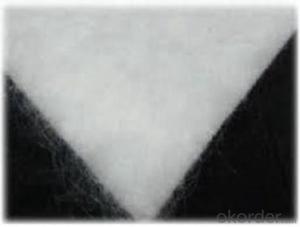

Excellent Water Permeability PP Non-woven Geotextiles CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Features:

•

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

•Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

•Manufactured using a randomly orientated web to proide completely isotropic properties,ensuring that high strength is not limited to a single direction.

•Excellent uniformity with high permeability and low pore size for soil filtration.

•Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

•100% polypropylene or polyester staple fibers ,needle punched and random network formation.

•UV and rot resistant and biological degradation resistant.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in stormwater management systems?

- Yes, geotextiles can be used in stormwater management systems. Geotextiles are often used to enhance filtration and separation in stormwater management applications, helping to control erosion and retain sediment within the system. They can be used in various components of stormwater systems such as sediment basins, retention ponds, and biofiltration systems to improve their effectiveness and longevity.

- Q:What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on factors such as the material used, the specific application, and the environmental conditions. However, on average, geotextiles are designed to have a lifespan of at least 25 to 30 years.

- Q:What are the factors affecting the selection of geotextiles?

- The factors affecting the selection of geotextiles include the type and severity of the application, desired performance characteristics such as strength and filtration properties, site conditions such as soil type and slope stability, environmental considerations such as chemical resistance and durability, and cost-effectiveness.

- Q:How do geotextiles help with moisture management in construction projects?

- Geotextiles help with moisture management in construction projects by acting as a barrier that allows water to pass through while preventing soil erosion. They can be used to separate different layers of soil or aggregates, preventing the mixing of fine and coarse materials and ensuring proper drainage. Additionally, geotextiles can help control groundwater by providing filtration and reducing the risk of water accumulation, ultimately enhancing the overall stability and durability of construction projects.

- Q:How do geotextiles aid in the reduction of differential settlement?

- Geotextiles aid in the reduction of differential settlement by providing a stable and uniform foundation for the soil. They distribute and equalize the load across the soil, preventing differential settlement and ensuring the overall stability of the structure. Additionally, geotextiles can help in reinforcing weak soils, improving their bearing capacity and reducing the potential for differential settlement.

- Q:Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q:Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles provide filtration and separation functions, allowing for efficient dewatering of mine tailings by separating solids from liquids. They can help in reducing the moisture content of the tailings, making them easier to handle and manage. Geotextiles also aid in improving the stability and strength of the dewatered tailings, minimizing the risk of slope failures or environmental contamination.

- Q:What are the key considerations for geotextile installation in high wind areas?

- There are several key considerations for geotextile installation in high wind areas. First and foremost, it is important to select a geotextile material that is specifically designed to withstand high wind loads. This may involve choosing a heavy-duty geotextile with a high tensile strength and puncture resistance. Additionally, proper anchoring is crucial in high wind areas to prevent the geotextile from being lifted or displaced. This may involve using batten bars, sandbags, or other secure anchoring methods. It is also important to ensure proper overlap and seam construction to maintain the integrity of the geotextile system. Regular inspections and maintenance should be conducted to identify any potential damage or issues caused by the high wind conditions and address them promptly. Overall, careful planning and implementation are essential to ensure the effectiveness and longevity of geotextile installation in high wind areas.

- Q:How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

- Q:How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles help with soil confinement in erosion control bags by providing a permeable barrier that retains the soil particles while allowing water to pass through. They prevent soil erosion by reinforcing the bags and stabilizing the soil, preventing it from being washed away by water or wind.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Excellent Water Permeability PP Non-woven Geotextiles CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords