculture. Steel sheets can be used to manufacture a wide range of agricultural equipment, such as plows, cultivators, seeders, harvesters, trailers, and storage containers. These equipment require sturdy materials to withstand the demanding conditions of the agricultural environment, including exposure to soil, moisture, and heavy loads. Steel sheets can be formed and manipulated into different shapes and sizes, allowing for the customization of agricultural equipment to meet specific requirements. Additionally, steel can be easily welded, ensuring the structural integrity of the equipment and enabling repairs if necessary. Furthermore, steel sheets can be coated or galvanized to enhance their corrosion resistance, further increasing their longevity and durability in agricultural applications. This helps to protect the equipment from rust and deterioration caused by exposure to various weather conditions and chemicals commonly found in farming activities. Overall, steel sheets are a suitable material for agricultural equipment due to their strength, durability, and versatility. Their use in the manufacturing of agricultural machinery helps to ensure reliable and efficient performance, contributing to the productivity and success of farming operations.

- Q:How are steel sheets priced?

- Steel sheets are typically priced based on factors such as the type and grade of steel used, the size and thickness of the sheet, market demand and supply, and any additional processing or finishing required.

- Q:What are the common lengths of steel sheets?

- The common lengths of steel sheets vary depending on the specific industry and application, but they typically range from 6 to 12 feet.

- Q:Can steel sheets be used for conveyor belts?

- Yes, steel sheets can be used for conveyor belts. Steel is a versatile and durable material that can withstand heavy loads and high temperatures, making it suitable for conveyor belt applications. Steel sheets can be fabricated into various shapes and sizes, allowing for customization based on the specific conveyor system requirements. Additionally, steel sheets offer excellent resistance to wear, impact, and corrosion, ensuring a longer lifespan for the conveyor belt. Overall, steel sheets provide a reliable and robust solution for conveyor belt applications in industries such as manufacturing, mining, and logistics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords