Galvanized/Aluzinc Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

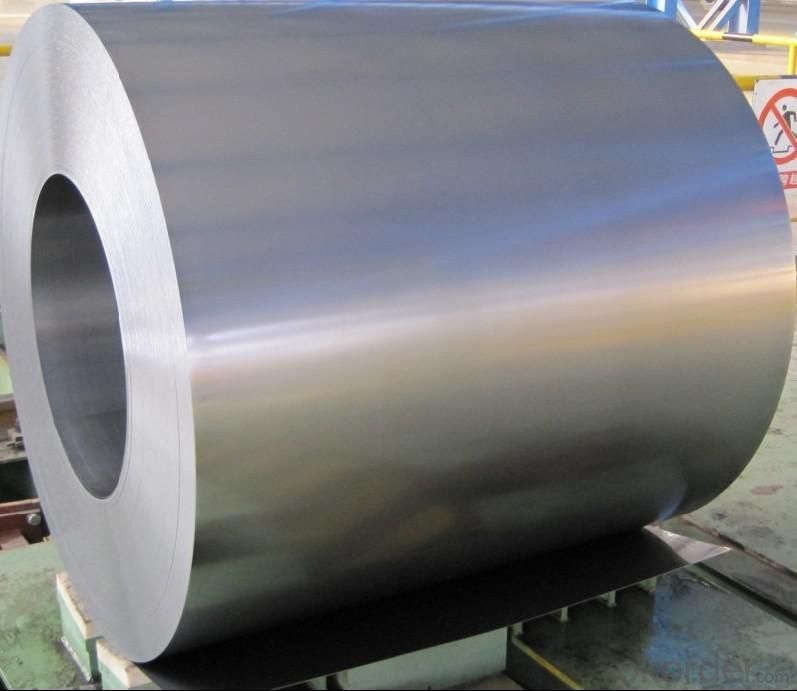

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

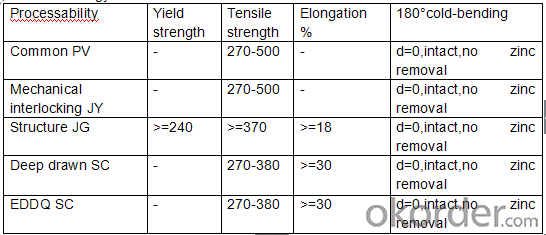

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:The difference between color steel and stainless steel

- Color steel and stainless steel, stainless steel what is the difference? Color of the color is beautiful, diverse styles, economic and handsome, cheaper than stainless steel, the main difference is that the service life is about 3 years. Stainless steel is characterized by

- Q:What are the disadvantages of using steel sheets?

- Some potential disadvantages of using steel sheets are their susceptibility to corrosion, their relatively high cost compared to other materials, and their heavy weight, which can make installation and transportation more challenging. Additionally, steel sheets may require regular maintenance to prevent rust and may not be suitable for certain design aesthetics or applications where a lighter material is desired.

- Q:Are the steel sheets recyclable?

- Yes, steel sheets are recyclable. Steel is one of the most commonly recycled materials worldwide due to its high recycling rate and ease of processing. When steel sheets reach the end of their useful life, they can be collected, sorted, and sent to recycling facilities where they are melted down and transformed into new steel products. Recycling steel sheets not only helps conserve natural resources and reduce energy consumption but also helps reduce waste and minimize environmental impact.

- Q:What is the difference between a satin and mirror finish steel sheet?

- The appearance and level of reflectivity distinguish a satin finish steel sheet from a mirror finish steel sheet. A satin finish steel sheet displays a sleek, non-glossy appearance with a minimal level of reflectivity. Achieved through the use of abrasive materials, it creates a brushed or textured surface. This finish is often favored for its contemporary and subtle aesthetic. Satin finish steel sheets find common usage in architectural and interior design applications, such as kitchen appliances, countertops, and wall panels. On the contrary, a mirror finish steel sheet exhibits an immensely reflective surface that closely resembles a mirror. Achieved by polishing the steel sheet to a high gloss using fine abrasives and buffing compounds, this finish boasts an intense shine and exceptional clarity. It reflects light remarkably, resulting in a glamorous and opulent appearance. Mirror finish steel sheets are commonly employed in decorative applications, including automotive trim, jewelry, and ornamental architectural elements. To summarize, the primary distinction between a satin and mirror finish steel sheet resides in their appearance and level of reflectivity. Satin finish offers a smooth, matte appearance with minimal reflectivity, while mirror finish provides an incredibly reflective, mirror-like surface.

- Q:Can steel sheets be used for fire-rated doors?

- Yes, steel sheets can be used for fire-rated doors. In fact, steel is one of the most commonly used materials for fire-rated doors due to its high strength, durability, and fire-resistance properties. Steel sheets used in fire-rated doors are typically constructed with multiple layers of fire-resistant material, such as gypsum or mineral core, sandwiched between the steel sheets. This construction helps to prevent the spread of fire and smoke, providing a reliable barrier in the event of a fire. Additionally, steel is known for its structural integrity, making it a suitable choice for fire-rated doors that need to withstand high temperatures and pressure.

- Q:What are the different alloys used in steel sheet production?

- There are several different alloys used in steel sheet production, including carbon steel, stainless steel, galvanized steel, and weathering steel.

- Q:Can steel sheets be used in corrosive environments?

- Corrosive environments necessitate careful consideration of the type of steel used and appropriate protective measures. Stainless steel, for instance, is known for its exceptional resistance to corrosion and ability to withstand harsh conditions. It contains chromium, which creates a protective oxide layer on the surface, preventing corrosion. Alternatively, galvanized steel involves applying a layer of zinc to the surface, forming a protective barrier against corrosion. Furthermore, one can enhance the resistance of steel sheets to corrosive elements by applying various coatings like epoxy, polyurethane, or paint. The selection of the right steel grade and protective coatings is crucial and should be based on the specific corrosive environment to ensure long-lasting performance. Regular inspections and maintenance are also imperative to promptly identify and address any potential signs of corrosion.

- Q:Can steel sheets be laminated with other materials?

- Indeed, it is possible to laminate steel sheets with different substances. Lamination involves the fusion of two or more materials to form a composite material that boasts improved characteristics. When it comes to steel sheets, they can be laminated with a variety of materials including plastics, polymers, wood, and even other metals. This technique is frequently employed to enhance the strength, longevity, resistance to corrosion, and visual appeal of steel sheets. Laminated steel sheets can be observed in numerous sectors such as automotive, construction, aerospace, and furniture production.

- Q:Are steel sheets suitable for medical equipment manufacturing?

- Indeed, steel sheets prove to be appropriate for the manufacture of medical equipment. Steel, being a versatile and long-lasting material, finds widespread usage in the production of medical devices. It presents numerous benefits including remarkable strength, resistance to corrosion, and the ability to be customized effortlessly. By molding, welding, and machining steel sheets, intricate shapes and structures essential for medical equipment can be effortlessly fashioned. Moreover, steel possesses hygienic properties that permit easy cleaning and sterilization, rendering it suitable for deployment in healthcare environments. On the whole, steel sheets are a dependable choice for the production of medical equipment owing to their robustness, durability, and ease of fabrication.

- Q:Can steel sheets be bent or shaped?

- Yes, steel sheets can be bent or shaped using various techniques such as rolling, pressing, or folding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized/Aluzinc Steel Sheet or Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords