GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

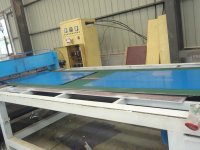

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

our corrugated steel sheet:

GI Corrugated Steel Sheet | ||

No. | Item | Specification |

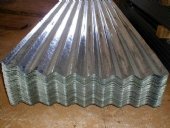

1 | Product Name | GI corrugated steel roofing sheet |

2 | Effective Width | 650mm to 1250mm |

3 | Thickness | 0.13mm-0.8mm |

4 | Material | Aluzinc or zinc coating PPGI steel coil |

5 | Zinc-coating | 40g/m2-150g/m2 |

6 | Color | white,blue or any RAL colors |

7 | length | 1m-11.8m according to the container |

8 | top color coating | 12um-25um |

9 | Back color coating | 7um-10um |

10 | HRB | 50-95 |

11 | Certificate system | ISO9001:2000 |

12 | base plate | hot-dipped galvanised steel sheet |

13 | Characters | light weight. Waterproof and fireproof and easy construction |

14 | Stardard | ASTM,JIS, DIN, GB |

- Q:Can steel sheets be used in acidic environments?

- In acidic environments, steel sheets can be utilized, but it is crucial to select the appropriate steel and take necessary precautions. Stainless steel, especially grades containing high levels of chromium and nickel, exhibits remarkable resistance against corrosion and can endure acidic environments. When these steel sheets come into contact with oxygen, they develop a passive protective layer on their surface, which halts further corrosion. Nevertheless, not all steel types are suitable for acidic environments. Carbon steel, for instance, is susceptible to corrosion under acidic conditions and is not recommended for such applications. Furthermore, the concentration and temperature of the acid can impact the performance of steel sheets. To ensure optimal performance in acidic environments, it is advisable to seek advice from steel suppliers or corrosion engineers who can suggest the most suitable steel type for specific conditions. Regular monitoring and maintenance of the steel sheets are also important to prevent any potential damage or corrosion.

- Q:Excuse me, what's the difference between cold rolled steel plate and hot plate in steel plate?

- In general, cold rolled steel has better strength, hot rolled steel plate has better ductility. The general thickness of cold rolled is relatively small, can have a larger thickness. Cold rolled steel plate surface quality, appearance and dimensional accuracy than the hot plate, and the thickness of the product right rolling thin to about 0.18mm, so it is popular for. The acceptance of the products, can ask professional personage.

- Q:Can steel sheets be used for manufacturing storage cabinets?

- Yes, steel sheets can be used for manufacturing storage cabinets. Steel is a durable and strong material that is commonly used in the construction of cabinets and other storage solutions. Steel sheets can be easily fabricated and formed into the desired shape for the cabinet, and they provide excellent support and stability for storing heavy objects. Additionally, steel is resistant to corrosion, making it suitable for areas with high moisture levels or harsh environmental conditions.

- Q:Can the steel sheets be used for roofing purposes?

- Indeed, steel sheets are suitable for roofing applications. Steel roofing sheets are favored because of their long-lasting nature, robustness, and ability to endure severe weather conditions. They offer superb safeguard against elements like rain, snow, and hail. Moreover, steel roofing sheets possess fire-resistant properties and can endure strong winds, rendering them a dependable choice for roofing needs. Furthermore, steel sheets are lightweight, facilitating easier installation and reducing strain on the structure. They come in diverse designs and colors, enabling customization to suit personal preferences. All in all, steel sheets are a versatile and pragmatic option for roofing purposes.

- Q:What is the process of annealing steel sheets?

- Annealing steel sheets is a heat treatment process that involves heating the sheets to a specific temperature, typically above its recrystallization temperature, and then slowly cooling it down. This process helps to relieve internal stresses, soften the steel, and improve its ductility and machinability. The slow cooling allows the formation of larger grains, resulting in a more uniform and malleable material.

- Q:How are steel sheets cleaned and maintained?

- Steel sheets can be cleaned and maintained using various methods depending on the specific requirements and conditions. Here are some common practices to clean and maintain steel sheets: 1. Regular cleaning: Steel sheets should be cleaned regularly to remove dust, dirt, and other debris that may accumulate on the surface. This can be done using a soft cloth or sponge with mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. 2. Rust removal: If rust spots appear on the steel sheets, they should be promptly removed to prevent further corrosion. Rust can be removed using a wire brush, sandpaper, or a rust remover solution. Afterward, the area should be thoroughly cleaned and dried. 3. Protective coating: Applying a protective coating can help prevent rust and corrosion, especially for steel sheets exposed to harsh environments or moisture. This can be done using paint, varnish, or a specialized anti-corrosion coating. The coating should be applied according to the manufacturer's instructions and reapplied periodically as needed. 4. Proper storage: Steel sheets should be stored in a dry and well-ventilated area to prevent moisture buildup and corrosion. They should be kept away from direct contact with the ground and other metals to avoid galvanic corrosion. Additionally, using covers or protective wraps can further safeguard the sheets from dust and other contaminants. 5. Periodic inspection: Regularly inspecting steel sheets for any signs of damage, such as dents, scratches, or cracks, is essential. If any damage is found, it should be repaired promptly to prevent further deterioration. 6. Professional maintenance: For large-scale or complex steel sheet installations, it may be necessary to hire professional maintenance services. These experts have the knowledge, tools, and experience to handle more extensive cleaning, maintenance, and repairs. By following these cleaning and maintenance practices, steel sheets can maintain their integrity, appearance, and performance over time.

- Q:What is the shelf life of steel sheets?

- The shelf life of steel sheets is typically considered to be indefinite. Unlike perishable goods, steel sheets do not have an expiration date or a limited lifespan. Properly stored and maintained steel sheets can remain in good condition for many years, if not decades, without any significant degradation. However, exposure to certain environmental factors such as moisture, extreme temperatures, and corrosive substances can affect the quality and durability of steel sheets over time. Therefore, it is recommended to store steel sheets in a dry and controlled environment to ensure their longevity and prevent any potential damage or deterioration.

- Q:How do steel sheets perform in terms of corrosion resistance?

- Steel sheets, particularly those that are coated or galvanized, exhibit excellent corrosion resistance due to their inherent properties and protective coatings. The corrosion resistance of steel sheets can be attributed to the presence of iron oxide (rust), which forms a protective layer over the steel, preventing further corrosion. Additionally, various coatings like zinc or paint can be applied to further enhance their resistance against corrosion, making steel sheets a reliable choice for various applications.

- Q:Can steel sheets be used in food processing or pharmaceutical industries?

- Steel sheets are indeed applicable for use in the food processing and pharmaceutical industries. These industries often utilize stainless steel sheets because of their remarkable resistance to corrosion, their durability, and their hygienic properties. Stainless steel, known for being non-reactive and not releasing any harmful substances into food or pharmaceutical products, is frequently employed. Furthermore, its ease of cleaning and maintenance makes it a suitable option for applications that necessitate high levels of cleanliness and hygiene. Moreover, stainless steel sheets are capable of withstanding extreme temperatures and are resistant to impact and abrasion, making them an ideal choice for the food processing and pharmaceutical industries, where stringent quality and safety standards are crucial.

- Q:Can steel sheets be used in outdoor applications?

- Steel sheets are a great option for outdoor applications. They possess exceptional durability and strength, enabling them to withstand diverse weather conditions, thus rendering them suitable for outdoor use. The construction industry heavily relies on steel sheets for roofing, siding, and cladding purposes. Additionally, they are extensively utilized in outdoor storage sheds, fences, and gates. To enhance its corrosion resistance against moisture and environmental elements, steel sheets can be coated with galvanization or painting. Consequently, their ability to withstand exposure to such factors is greatly improved. All in all, steel sheets are an exceedingly dependable choice for outdoor applications, thanks to their strength, durability, and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords