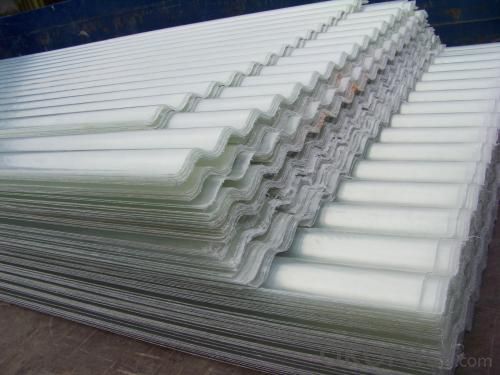

Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Composition | UP-resin system, glass fiber , gel coat or protective film |

Surface | Dupon 20um Film or Gel Coat |

Fiber Content | 25% - 35%, using JUSHI fiber |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm |

Width | Up to 1.35 meter |

Effective temperature | -40℃~ +120℃ |

Light Transmissivity | 3% - 85% |

Length | Customizable, for easy transport, suggest using 5.6m or 11.8m |

Profile | Flat type & corrugated type, LG840, LG900, LG1050 or customizable |

Colors | Clear blue, Light blue, Lake blue, Sky blue, Deep blue, Clear white, Solid white, Gray white, Black, Clear green or Customizable |

PICTURES

- Q:Can FRP roofing panels be used in indoor swimming pools?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in indoor swimming pools. FRP panels are known for their durability, water resistance, and resistance to corrosion, making them a suitable choice for indoor swimming pools. They are also lightweight, easy to install, and have excellent thermal insulation properties. Additionally, FRP panels are resistant to the chemicals used in pool water, which can be corrosive to many other building materials. Overall, FRP roofing panels are a reliable and practical option for indoor swimming pools.

- Q:Do FRP roofing panels require a specific type of gutter system?

- Yes, FRP roofing panels typically require a specific type of gutter system designed to accommodate the unique characteristics of these panels. The gutter system should be designed to effectively handle the water flow and potential expansion and contraction of the FRP roofing panels. Consulting with a professional or the manufacturer of the panels is recommended to determine the most suitable gutter system for FRP roofing panels.

- Q:Can FRP roofing panels be used in military or government buildings?

- Yes, FRP roofing panels can be used in military or government buildings. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, versatility, and low maintenance requirements. These panels offer excellent resistance to harsh weather conditions, UV rays, and chemicals, making them suitable for various applications, including military and government structures. Additionally, FRP panels are lightweight, easy to install, and can provide superior insulation properties, making them an attractive choice for roofing solutions in these types of buildings.

- Q:Are FRP roofing panels resistant to tree damage?

- Yes, FRP roofing panels are generally resistant to tree damage as they are designed to be durable and withstand various external factors. However, the extent of resistance may vary depending on the size and force of the tree's impact.

- Q:Can FRP roofing panels be used for both pitched and flat roofs?

- Both pitched and flat roofs can make use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are adaptable and can suit different roof types and designs. They possess excellent durability, weather resistance, and insulation properties, making them appropriate for residential and commercial purposes. For pitched roofs, FRP roofing panels are typically installed as a covering material over the roof structure. They can be secured using screws or adhesive, providing protection against harsh weather conditions. The pitched design facilitates efficient water drainage, preventing water accumulation and potential leakage. In contrast, FRP roofing panels can also be employed for flat roofs. In this scenario, they are frequently utilized as a waterproofing layer or as part of a multi-layer roofing system. The panels are laid flat and joined together using sealants or overlapping techniques to create a watertight seal. Additionally, FRP panels can be reinforced with extra layers or coatings to enhance their resistance to UV radiation, impact, and other external factors. It is crucial to note that proper installation and compliance with building codes and regulations are essential when using FRP roofing panels. It is advisable to consult with a professional roofing contractor or manufacturer to ensure the panels are correctly installed and suitable for the specific roof type and conditions. In conclusion, FRP roofing panels offer a cost-effective and long-lasting solution for both pitched and flat roofs, making them a popular choice in the construction industry. Their versatility, strength, and ability to withstand harsh weather conditions make them a reliable option for various roof designs and applications.

- Q:How do FRP roofing panels perform in terms of insulation?

- FRP roofing panels have relatively low insulation properties compared to other roofing materials. However, they still provide some level of insulation and can help reduce heat transfer between the interior and exterior of a building.

- Q:Are FRP roofing panels resistant to graffiti removal chemicals?

- FRP roofing panels are typically resistant to graffiti removal chemicals. These panels are made from a reinforced plastic material that is designed to be durable and resistant to various environmental factors, including chemicals. However, it is important to note that the level of resistance may vary depending on the specific brand and quality of the FRP roofing panels. It is advisable to consult the manufacturer's guidelines or contact a professional for specific information on the resistance of the panels to graffiti removal chemicals. Additionally, it is always recommended to test the chemicals on a small, inconspicuous area of the panel before applying it to the entire surface to ensure compatibility and avoid any potential damage.

- Q:Are FRP roofing panels compatible with different roofing adhesives?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels are generally compatible with different roofing adhesives. However, it is important to ensure that the specific adhesive being used is suitable for use with FRP panels. FRP panels are commonly used in roofing applications due to their durability, strength, and resistance to various weather conditions. When it comes to adhesives, there are different types available, such as epoxy adhesives, polyurethane adhesives, and silicone adhesives. Before applying any adhesive to FRP roofing panels, it is crucial to read the manufacturer's instructions and recommendations. The manufacturer will typically provide guidance on which adhesive types are compatible with their specific FRP panels. Adhering to the manufacturer's recommendations will ensure a proper bond between the panels and the roofing substrate. Additionally, it is important to consider the environmental conditions in which the roofing panels will be installed. Extreme temperatures, humidity, and UV exposure can affect the performance of the adhesive. Therefore, it is essential to choose an adhesive that is designed to withstand the specific environmental conditions of the roofing project. In summary, FRP roofing panels can be compatible with different roofing adhesives, but it is crucial to follow the manufacturer's recommendations and choose an adhesive that is suitable for FRP panels and the specific environmental conditions of the project.

- Q:Are FRP roofing panels resistant to extreme temperatures or thermal expansion?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to extreme temperatures and thermal expansion. The unique composition of FRP panels allows them to withstand both hot and cold climates without warping, cracking, or experiencing significant expansion or contraction. This makes FRP roofing panels a reliable and durable choice for various environments and weather conditions.

- Q:Can FRP roofing panels be used for cold storage facilities?

- FRP roofing panels are capable of being utilized in cold storage facilities, providing exceptional insulation, durability, and resistance to corrosion. These qualities render them appropriate for environments necessitating temperature regulation, like cold storage facilities. The effective thermal insulation offered by FRP roofing panels effectively hinders the transfer of heat between the interior and exterior of the facility. Consequently, a consistent and regulated temperature is maintained within the cold storage facility, guaranteeing that perishable items are preserved at the desired temperature. Furthermore, FRP panels exhibit moisture resistance and the ability to endure low temperatures, making them an optimal selection for cold storage purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords