Fiberglass Geogrid Plastic Geogrid for Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

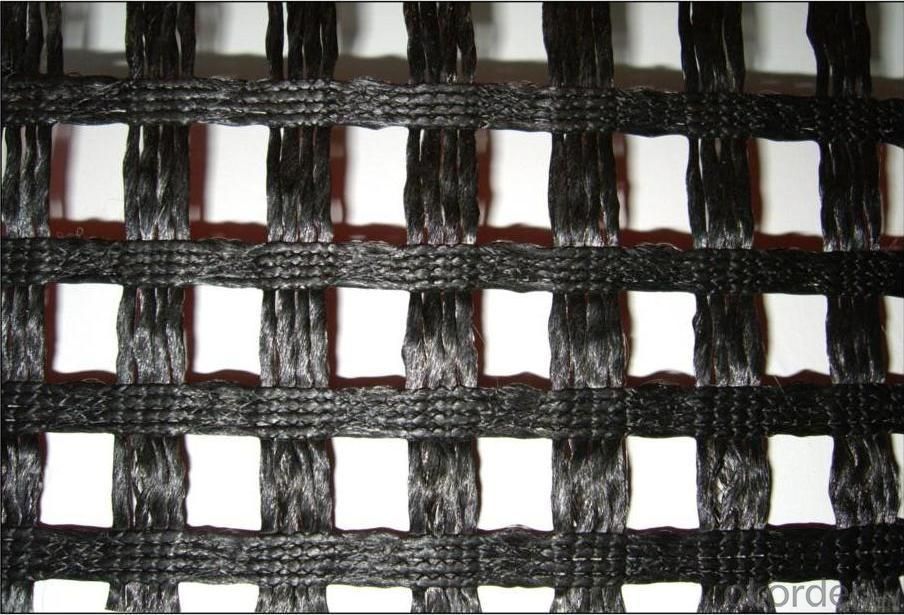

Structure of Fiberglass Geogrid description :

Made of GE fiber by weaving technology and coating treatment, it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Fiberglass Geogrid for coal mine:

High strength ,low elongation, heat resisitant, high modulus ,light weight, good flexibility,anti-erosion,

Application of of Fiberglass Geogrid for coal mine :

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Fiberglass Geogrid for coal mine

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Fiberglass Geogrid for coal mine Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Fiberglass Geogrid for coal mine : within 10 days after receiving the deposit

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

- Q:Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q:What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 3: waterproof gypsum board ????Waterproof gypsum board is in the gypsum core by adding a certain amount of waterproof plastic made of products, so waterproof gypsum board has a certain waterproof function, while gypsum board paper is also a waterproof measures, is a more widely used materials. Waterproof gypsum board with the effect of thermal insulation, but also has the advantages of fire, noise, but also an easy decoration materials. There is also a feature of the characteristics of environmental protection, due to the use of natural gypsum as a raw material, in the home environmental protection is guaranteed.

- Q:Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q:What are the key points and contents of the quality control of waterproof material?

- 1, polymer cement waterproof coating: it consists of a variety of water-based polymer emulsion and a variety of additives mixed with high-quality cement powder composition. Because of its high cost of polymer emulsion components (about 19,000 yuan / T), and the low cost of powder (about 800 yuan / T), it is because the liquid material, powder huge spread, the vast majority of fraud is to use 801 Glue + fossil powder + green dyestuff + cement blending; the other is to change the liquid material, the proportion of powder will be your liquid material consumption, as much as possible to increase the amount of powder. Resulting in poor waterproof coating adhesion, intolerance, after the completion of the finished product should not be too hard to pull down by hand, and was not much ductility of the sheet or even hand rub a few times into a powder, with blisters Will break down into small pieces. Can also be used to cut the finished product coating and then placed in the refrigerator freezer room after 8 hours to remove, gently forced to break will be broken, and the national standard requirements of the material to achieve low temperature flexibility -10 ℃.

- Q:Hello, roof with SBS waterproof material bulk density is how much?

- Similar to styrene-butadiene rubber, SBS can be in contact with water, weak acid, alkali, etc., with excellent tensile strength, surface friction coefficient, low temperature performance, excellent electrical properties, good processing properties, as the current consumption of the largest thermoplastic Elastomer.

- Q:What decoration materials, light and water, and the wall, the perfect combination of glass

- Between the glass and the wall is generally waterproof with waterproof glue, the specific steps are as follows: First, clean the surface Remove the surface of the joints of water, grease, dust and other pollutants, with a clean cloth to clean all the residue, so that the surface clean and dry. (If it is waterproof glue, the surface should be flat and clean, plastic gap to slightly curved as well.)

- Q:Developers have done waterproof, decoration house also have to do it

- Carbine water to remind you: the general finished house really done by the construction unit waterproofing, but we must know: First of all, developers for the rough housing waterproofing is more casual, may use the poor waterproof performance of the material, in the construction

- Q:Js waterproof coating without powder can brushing

- impossible. JS waterproof coating must be added cement, because this waterproof coating with a certain proportion of cement. 1. JS plastic waterproof coating before the construction of the base surface treatment: the base must be strong, clean, smooth, moist; base surface pores, cracks and other shortcomings, first to use cement mortar to achieve the role of repair smooth; Angle to use the knife to use this tool to repair the shape of the semi-fillet; to ensure that the base surface is full of moisture, but no water;

- Q:FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q:Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Plastic Geogrid for Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords