film faced plywood High quality First-Class a

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

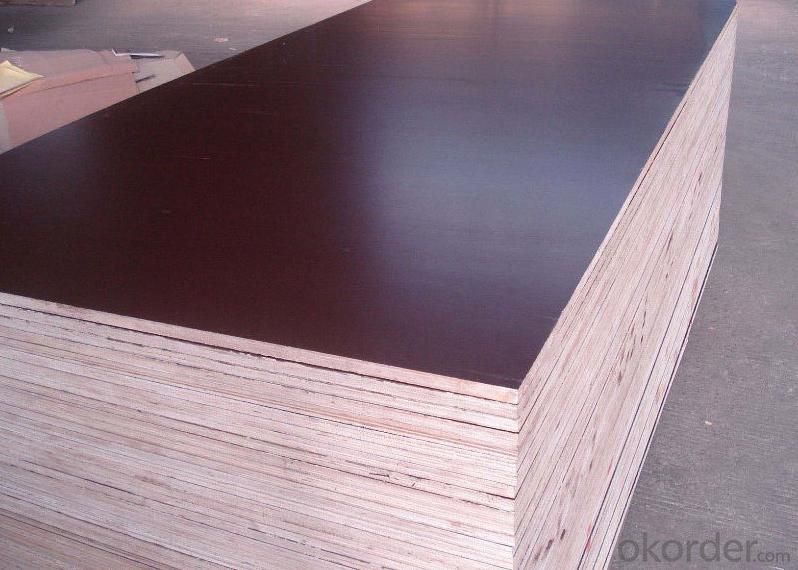

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

Features

1. Excellent performance of flame retardant;

2. High chemical stability and Anti-aging;

3. Excellent performance of bonding, coating and machining;

4. Mechanical properties meet the requirements of first-class product to national standard;

5. Non-toxic, non-polluting;

6. Non-corrosive metal;

7. Improved performance of Anti-Mildew;

8. Free formaldehyde content superior to class E1 of GB;

9. Low smoking and the high level of safety.

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

Packaging & Delivery

Packaging Details: export standard packing,inside covered with plastic bag, outside covered with carton then steel strip for strength, the bottom with regenerative wood pallet

Delivery Detail: 15days after received 30%TT as deposit

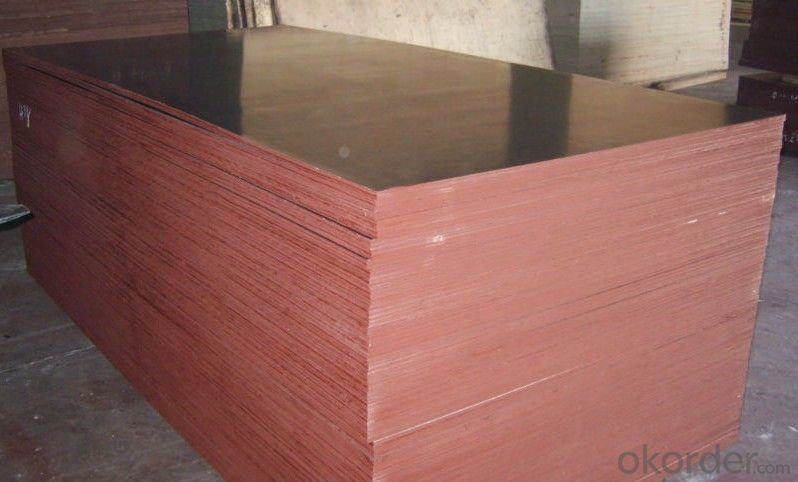

commercial plywood

Specifications

1.commodity:commercial plywood.

2.size: 1220x2440mm, 915x2135mm.

3.thickness: 1.7-30mm.

4.glue: MR, E2, E1, E0, MEL, WBP.

Good quality commercial plywood for furniture use

Specifications

1.size:1220*2440*1.7-35mm

2.surface:veneer,PVC,PU,UV,Melamine paper

3.material:poplar hardwood combi

4.usage:furniture,packing,construction

Good quality Commercial Plywood

Conventional data: | Size: | 1220mm*2440mm&1250mm*2500mm or as your demand | ||

1/8inch(2.7-3.6mm) | 3mm = 112sheets/cbm | |||

1/4inch(6-6.5mm) | 6mm = 56sheets/cbm | |||

Thickness: | 3/8inch(8.5-10.2mm) | 9mm = 37.33sheets/cbm | ||

(2.0—30mm) | 1/2inch(12-12.7mm) | 12mm = 28sheets/cbm | ||

5/8inch(15-16mm) | 15mm = 22.4sheets/cbm | |||

3/4inch(18-19mm) | 18mm = 18.66sheets/cbm | |||

Core: | poplar,hardwood,combi core etc | |||

Glue: | E0 , E1,E2,MR,WBP, MELAMINE | |||

Face/back: | okoume,bintangor,keruinging,poplar,pine,melamine paper etc | |||

thickness of faced: >= 0.45mm | ||||

Grade: | AAA first class | |||

Moisture: | <12% | |||

Thickness tolerance: | (+/-)0.5mm | equal to and more than 12mm | ||

(+/-)0.3mm | less than 12mm | |||

Physical parameters: | density:>520—650G/cbm | |||

modulus of rupture: > 30Mpa | ||||

modulus of elasticity :>6000Mpa | ||||

Standards: | Plywood grading standard for USA order | |||

Export standard packing: | inner | pallet lined with 0.2mm plastic bag | ||

Outer | outside covered with carton then steel strip for strength, the bottom with regenerative wood pallet | |||

Quantity: | 20'GP | 8 Crates/12000kgs/21.43cbm | ||

40'GP | 16 Crates/24000kgs/42.87cbm | |||

40'HQ | 18-19 Crates/28500kgs/48.23cbm | |||

Delivery time: | 15 days after order confirmed | |||

Term of payment: | L/C at sight, T/T | |||

Capacity: | 5000 Cubic Meter / Month | |||

Certificate | CE,CARB,FSC,ISO9001,ISO14001 | |||

- Q:Further processing of the plywood

- Anticorrosion plywood preserving treated plywood Plywood for use with potent or insecticide.

- Q:What are the types of veneer veneer veneer?

- according to the decorative veneer texture can be divided into radial decorative veneer veneer plywood chord decorative veneer veneer plywood

- Q:The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q:What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q:What types of plywood can be divided into?

- Plywood with durable, resistant to boiling or steam treatment and other properties, can be used in the outdoors.

- Q:What is the general use of plywood in decoration works?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q:The Preparation of plywood ingredients

- veneer veneer mountain peeling, semi-circular peeling, slicing or sawing the production of flakes of wood.

- Q:What are the advantages and disadvantages of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q:What is the type of plywood editing?

- decorative plywood (for construction, furniture, vehicles and ship decoration materials), the general use of plywood (for packaging, bedding and other uses)

- Q:Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

film faced plywood High quality First-Class a

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords