FRP pultruded grating Resistance to weathering on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

FRP PULTRUDED GRATING AND PULTRUSION PROCESS

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

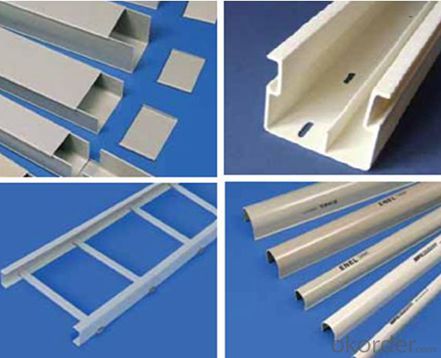

PICTURES

- Q:Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP pultrusion profiles can be used in the construction of industrial flooring. These profiles are lightweight, durable, and corrosion-resistant, making them an ideal choice for industrial applications. They offer high strength-to-weight ratio, excellent load-bearing capacity, and resistance to chemicals, moisture, and extreme temperatures. Additionally, FRP pultrusions can be customized to meet specific design requirements, making them versatile for various industrial flooring applications.

- Q:Are FRP pultrusion profiles resistant to alkaline substances?

- FRP pultrusion profiles are known for their general resistance to alkaline substances. By using fiberglass reinforced polymer (FRP) in pultruded profiles, they acquire excellent resistance against a wide range of chemicals, including alkaline substances. The manufacturing process typically involves using a thermosetting polymer, such as polyester or vinyl ester, as the resin. This choice of resin ensures high resistance to alkaline solutions. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them highly resistant to corrosion and degradation caused by alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the resin formulation and manufacturing process used. Therefore, it is advisable to consult the manufacturer or supplier to confirm that the profiles meet the specific resistance requirements for alkaline environments.

- Q:Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that render them suitable for this purpose. To begin with, FRP pultrusion profiles exhibit resistance to corrosion. Water treatment plants encounter various corrosive substances, such as chemicals and moisture. Traditional materials like steel and concrete can degrade over time due to corrosion, resulting in maintenance complications and potential structural failures. Nevertheless, FRP pultrusion profiles possess a high resistance to corrosion, ensuring prolonged durability and reduced maintenance expenses. Furthermore, FRP pultrusion profiles are lightweight and possess high strength-to-weight ratios. This characteristic facilitates easy handling and transportation while maintaining structural integrity. Water treatment plants often necessitate structural components that can endure heavy loads and support equipment. FRP pultrusion profiles supply the required strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and possess exceptional electrical insulation properties. This attribute proves critical in water treatment plants where electrical apparatus and wiring are present. The non-conductive nature of FRP aids in preventing electrical hazards and guarantees safe operation. Moreover, FRP pultrusion profiles can be customized to fulfill specific design requirements. They can be manufactured in various shapes and sizes, allowing for design and construction flexibility. This adaptability renders FRP pultrusion profiles appropriate for a wide array of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In conclusion, FRP pultrusion profiles represent an exceptional option for the construction of water treatment plants due to their corrosion resistance, lightweight yet robust nature, electrical insulation properties, and customization possibilities. They provide long-lasting durability, reduced maintenance costs, and enhanced safety, thereby constituting a reliable and efficient solution for this critical infrastructure.

- Q:Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q:Are FRP pultrusion profiles resistant to high-pressure water jets?

- FRP pultrusion profiles have a general resistance to high-pressure water jets. Their high strength-to-weight ratio, corrosion resistance, and durability make them suitable for applications involving water and harsh environments. The pultrusion manufacturing process ensures thorough resin impregnation of the fibers, resulting in a dense composite material. This density provides high resistance to water penetration, protecting the material from damage by high-pressure water jets. Additionally, FRP pultrusion profiles exhibit excellent chemical resistance, including resistance to water. This ensures that the profiles will not degrade when exposed to high-pressure water jets for extended periods. It is important to note that the specific resistance of FRP pultrusion profiles to high-pressure water jets may vary depending on the resin and fiber combination used. To obtain detailed information about the resistance of specific profiles in a given application, it is recommended to consult the manufacturer or supplier.

- Q:The manufacturing process of FRP products?

- Each technique has its own characteristics. Production enterprises determine the process method in the selection, according to the basic situation of the enterprise and the production of products, such as mass production and product quality requirements, as well as the technical basis for enterprise capital and production factors such as comprehensive consideration.

- Q:Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q:Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

- Q:Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

- Q:The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- Pultrusion production of polyurethane pultruded profiles can be used in the new type of polyurethane material, the product can completely replace the FRP pultruded profiles, including polyurethane doors and windows profiles, tray, line guide groove, groove, polyurethane polyurethane tube and other molding parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP pultruded grating Resistance to weathering on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords