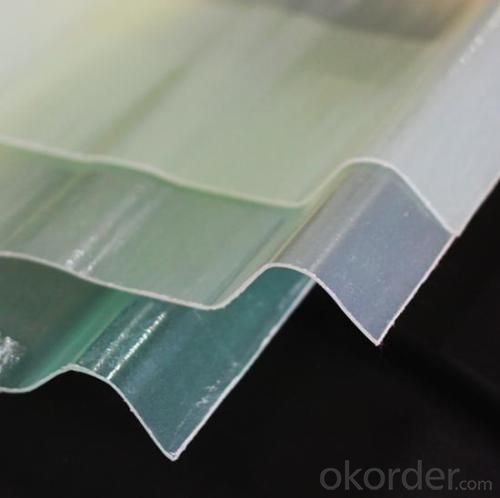

Frp Roofing Sheet Corrugated GRP Plastic Roofing with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q:Can FRP roofing panels be used in extreme weather conditions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in extreme weather conditions. FRP panels are known for their durability and resistance to various weather elements such as rain, snow, wind, and sunlight. They are designed to withstand harsh weather conditions, making them suitable for use in areas prone to extreme weather. FRP roofing panels are engineered to be highly resistant to corrosion, UV rays, and temperature changes. These panels are made from a combination of fiberglass and plastic materials, providing them with excellent strength and impact resistance. This makes them capable of withstanding strong winds, heavy snow loads, and hailstorms. Furthermore, FRP roofing panels have excellent thermal insulation properties, which help to regulate the temperature inside a building. This is particularly beneficial in extreme weather conditions, as it can help to keep the interior cool during hot summers and retain heat in colder climates. It is important to note that while FRP roofing panels are designed to withstand extreme weather conditions, proper installation, and regular maintenance are crucial to ensure their long-term performance. It is recommended to consult with a professional contractor or manufacturer for specific guidelines and recommendations based on the specific weather conditions in your area.

- Q:Can FRP roofing panels be walked on?

- To prevent damage, it is crucial to take certain precautions when walking on FRP (Fiberglass Reinforced Plastic) roofing panels. While these panels are designed to be sturdy and durable, cracking or breaking can occur due to excessive weight or improper handling. When walking on FRP roofing panels, it is essential to distribute your weight evenly by stepping on the supporting purlins or structural elements beneath the panels. Stepping directly on the unsupported areas should be avoided to minimize the risk of damage. Furthermore, wearing soft-soled shoes or boots is advisable to reduce the impact on the panels. It should be noted that FRP panels can become slippery in wet or debris-covered conditions, so extra caution should be exercised. Using safety equipment like harnesses or non-slip shoes can further enhance safety while walking on FRP roofing panels. Before attempting to walk on FRP roofing panels, it is recommended to refer to the manufacturer's guidelines or seek professional advice. This ensures that the specific type of FRP panel being used can withstand the intended weight and foot traffic. By following these precautions, the integrity of the panels can be maintained, and potential damage can be prevented.

- Q:Are FRP roofing panels available in different profiles?

- Yes, FRP roofing panels are available in different profiles.

- Q:Are FRP roofing panels resistant to bird nesting or damage?

- FRP roofing panels, also known as Fiberglass Reinforced Plastic panels, are generally resistant to bird nesting and damage. The smooth surface of FRP panels makes it difficult for birds to build nests as they cannot grip on to the material easily. Additionally, the durability and strength of FRP panels make it less prone to damage caused by birds. However, it is worth noting that no roofing material can be completely immune to bird activity. Persistent birds may still attempt to nest on FRP panels, especially in areas where they have easy access. In such cases, it is recommended to take preventive measures like installing bird deterrents or maintaining regular cleaning to discourage bird nesting.

- Q:How does FRP roofing panel differ from other roofing materials?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, differ from other roofing materials in several ways. Firstly, FRP panels are lightweight yet strong, making them easy to handle during installation and reducing the structural load on the building. Secondly, they have excellent resistance to chemicals, weathering, and UV exposure, ensuring long-term durability. Additionally, FRP panels are non-conductive and provide good thermal insulation, which can help regulate temperatures inside the building. Lastly, FRP panels are highly versatile and can be molded into various shapes, allowing for customizable designs and applications.

- Q:Can FRP roofing panels be used in coastal areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in coastal areas. FRP panels are known for their exceptional durability and resistance to harsh weather conditions, including exposure to saltwater and high humidity levels. These panels are non-corrosive and do not rust, making them an ideal choice for coastal regions where traditional roofing materials may deteriorate quickly due to the saltwater air and moisture. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, making them a practical and cost-effective option for roofing in coastal areas.

- Q:Can FRP roofing panels be used in indoor swimming pools?

- Indoor swimming pools can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, water resistance, and corrosion resistance, FRP panels prove to be an ideal selection for such pools. Moreover, these panels are lightweight, effortless to install, and possess exceptional thermal insulation qualities. Furthermore, FRP panels exhibit resistance towards the chemicals found in pool water, which have the potential to corrode numerous other construction materials. In summary, FRP roofing panels offer a dependable and pragmatic solution for indoor swimming pools.

- Q:Can FRP roofing panels be installed on curved or irregularly shaped roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on curved or irregularly shaped roofs. FRP panels are flexible and can be easily molded to fit the contours of a curved or irregular roof. This makes them a versatile option for various architectural designs and roof shapes.

- Q:Are FRP roofing panels resistant to impact damage?

- FRP roofing panels, known as Fiberglass Reinforced Panels, are generally highly resistant to impact damage. The inclusion of fiberglass reinforcement in FRP panels provides them with added strength and durability, making them less susceptible to damage from impacts in comparison to other roofing materials. Consequently, FRP panels are an excellent choice for regions that frequently experience severe weather conditions, such as hailstorms or falling debris. It is important to bear in mind, however, that while FRP panels possess resistance to impact damage, they are not entirely impervious. In instances where a heavy object falls directly on the panel or a considerable amount of force is applied, some damage may still occur. Consequently, it is highly recommended to perform regular maintenance and inspections to ensure the prolonged lifespan and optimal performance of FRP roofing panels.

- Q:Are FRP roofing panels resistant to termites or other pests?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to termites and other pests. The composition of FRP panels, which includes a layer of fiberglass reinforced with plastic resin, makes it difficult for pests to penetrate or damage the material. This resistance to termites and other pests is one of the advantages of using FRP roofing panels in construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frp Roofing Sheet Corrugated GRP Plastic Roofing with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords