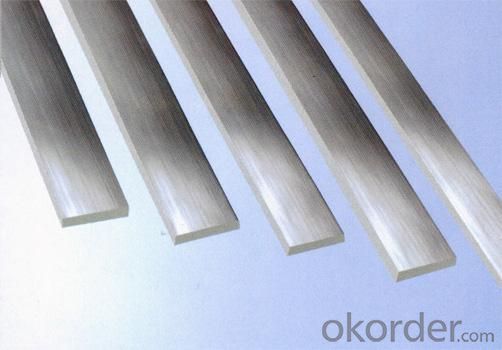

Flat Bar Hot Rolled High Quality GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Commodity: Mild Steel Flat Bar Standard: GB;JIS Material: Q195-235;SS400 Brand name: FLATSPACE Origin place: China Thickness: 3mm-30mm Width:20mm-200mm Length: Max 12m Certification: SGS/BV Chemical composition of Q235

Physical properties of Q235

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q:What is the negative deviation allowed by the national standard for galvanized flat steel of 40*4?

- 40*4 galvanized flat steel GB permitted negative deviation value is the thickness deviation value is 0.2mm, the deviation 0.4mm, the width deviation value is the upper deviation 0.5mm, lower deviation 1.0mm

- Q:Can steel flat bars be used for fencing or gates?

- Certainly! Fencing or gating purposes can indeed make use of steel flat bars. These bars possess qualities such as strength, durability, and resistance to corrosion, rendering them ideal for outdoor applications. By welding or bolting them together, a robust fence or gate structure can be formed. Moreover, steel flat bars can be conveniently tailored and molded to meet specific design specifications. Irrespective of whether it is intended for residential, commercial, or industrial usage, steel flat bars offer a dependable and enduring solution for fencing or gating requirements.

- Q:How do steel flat bars compare to copper flat bars?

- Steel flat bars are generally stronger and more durable than copper flat bars. Steel has a higher tensile strength and is less prone to bending or warping under heavy loads. Additionally, steel is more resistant to corrosion and can withstand harsh environmental conditions better than copper. However, copper flat bars have superior electrical conductivity and are often preferred for electrical and plumbing applications. Ultimately, the choice between steel and copper flat bars depends on the specific requirements and intended use of the material.

- Q:What are the different methods of cutting steel flat bars?

- Steel flat bars can be cut using various methods, each with unique benefits and applications. 1. Sawing: Sawing with different types of saws, such as band saws, circular saws, and abrasive saws, is a commonly used method. Band saws are efficient for cutting large quantities of steel bars, while circular saws are suitable for smaller jobs or thicker bars. Abrasive saws, also known as cutoff saws, employ a rotating abrasive disc to cut through the steel. 2. Shearing: Shearing involves the use of a shear machine that exerts significant force to cut through the material. This method is particularly effective for cutting thick steel bars, resulting in clean and straight cuts. 3. Plasma cutting: This advanced method employs a high-velocity jet of ionized gas to melt and cut through the steel. It offers precise cutting, enabling the creation of intricate shapes and designs, making it ideal for complex cutting requirements. 4. Laser cutting: Similar to plasma cutting, laser cutting utilizes a high-powered laser beam to melt and cut through the steel. This technique provides exceptional accuracy and produces clean and smooth cuts. Laser cutting is often preferred for thin steel flat bars or for precise and intricate designs. 5. Waterjet cutting: Waterjet cutting involves a high-pressure jet of water mixed with abrasive particles to cut through the steel. This versatile method can be used on various materials, including steel. It is especially useful for thicker steel bars or materials sensitive to heat. Ultimately, the choice of cutting method depends on factors such as steel thickness, desired precision, and design complexity. Considering these factors is crucial when selecting the appropriate cutting method for steel flat bars.

- Q:Can steel flat bars be used in the manufacturing of conveyor systems?

- Yes, steel flat bars can be used in the manufacturing of conveyor systems. Steel flat bars are commonly used as support structures or frame components in conveyor systems due to their strength, durability, and versatility. They can be easily welded or bolted together to create custom-sized frames or supports that can withstand heavy loads and continuous use. Additionally, steel flat bars can be shaped or cut to fit specific conveyor designs, making them an ideal choice for conveyor system manufacturing.

- Q:Can steel flat bars be used for making tools or toolboxes?

- Yes, steel flat bars can be used for making tools or toolboxes. Steel is a strong and durable material, making it suitable for constructing various tools and toolboxes that require strength and stability. Additionally, steel can be easily shaped and welded, allowing for the creation of customized tool designs.

- Q:Can steel flat bars be used for manufacturing handrails or balustrades?

- Yes, steel flat bars can be used for manufacturing handrails or balustrades. They are commonly used due to their strength, durability, and versatility in design.

- Q:How do you cut a steel flat bar?

- To cut a steel flat bar, you will need the following tools: a metal cutting saw, a clamp or vice to secure the bar, and safety equipment such as gloves and goggles. Here's a step-by-step guide on how to cut a steel flat bar: 1. Measure and mark the desired length of the steel flat bar using a measuring tape and a marker. Make sure the marks are clearly visible. 2. Secure the steel flat bar in a clamp or vice, ensuring that it is tightly held and won't move during the cutting process. This will provide stability and prevent any accidental movements. 3. Put on safety gloves and goggles to protect yourself from any flying metal fragments or sparks. 4. Position the metal cutting saw perpendicular to the steel flat bar, aligning it with the marked cutting line. 5. Start the saw and slowly guide the blade into the steel flat bar, applying steady and even pressure. Let the saw do the cutting work; avoid forcing or pushing too hard, as this can damage the saw blade or cause the steel to overheat. 6. Continue cutting until you reach the marked cutting line. Take breaks periodically to allow the steel to cool down if needed, as excessive heat can affect the cutting process. 7. Once the cut is complete, turn off the saw and inspect the steel flat bar for any rough edges or burrs. Use a metal file or sandpaper to smooth out any imperfections. 8. Finally, remove the steel flat bar from the clamp or vice and clean up the work area, ensuring all metal shavings are properly disposed of. Remember to exercise caution and follow proper safety protocols when cutting steel, as it can be sharp and produce sparks. If you are unsure or lack experience, it is advisable to seek assistance from a professional or consult a metalworking specialist.

- Q:Can steel flat bars be used for making railway industry equipment or structures?

- Yes, steel flat bars can be used for making railway industry equipment or structures. Steel flat bars are commonly used in the railway industry due to their strength, durability, and versatility. They can be easily fabricated and shaped to meet the specific requirements of railway equipment and structures such as tracks, railings, bridges, and platforms. Additionally, steel flat bars are highly resistant to wear, corrosion, and extreme weather conditions, making them ideal for use in the railway industry where safety and longevity are crucial.

- Q:What are the different methods of surface sanding for steel flat bars?

- There are several different methods of surface sanding for steel flat bars. The choice of method depends on the desired finish and the specific requirements of the project. 1. Hand Sanding: This method involves using sandpaper or sanding blocks to manually sand the surface of the steel flat bars. It is a simple and cost-effective method, but it can be time-consuming and may not provide a uniform finish. 2. Belt Sanding: Belt sanding machines use abrasive belts to remove material from the surface of the steel flat bars. They are efficient and can achieve a consistent finish. Belt sanding machines come in different sizes and with various grit options, allowing for customization based on the desired outcome. 3. Disc Sanding: Disc sanding machines utilize rotating sanding discs to remove material from the surface of the steel flat bars. They can be used for heavy material removal or fine finishing, depending on the grit of the sanding discs. Disc sanding machines are available in different sizes and configurations to suit different needs. 4. Random Orbital Sanding: This method involves using a random orbital sander, which combines the spinning action of a disc sander with the random orbit motion of an orbital sander. The sanding discs used with this machine have a random pattern, which helps prevent swirl marks on the surface of the steel flat bars. Random orbital sanders are versatile and can be used for both material removal and fine finishing. 5. Vibratory Sanding: Vibratory sanding machines use vibration to remove material from the surface of the steel flat bars. They are often used for deburring, as well as for achieving a smooth finish. Vibratory sanding machines come in various sizes and can be equipped with different types of media, such as ceramic stones or plastic pellets, depending on the desired outcome. 6. Grinding: Grinding is a more aggressive method of surface sanding that uses a grinding wheel or disc to remove material from the steel flat bars. It is commonly used for heavy material removal, such as removing welds or shaping the steel flat bars. Grinding can be done manually or with the use of grinding machines, depending on the size and complexity of the project. Each method of surface sanding for steel flat bars has its advantages and limitations. The choice of method should be based on factors such as the desired finish, the amount of material to be removed, and the resources available. It is important to consider safety precautions and wear appropriate protective equipment, such as goggles and gloves, when using any of these methods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar Hot Rolled High Quality GB Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords