Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

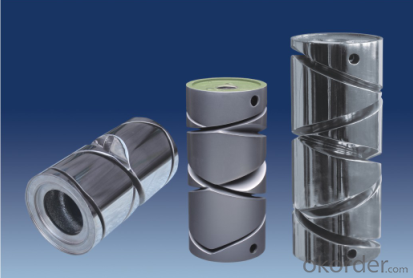

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

Adavantages:

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Models of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts:

· Q:What is the machine used for?

A:Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q:When the textile industry, as well as the history of the textile industry development?

- Chinese machine textile originated in five thousand years ago Neolithic spinning wheel and waist machine. Western Zhou Dynasty with the traditional performance of the simple mechanical reeling car, spinning, looms have emerged, the Han Dynasty widely used jacquard machine, oblique loom, after the Tang Chinese textile machinery is maturing, greatly promoted the development of the textile industry.

- Q:The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- State textile machinery industry after decades of development, has made great progress. But compared with the world's advanced technology, there are still some gaps and some more serious problems. The overall technical level of textile machinery is low, product independent development and innovation ability is weak, lack of research and development funds. Enterprise technical reform is not enough, manufacturing technology behind

- Q:China's textile industry prospects of printing and dyeing ?

- Prospective Industry Research Institute released the "China Textile Machinery Manufacturing Industry demand and investment forecast analysis report" shows that China's textile machinery manufacturing industry in recent years to maintain rapid development momentum.

- Q:What is a spinning wheel?

- Ancient general spinning machine according to the structure can be divided into hand-spinning and pedal spinning two.

- Q:What is the history of the development of textile machinery?

- Human beings originally used natural fibers as raw materials for spinning and weaving, earlier than the invention of the text (see World Textile History, China Textile History).

- Q:How does the mechanical wave generated in the spinning process work?

- Mechanical waves meet, you can cross each other, do not interfere with each other

- Q:What is the cashmere dyeing process?

- Spinning the best equipment is the Italian equipment, and now a lot of small manufacturers useful in Japan, there are some domestic modified, the Italian equipment of each of more than 1200 million RMB

- Q:What are the risks of safety accidents in the textile machinery industry?

- The Fourth, in the exposed parts of the drive did not take security measures.

- Q:What is the current status of the textile industry?

- China's textile enterprises should overcome the difficulties of rising raw materials, appreciation of the renminbi and export tax rebates, seize the opportunities for the development of the textile industry, improve the concentration of the industry, curb the blind expansion of inefficient production capacity, increase the construction of special industrial parks, strengthen independent innovation The pace of China's textile industry to enhance the brand building, industrial restructuring and upgrading. So that China by the textile power to the textile power forward.

- Q:What is the difference between yarn spinning and ring spinning?

- Ring spinning (combing) Process: clear flowers - carding - pre-parallel - articles and rolls - combing - the first road parallel - two parallel - roving - spinning - Winding

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flinty Aluminum Alloy Grooved Drumof Textile Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords