FRP GRP Fiberglass Glassfiber Corrugated Roofing with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

>> Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance, no high-temperature softening, cold brittle phenomenon;

>> Low thermal conductivity & good insulation performance;

>> Non-toxic, non-asbestos, etc., in line with world health standards;

>> No moss & prevent microbial growth;

>> High impact and resistant to strong wind;

>> Safe and reliable, Not combustion-supporting in open fire;

>> Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

Material | FRP, ASA, PVC | ||

Thickness | 1.0mm - 3.0mm | ||

Color | Clear, milk white, blue, green, red | ||

Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

Shelf life | 15 years | ||

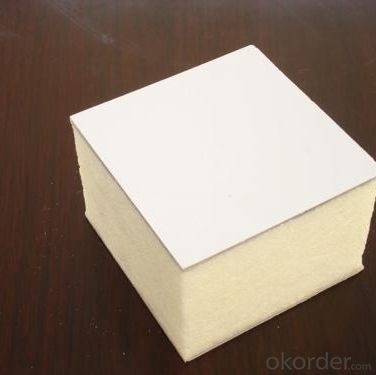

PICTURES

- Q:Are FRP roofing panels flexible?

- No, FRP roofing panels are not typically flexible. They are made from rigid fiberglass reinforced plastic materials that provide durability and structural integrity.

- Q:Can FRP roofing panels be used for both indoor and outdoor applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both indoor and outdoor applications. FRP roofing panels are versatile and durable, making them suitable for various environments. They are commonly used in industrial buildings, commercial establishments, residential structures, and agricultural facilities. Indoors, FRP roofing panels are often used in areas that require natural light but cannot accommodate windows, such as warehouses, manufacturing facilities, and storage rooms. They provide excellent light transmission, reducing the need for artificial lighting and lowering energy costs. Additionally, FRP panels are resistant to moisture, chemicals, and UV rays, making them ideal for applications in areas with high humidity or exposure to harsh substances. Outdoors, FRP roofing panels are commonly used in patio covers, pergolas, and other outdoor structures to provide shade and protection from the elements. They are lightweight yet strong, making installation easier and ensuring long-lasting performance. FRP panels are also resistant to weathering, so they can withstand exposure to rain, snow, sunlight, and extreme temperatures without deteriorating or losing their structural integrity. Overall, FRP roofing panels are a versatile and cost-effective solution for both indoor and outdoor applications. They offer a range of benefits, including durability, light transmission, resistance to moisture and chemicals, and ease of installation, making them suitable for a wide range of projects.

- Q:Do FRP roofing panels provide good insulation?

- Despite their durability, strength, and resistance to weather elements, FRP roofing panels, also known as Fiberglass Reinforced Plastic panels, do not offer sufficient insulation on their own. The insulation level primarily relies on the material and thickness of the panel. FRP panels are typically thin and are primarily designed for protecting and strengthening the roofing structure rather than providing thermal insulation. To address insulation concerns, it is recommended to consider incorporating additional measures such as insulation boards, foam panels, or other thermal insulating materials in combination with FRP panels. This approach will improve the overall insulation performance of the roofing system, resulting in better temperature control and enhanced energy efficiency.

- Q:Are FRP roofing panels suitable for flat roofs?

- FRP roofing panels are indeed appropriate for flat roofs. Their lightweight nature, durability, and superb resistance against UV rays, weathering, and corrosion make them an optimal choice. Moreover, their high strength-to-weight ratio renders them ideal for flat roofs where weight is a potential issue. Furthermore, FRP panels possess commendable thermal insulation characteristics, effectively regulating temperature and reducing energy consumption. Additionally, they are effortlessly installed and maintained, establishing them as a cost-efficient option for flat roof applications.

- Q:Are FRP roofing panels resistant to damage from falling objects?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to damage from falling objects. The strong and durable nature of FRP materials allows them to withstand impact and provide a protective barrier against potential damage. However, the extent of resistance may vary depending on the specific thickness and quality of the FRP panels. It is always recommended to consult with manufacturers or experts to determine the suitability of FRP roofing panels for specific applications where falling objects may be a concern.

- Q:Can FRP roofing panels be used for agricultural buildings?

- Agricultural buildings can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. The agricultural industry often favors FRP panels due to their durability, cost-effectiveness, and versatility. The strength-to-weight ratio of FRP roofing panels is well-known, as they are both lightweight and incredibly strong. This quality makes them applicable to a wide range of agricultural purposes, such as barns, livestock shelters, poultry houses, and storage facilities. In addition, FRP panels exhibit resistance to various environmental factors commonly found in agricultural settings. They are highly resistant to corrosion, UV rays, chemicals, and moisture, enabling them to endure severe weather conditions and the corrosive effects of animal waste and fertilizers. Furthermore, FRP roofing panels provide excellent insulation properties, creating a more comfortable environment for livestock and ensuring optimal temperature control within agricultural buildings. Additionally, they possess good light transmission properties, allowing natural daylight to penetrate the building and reducing the need for artificial lighting during the day. Moreover, the installation and maintenance of FRP panels are relatively straightforward. They are available in various sizes and can be easily tailored to fit the specific dimensions of the agricultural structure. The lightweight nature of FRP panels often leads to quicker installation and lower structural support requirements compared to alternative roofing materials. Regular cleaning to remove dirt and debris is generally the only maintenance needed to uphold the longevity and performance of the panels. Overall, FRP roofing panels serve as a dependable and practical option for agricultural buildings. Their durability, cost-effectiveness, and ability to withstand harsh environmental conditions make them a suitable roofing choice for farmers and agricultural businesses.

- Q:Can FRP roofing panels be installed in high-wind areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed in high-wind areas. FRP panels are known for their durability and strength, making them suitable for withstanding strong winds. However, it is important to ensure proper installation techniques are followed to maximize their resistance to high winds. This may include using appropriate fasteners and sealants, following manufacturer's guidelines, and considering wind uplift forces in the design. Additionally, it is advisable to consult local building codes and regulations to ensure compliance with specific wind load requirements in high-wind areas.

- Q:Are FRP roofing panels suitable for areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for areas with heavy snowfall. FRP panels are known for their high strength and durability, making them capable of withstanding the weight and pressure of snow accumulation. Additionally, FRP panels have excellent thermal insulation properties, which can help prevent snow from melting and refreezing, reducing the risk of ice dam formation. However, it is essential to ensure proper installation and reinforcement to handle the specific snow load requirements of the area.

- Q:Do FRP roofing panels require any specific tools for installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require specific tools for installation. Some common tools that may be needed include a power drill with appropriate drill bits, a saw for cutting the panels to size, a tape measure, a level for ensuring proper alignment, a caulking gun for applying sealant, screws or nails for securing the panels in place, and a ladder or scaffolding for accessing the roof. It is important to use the correct tools to ensure a proper and secure installation of FRP roofing panels.

- Q:Do FRP roofing panels have any special fire rating certifications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can have special fire rating certifications. The fire rating of FRP roofing panels is determined by various factors such as the type of resin used, the thickness of the panel, and the presence of fire-retardant additives. To ensure the safety and compliance of FRP roofing panels, they undergo rigorous testing and evaluation to obtain fire rating certifications. The most common fire ratings for FRP panels include Class A, Class B, and Class C. Class A fire-rated FRP panels are the most fire-resistant and have the highest level of protection. They are designed to resist severe fire exposure and have low flame spread and smoke development. These panels are typically used in applications where fire safety is of utmost importance, such as commercial buildings, hospitals, and schools. Class B fire-rated FRP panels offer moderate fire resistance and are suitable for applications where a higher level of fire protection is required but not as critical as Class A. They have a moderate flame spread and smoke development rate. Class C fire-rated FRP panels provide the lowest level of fire resistance. While they still offer some level of protection, they are not suitable for applications where fire safety is a top concern. These panels have a higher flame spread and smoke development rate compared to Class A and B. It is essential to check the fire rating certifications of FRP roofing panels before selecting them for a specific application. These certifications ensure that the panels meet the required fire safety standards and provide adequate protection against fire hazards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP GRP Fiberglass Glassfiber Corrugated Roofing with High Quality On Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords