FM Rubber Plastic Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

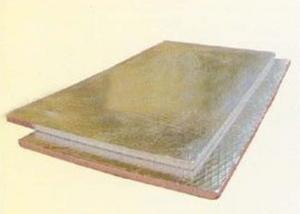

3.Rubber Plastic Images

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. Sandwich panels are made of two layers of rigid material with a core material in between. The rigid layers provide strength and durability, while the core material provides insulation and soundproofing properties. In a retail outlet, sandwich panels can be used for various purposes. They can be used as exterior cladding for the building, providing a sleek and modern look. The panels can also be used for interior walls and partitions, creating separate spaces within the store. Sandwich panels are easy to install and can be customized to fit the specific requirements of the retail outlet. They can be painted or decorated to match the branding and aesthetics of the store. Additionally, sandwich panels are lightweight and can be easily transported and assembled, making them a cost-effective choice for retail outlets. Furthermore, sandwich panels offer excellent thermal insulation, helping to keep the store cool in summer and warm in winter. This can lead to energy savings and a comfortable shopping environment for customers. Overall, sandwich panels are a suitable choice for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an attractive and functional solution for both the exterior and interior of the store.

- Q:What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q:Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Copper contains rubber and plastic. PEF and glass wool are both suitable, but glass wool is not recommend for its poor waterproofing performance, you'd better use rubber and plastic! You can select them with appropriate thickness according to your local winter temperature, or else it will be frozen in winter for it is too thin.

- Q:Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is the external wall insulation, silicate Lu power plant with more

- Q:Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q:What's the difference between rock wool board, glass wool board, glass wool felt?

- 1, The main difference between rock wool and glass wool lies in withstanding temperature. Rock wool can withstand 650 degrees, but glass wool can withstand 300 degrees. Rock wool board can be used for building external wall thermal insulation, large petrifaction pipelines or tank thermal insulation, etc. Glass wool board is used for tanks at room temperature and piping insulation. Glass wool felt is used in middle of double steel roof. 2, Products in Hebei are mineral wool which is poor and not suitable for exporting, or you will lose worsely. 3,All are fireproof. 4, These materials are fiber products which are water funk. Add water repellent to form waterproof membrane on the fiber surface. Fiber can only absorb no water. It is impossible for fiber to be waterproof as it has many gaps. 5, Aluminum foil can be attached. Glass wool felt can be to be vacuumized to reduce the package volume and transportation cost.

- Q:I am specifically considering the re-roofing of a an older home where rafters were made with 2x4 or 2x6 and the rafter space (and possibly the attic space) does not allow sufficient space for insulation and proper ventilation behind the insulation. The old layers of roofing have to be removed in any event. At this point I am considering applying insulation boards on the existing sheathing and then a new layer of sheathing before the new roofing material. (similar to a SIP: structural insulated panel) The two issues I am concerned with is that the insulation can act as a vapor barrier. Would condensation potentially rot the lower sheathing. How is this avoided in SIP roofing panels? The second issue may be with fire regulations.

- The sip panels are vented depending on what thickness over all that you want. The last ones I used had 4 inches of rigid foam board then on top of that had 3" strips every 16" an inch thick which created an airspace. On top was 5/8 Osb. To create an affective air flow the fascia cannot plane through with the plywood at the bottom but fall just short of the 1" space. To cap it a oversized vented drip edge is used. You must also have a ridge vent for proper flow. These panels can near 100$. You can do it your own way like I do when building log cabins by laying 2" foam down first then lay 2x4 16 on center on top then finally your plywood. If you use CDX instead of Osb it will outlast it by 100%. Rigid foam insulation is not like batt-faced. Rfboard ins. Is used in boat hulls and even after being submerged for long periods of time will return to its original density and r-value. For obvious reasons batt ins. Will not. You won't have a moisture problem as long as you don't have a venting problem. If you are using high hat lighting don't let the cans touch your rigid ins. Tuck batt in softly around them TAKE THE PAPER OFF! By code if you have an interior wall 10or more ft. It must have a fireblock, simply a 2x4 turned flat between the studs. On your roof the ceiling you see inside, (most likely 7/8 tongue and groove boards) passes as the same. Good luck!

- Q:What does the thermal insulation test of glass rock wool include?

- Appearance, dimensional deviation(length, width, height), shot content, average diameter of fibers, flatness deviation, right-angle deviation, water absorption coefficient, hydrophobic rate, short-term water absorption, tensile strength perpendicular to the surface, compression strength, heat conductivity coefficient, dimensional stability, noise reduction coefficient, acidity coefficient, vapor diffusion resistance factor, long-term water absorption, combustion performance. These are testing programs of rock wool thermal insulation boards. The raw materials and performance of which are different from that of glass wool. In addition to the different areas, the required testing programs are different too. My answer is for reference only.

- Q:What is the difference between quartz wool and glass wool?

- Glass wool is categorized into glass fiber, which is a manmade inorganic fiber. Glass wool employs quartz sand, limestone, dolomite and other natural ores as the main raw materials, accompanying with some soda ash, boraxes and other chemicals to melt into glass. In the molten state, cotton-shaped thin fiber can be made by means of blowing force, and fibers and fibers will be vertically crossed and intertwined with each other.

- Q:The main classification and difference of glass wool

- Centrifugal glass wool is the glass as the main raw material and then in accordance with a certain proportion with a variety of other materials mixed into the glass melting furnace after the full melting, the solution will melt a good solution through the leakage into the centrifuge

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FM Rubber Plastic Sheet and Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords