Fiberglass FRP Phenolic Molded and Pultruded Grating with Great Shape/Best Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

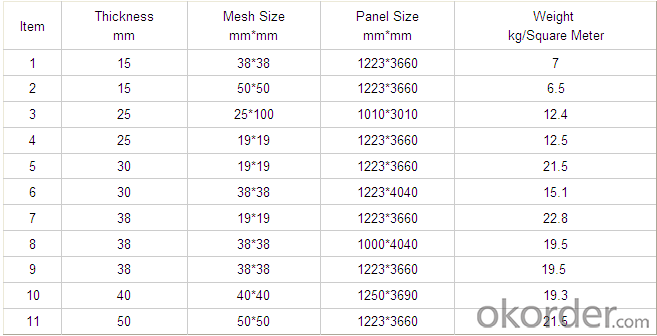

Specification

Advantage

1) coated with prevent aging layer

2) high strength

3) long service life

4) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q:What is the fatigue resistance of FRP pultrusion profiles?

- The fatigue resistance of FRP pultrusion profiles refers to their ability to withstand repeated or cyclic loading without experiencing failure or degradation over time. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their exceptional fatigue resistance compared to other traditional materials such as steel or aluminum. The fatigue resistance of FRP pultrusion profiles can be attributed to the nature of the composite material itself. FRP profiles are typically made by impregnating continuous fibers, such as fiberglass or carbon fiber, with a polymer resin matrix. This combination of fibers and resin creates a material that exhibits high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue properties. The fiber reinforcement in FRP profiles provides them with inherent resistance against fatigue. The continuous fibers distribute and absorb stresses more evenly, preventing the formation and propagation of cracks or defects that can lead to failure. Additionally, the polymer resin matrix acts as a protective layer, shielding the embedded fibers from environmental factors that could degrade their fatigue resistance. The fatigue resistance of FRP pultrusion profiles can be further enhanced through specific design considerations and manufacturing techniques. For example, the orientation and arrangement of the fibers within the profile can be optimized to improve the load-carrying capacity and fatigue life. Additionally, the use of advanced resin systems and manufacturing processes can result in improved interfacial bonding between the fibers and the matrix, further enhancing the fatigue resistance. Overall, FRP pultrusion profiles are renowned for their exceptional fatigue resistance. This makes them an ideal choice for applications that require long-term durability and resistance to cyclic loading, such as infrastructure components, aerospace structures, marine applications, and sporting goods.

- Q:How do FRP pultrusion profiles perform in chemical processing plants?

- FRP pultrusion profiles perform exceptionally well in chemical processing plants. They are highly resistant to corrosion, chemicals, and extreme temperatures, making them an ideal choice for various applications. Their superior strength-to-weight ratio allows for easy installation and reduces maintenance costs. Additionally, FRP profiles offer excellent electrical insulation properties, making them safe and reliable in hazardous environments. Overall, FRP pultrusion profiles are a reliable and durable solution for chemical processing plants.

- Q:Can FRP pultrusion profiles be used in the construction of elevated walkways?

- FRP pultrusion profiles have the capability to be utilized in the construction of elevated walkways. These profiles are not only lightweight, but they also possess significant strength, rendering them an optimal selection for the creation of walkways that are durable and have longevity, even when subjected to heavy foot traffic. Additionally, they provide exceptional resistance to corrosion, making them suitable for outdoor applications where exposure to moisture, chemicals, and UV radiation is a concern. Moreover, due to their high strength-to-weight ratios, FRP pultrusion profiles can be easily installed and lessen the structural load on the supporting elements. Furthermore, the non-conductive nature of FRP profiles make them a safer alternative for walkways in areas that are prone to electrical hazards. In summary, the advantages offered by FRP pultrusion profiles make them highly suitable for the construction of elevated walkways.

- Q:Are FRP pultrusion profiles resistant to hydrochloric acid?

- Yes, FRP pultrusion profiles are generally resistant to hydrochloric acid due to the corrosion-resistant properties of the fiberglass reinforcement and the resin matrix used in their construction. However, the specific resistance may vary depending on the composition and concentration of the acid, and it is recommended to consult the manufacturer's specifications for detailed information regarding chemical resistance.

- Q:How do FRP pultrusion profiles withstand extreme temperatures?

- FRP pultrusion profiles are able to withstand extreme temperatures due to the inherent properties of the materials used in their construction. The combination of reinforced fibers, such as fiberglass, and a thermosetting resin matrix creates a composite material with high thermal stability. This enables the profiles to maintain their structural integrity and dimensional stability even under extreme heat or cold conditions. Additionally, the design and manufacturing process of FRP pultrusion profiles ensures that the materials are evenly distributed and tightly bonded, further enhancing their ability to withstand temperature variations without compromising their strength.

- Q:Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q:Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q:How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles have demonstrated promising performance in electrical grounding systems, showcasing their potential. These profiles consist of a combination of fibers, such as glass or carbon, and a polymer resin matrix. This unique composition provides them with exceptional attributes, including high strength, durability, and resistance to corrosion. One noteworthy advantage of FRP pultrusion profiles in electrical grounding systems lies in their remarkable electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles possess a significantly high resistance to electrical current. This aspect renders them ideal for applications where electrical isolation is paramount. By doing so, they effectively mitigate the risks associated with electrical shock hazards and diminish the potential for short circuits. Furthermore, FRP pultrusion profiles offer superior mechanical strength while remaining lightweight. Consequently, they are easy to handle and install, leading to reduced labor costs and time consumption. Additionally, these profiles exhibit resistance against UV radiation, chemicals, and moisture, ensuring their long-term performance and durability across various environmental conditions. Another advantageous attribute of FRP pultrusion profiles pertains to their corrosion resistance. Unlike metals, which are susceptible to rust and deterioration over time, FRP profiles remain immune to corrosion. This quality renders them highly suitable for deployment in harsh or corrosive environments, guaranteeing the longevity and reliability of the electrical grounding system. Moreover, FRP pultrusion profiles exhibit non-magnetic properties, presenting an advantage in situations where minimizing or eliminating magnetic interference is crucial. This characteristic effectively prevents any disturbances to sensitive electrical equipment, thereby ensuring accurate electrical measurements. In conclusion, FRP pultrusion profiles offer a multitude of advantages in electrical grounding systems. Their exceptional electrical insulation properties, impressive mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for guaranteeing the safety and reliability of electrical grounding.

- Q:What are the different types of FRP pultrusion profiles available?

- There are several different types of FRP (Fiber Reinforced Polymer) pultrusion profiles available, each designed to meet specific application requirements and performance criteria. Some of the most common types include: 1. Standard shapes: These profiles are commonly used in various industries and applications. They come in a range of sizes and shapes, such as round tubes, square tubes, rectangular tubes, and angles. Standard shapes provide versatility and are suitable for a wide range of structural and non-structural applications. 2. Custom profiles: These profiles are specifically designed and manufactured according to customer specifications. Custom profiles offer greater flexibility in terms of shape, dimensions, and reinforcement options. They are often used in unique or specialized applications where standard shapes may not be suitable. 3. Structural profiles: These profiles are designed to provide high strength and stiffness properties. They are commonly used in load-bearing applications where structural integrity is crucial, such as beams, columns, and trusses. Structural profiles are reinforced with additional fibers to enhance their load-bearing capacity. 4. Electrical profiles: These profiles are designed to have excellent electrical insulation properties. They are commonly used in electrical and electronics applications, such as cable trays, busbars, and insulating supports. Electrical profiles offer high dielectric strength and resistance to electrical conductivity. 5. Environmental profiles: These profiles are specially formulated to resist harsh environmental conditions, such as extreme temperatures, UV radiation, or chemical exposure. They are commonly used in outdoor applications, such as structural supports, handrails, and grating systems. Environmental profiles provide long-term durability and resistance to degradation. 6. Fire-retardant profiles: These profiles are designed to have improved fire resistance properties. They are commonly used in applications where fire safety is a concern, such as building construction, transportation, and aerospace. Fire-retardant profiles are formulated with additives that inhibit flame spread and reduce smoke generation. It is important to note that these are just some of the common types of FRP pultrusion profiles available, and there may be other specialized profiles based on specific industry requirements. The selection of the appropriate profile depends on factors such as the intended application, load requirements, environmental conditions, and regulatory standards.

- Q:What is the lifespan of FRP pultrusion profiles?

- The lifespan of FRP pultrusion profiles may differ depending on various factors. Generally, FRP pultrusion profiles are renowned for their durability and longevity, often having a long lifespan. The quality of materials utilized in constructing FRP pultrusion profiles is a significant factor that influences their lifespan. High-quality FRP materials, including premium resins and strong fibers, tend to have a lengthier lifespan in comparison to lower-quality materials. Furthermore, the lifespan of FRP pultrusion profiles can be affected by the environmental conditions under which they are installed. Exposure to extreme temperatures, moisture, UV radiation, chemicals, and mechanical stresses can all impact the performance and lifespan of FRP profiles. Hence, proper installation and maintenance play a vital role in ensuring their longevity. When FRP pultrusion profiles are designed, manufactured, and installed correctly, they can last anywhere from 25 to 50 years or more. However, it is important to note that this estimate can vary depending on the specific application, level of exposure to harsh conditions, and overall care and maintenance of the profiles over time. To extend the lifespan of FRP pultrusion profiles, regular inspections, cleaning, and necessary repairs are recommended. Seeking advice from manufacturers or industry experts can provide more precise information regarding the anticipated lifespan of FRP profiles in a particular application or environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass FRP Phenolic Molded and Pultruded Grating with Great Shape/Best Sales

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords