Fiberglass Geogrid Low Elongation Polyethylene Prices in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

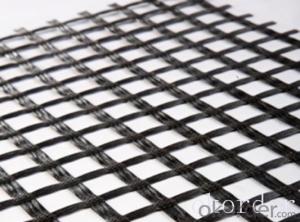

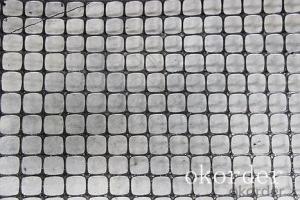

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q:How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by providing a strong and stable foundation. They act as a barrier between the soil and the wall, preventing erosion and soil movement. The geotextiles distribute the pressure from the soil evenly, increasing the stability and strength of the retaining wall. Additionally, they allow for proper drainage and filtration, reducing the build-up of water pressure behind the wall, which can cause structural failure.

- Q:How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement, filtration, and separation. They prevent the intermixing of different soil layers by acting as a barrier, thus enhancing the stability and reducing the settlement of the embankment. Additionally, geotextiles allow for the efficient drainage of water, preventing the buildup of excess pore pressure that could potentially lead to embankment failure.

- Q:What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide a wide range of functions in different construction and engineering applications. These functions include soil stabilization, erosion control, filtration, drainage, separation, and reinforcement. Geotextiles act as a protective barrier, improving the performance and lifespan of infrastructure projects such as roads, embankments, retaining walls, and landfills.

- Q:How do geotextiles improve the stability of slopes?

- Geotextiles improve the stability of slopes by providing reinforcement and erosion control. They are placed within the slope to enhance its strength, prevent soil erosion, and increase overall stability. The geotextiles act as a barrier, distributing the forces exerted on the slope and reducing the potential for sliding or failure. Additionally, they can promote water drainage, preventing the accumulation of excess water that may weaken the slope. Overall, geotextiles play a crucial role in enhancing the stability and longevity of slopes.

- Q:How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing erosion control, reinforcement, and drainage. They act as a barrier to prevent soil erosion, retain soil particles, and allow water to drain through the fabric, reducing the buildup of excess water pressure. Additionally, geotextiles enhance the stability and strength of slopes by distributing loads and limiting soil movement, thus preventing landslides and slope failures.

- Q:How do geotextiles affect soil consolidation?

- Geotextiles have a positive impact on soil consolidation as they provide reinforcement and stabilization. By acting as a barrier, they prevent the mixing of different soil layers, reducing the potential for settlement and increasing the overall strength of the soil. This consolidation is achieved through the interlocking of geotextile fibers with the soil particles, enhancing the load-bearing capacity and preventing the loss of fine particles.

- Q:What are the benefits of using geotextiles in construction projects?

- Geotextiles offer numerous benefits in construction projects. Firstly, they provide effective soil stabilization by preventing erosion, reducing sedimentation, and enhancing soil strength. Secondly, they act as a barrier against weed growth, enhancing the aesthetics and longevity of the project. Additionally, geotextiles facilitate efficient drainage, preventing water accumulation and potential damage to structures. They also aid in separation and filtration, preventing the mixing of different materials and promoting the flow of water. Furthermore, geotextiles are cost-effective and easy to install, saving both time and labor. Overall, the use of geotextiles in construction projects improves durability, reduces maintenance needs, and ensures long-term sustainability.

- Q:Can geotextiles be used in underground construction applications?

- Yes, geotextiles can be used in underground construction applications. Geotextiles are commonly used in underground construction for various purposes such as soil stabilization, drainage, filtration, and erosion control. They help to improve the overall performance and longevity of underground structures by providing reinforcement and preventing the migration of fine particles.

- Q:How do geotextiles affect soil properties?

- Geotextiles can have a positive impact on soil properties by improving its stability, filtration, and drainage capabilities. These synthetic fabrics act as a barrier, preventing soil erosion and promoting soil compaction. Additionally, geotextiles can enhance the soil's ability to retain water, aiding in irrigation and reducing the risk of drought.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Low Elongation Polyethylene Prices in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords