Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

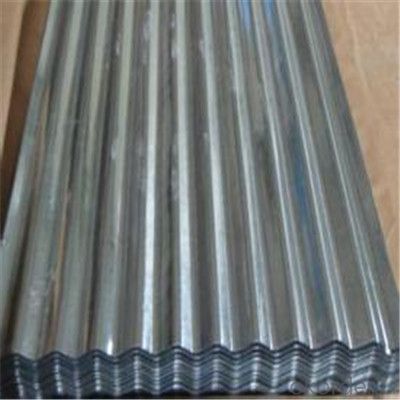

Description of Corrugated Iron Sheet:

Thickness: 0.14-0.8mm

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

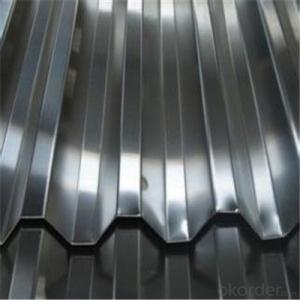

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Surface treatment: chromate, oil/unoil, bright finish, spangle,

Corrugated Sheet Materials: Galvanized steel, Aluzinc Steel, Aluzinc Pre-painted sheet and Aluminium sheet. Gloss: The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

Paint type: PE or PVDF

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:What is the process of polishing steel sheets?

- Achieving a smooth and shiny finish on steel sheets involves a series of steps. Firstly, the surface is cleaned to eliminate any dirt, oil, or debris, typically by employing a degreaser or solvent. Following this, abrasive materials like sandpaper or a sanding belt are utilized to sand the sheets, thus eliminating visible scratches and imperfections. Once sanded, a polishing compound or paste is usually applied and rubbed into the surface with a cloth or buffing wheel. This compound aids in removing any remaining scratches and revealing the natural shine of the steel. To further enhance the shine and smoothness, a finer polishing compound may be employed, repeating the process until the desired level of polish is achieved. Finally, the sheets are meticulously cleaned and inspected to ensure they meet the desired quality standards, including the removal of any remaining polishing compound residue and the identification of any remaining imperfections. In conclusion, the process of polishing steel sheets necessitates careful cleaning, sanding, and polishing to attain a smooth and shiny finish. The specific techniques and materials employed may vary depending on the desired level of polish and the type of steel being polished.

- Q:Can the steel sheets be used for medical equipment?

- Indeed, medical equipment can make use of steel sheets. Steel's robustness, longevity, and resistance to corrosion render it a prevalent substance in the medical sector. It permits the production of an array of medical equipment, including surgical tools, hospital beds, medical trolleys, and diagnostic apparatus. Steel sheets can be conveniently shaped and crafted into diverse forms and dimensions, thereby catering to distinct requirements of medical equipment. Moreover, steel's hygienic attributes, facilitating easy sterilization, establish it as a fitting material for medical equipment necessitating regular sanitization.

- Q:What are the different alloying elements used in steel sheets?

- Some of the commonly used alloying elements in steel sheets include carbon, manganese, silicon, chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added in varying quantities to enhance specific properties of the steel, such as strength, hardness, corrosion resistance, and heat resistance.

- Q:What is the average weight of a steel sheet per square meter?

- The average weight of a steel sheet per square meter can vary depending on the thickness and type of steel being used. However, a general estimate for mild steel sheets is around 7.85 kilograms per square meter. It is important to note that this weight can vary slightly based on the specific composition of the steel and any additional coatings or treatments applied to the sheet.

- Q:Are steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting if they are not adequately protected or exposed to moisture and oxygen.

- Q:What are the dimensions of the steel sheets?

- Depending on specific requirements or intended use, the dimensions of the steel sheets may differ. Standard sizes for steel sheets are often found in dimensions like 4 feet by 8 feet or 1 meter by 2 meters. Nonetheless, customizing the dimensions of the sheets is also possible to cater to project needs. To ensure the steel sheets meet the required specifications, it is crucial to specify the desired length, width, and thickness when placing an order.

- Q:What are the different types of steel sheet finishes for decorative purposes?

- There are several different types of steel sheet finishes that are commonly used for decorative purposes. These finishes are applied to the surface of the steel sheet to enhance its appearance and provide a desired aesthetic effect. Some of the most popular steel sheet finishes for decorative purposes include: 1. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with a fine abrasive material, usually in a straight line pattern. It creates a smooth, satin-like appearance and is often used for architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this finish creates a highly reflective surface that resembles a mirror. It is achieved by mechanically polishing the steel sheet and is commonly used in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the surface of the steel sheet. It can be achieved through various techniques, such as stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: Steel sheets can also be coated with a colored finish to add vibrancy and enhance their visual appeal. This can be achieved through processes such as powder coating, which involves applying a dry powder to the steel sheet and then curing it to create a durable, colored finish. Colored finishes are commonly used in architectural applications, including building facades and signage. 5. Antique Finish: This finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. It is achieved through various techniques such as chemical treatments, patinas, or distressing. Antique finishes are often used in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the different types of steel sheet finishes available for decorative purposes. Each finish offers a unique appearance and can be customized to suit specific design preferences. The choice of finish depends on the desired look, application, and the level of durability required for the project.

- Q:What is the process of manufacturing steel sheets?

- Manufacturing steel sheets encompasses a series of steps. Initially, the necessary raw materials for steel production, including iron ore, coal, and limestone, are acquired. Following this, these materials undergo processing in a blast furnace to generate molten iron. The molten iron is then refined in either a basic oxygen furnace or an electric arc furnace, eliminating impurities and incorporating alloying elements to attain the desired steel composition. Upon completion of the refining process, the steel is cast into slabs or billets, which are subsequently reheated in a furnace until they reach a suitable temperature for rolling. The reheated steel is then fed through a sequence of rolling mills, where it is shaped and its thickness is reduced to form a continuous sheet. The rolling process comprises multiple passes through the mills, gradually diminishing the steel's thickness and enhancing its properties. After the rolling process, the steel sheets are frequently subjected to pickling and treated with various coatings or finishes to enhance their surface quality and resistance to corrosion. Finally, the sheets are cut into specific sizes and may undergo additional processing, such as tempering or annealing, to further enhance their mechanical properties. In summary, the production of steel sheets involves a combination of refining, casting, rolling, and finishing processes to create superior-quality sheets that meet the desired specifications.

- Q:Are the steel sheets suitable for welding or fabrication purposes?

- Yes, steel sheets are suitable for welding or fabrication purposes. Steel is a versatile and commonly used material in various industries, including construction, automotive, and manufacturing. Steel sheets provide a strong and durable base for welding and fabrication processes. They can be easily cut, shaped, and joined together through welding techniques such as arc welding, MIG welding, or TIG welding. Steel sheets also offer excellent structural integrity and can withstand high temperatures and mechanical stress during welding or fabrication. Additionally, steel sheets are available in different thicknesses and grades, allowing for customization based on specific welding or fabrication requirements.

- Q:Can steel sheets be used for manufacturing storage tanks?

- Yes, steel sheets can be used for manufacturing storage tanks. Steel is a commonly used material for storage tanks due to its strength, durability, and resistance to corrosion. Steel sheets can be shaped, welded, and coated to meet the specific requirements of storage tank construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords