Extruded Polystyrene XPS Tile Backer Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation & waterproofing solutions - CMAX Extruded Polystyrene XPS Tile Backer Board

Product name :

CMAX board (as known as construction board, tile backer board, insulation backer board, waterproof backer board, wet room backer board, XPS board.)

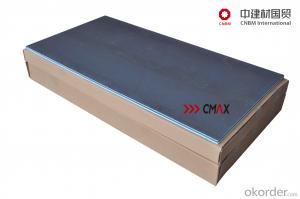

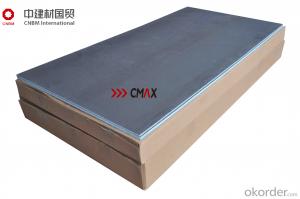

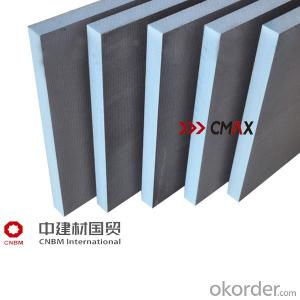

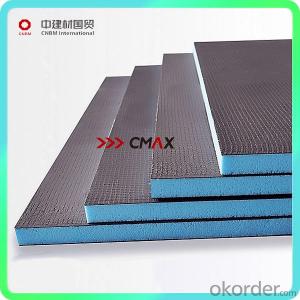

Product structure of Extruded Polystyrene XPS Tile Backer Board:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

Outstanding characteristics of Extruded Polystyrene XPS Tile Backer Board:

Both insulation and waterproof.

Product appearance of Extruded Polystyrene XPS Tile Backer Board:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range:

50 to +80 °C

Standard dimensions and weight:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to FireExtruded Polystyrene XPS Tile Backer Board:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment Extruded Polystyrene XPS Tile Backer Board:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration Extruded Polystyrene XPS Tile Backer Board:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications Extruded Polystyrene XPS Tile Backer Board:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications Extruded Polystyrene XPS Tile Backer Board:

Other places to be insulated and waterproofed.

Applications Extruded Polystyrene XPS Tile Backer Board:

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

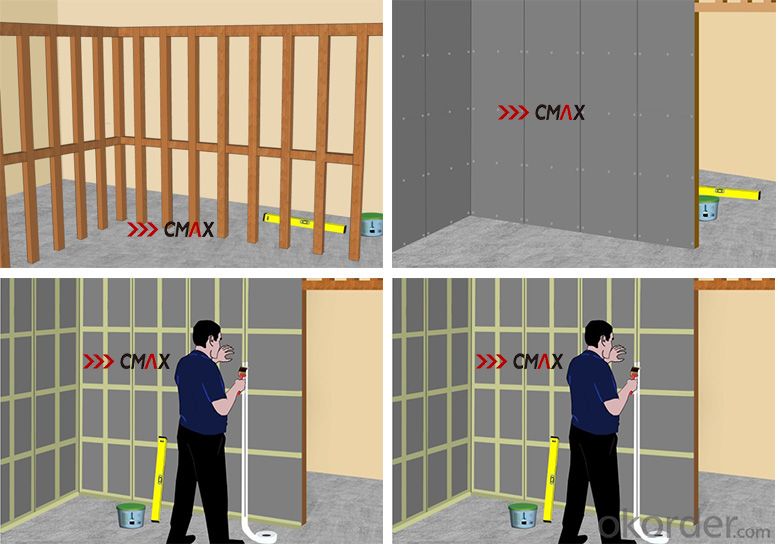

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

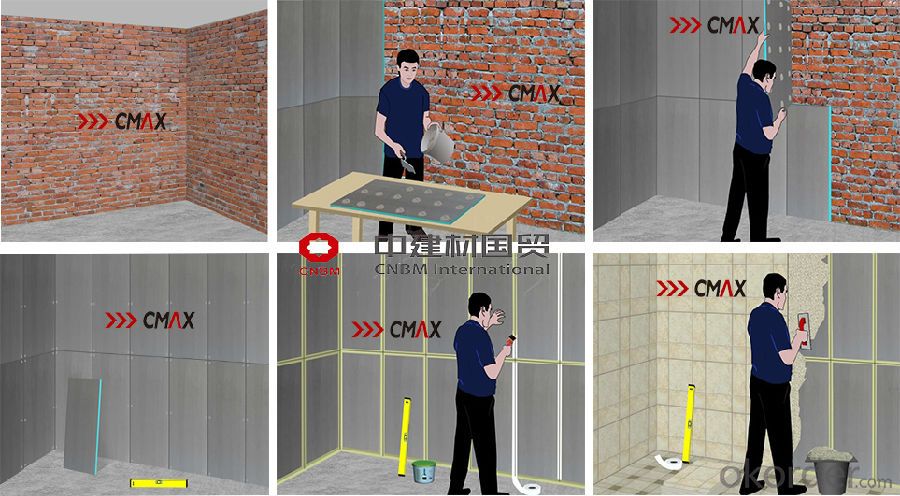

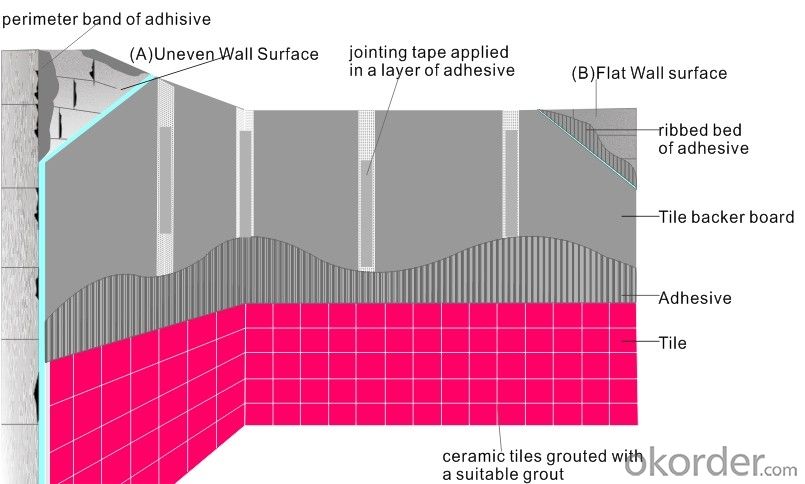

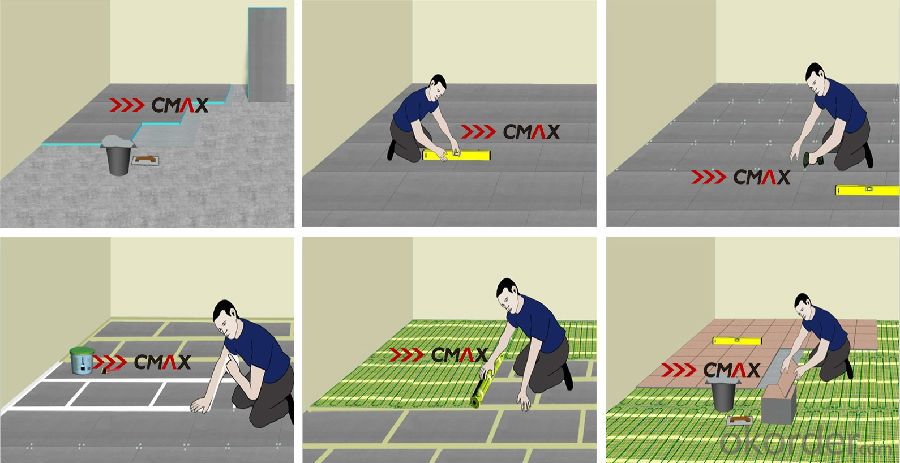

Fixing:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels Extruded Polystyrene XPS Tile Backer Board:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q:What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- The key indicator of good or bad weight is the weight, that is, the weight per cubic meter. Big enough.

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- In when Edison in the study of incandescent bulbs, in the white hot filament inserted between a metal sheet

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- That is, can be in the farthest bowel forging forging treadmill punch fist away from the pull up the most important things tower crane top of the car can move back and forth he moved to the farthest place to pull up the heaviest weight is slightly! The

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Brothers asked, what is the price of extruded board in 2008 to do a report need to trouble to tell the next thank you

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q:25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- But its assembly is more complex and is not conducive to high-level construction, safety performance Dingzao cut to cut the salt tax is also poor, if the assembly is very easy to accident, and susceptible to natural factors and reduce its safety, As more and more emphasis on the protection of green today, it is bound to be replaced by steel scaffolding fastener type steel scaffolding with easy processing, easy handling, versatility and other advantages, is currently the largest use of China, the most common use of a scaffolding, but this scaffolding security is equally poor, the construction efficiency Low, scaffolding maximum erection height of 33 meters, can not meet the development needs of high-rise building construction bowl button assembly disassembly is relatively simple, the assembly performance is also good, more in the United States, China seems to use is not very wide But personally think that the future bowl button scaffolding will certainly be popular, there are prospects aluminum scaffolding is mainly lightweight, corrosion-resistant But not a high degree of construction, can not be high-level construction the disc does not seem to use the fastener with the bowl button type, universal joint do not understand So, personally think that in China fastening scaffolding or the mainstream, bowl button-style prospects are good

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruded Polystyrene XPS Tile Backer Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords