Equal angle steel for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

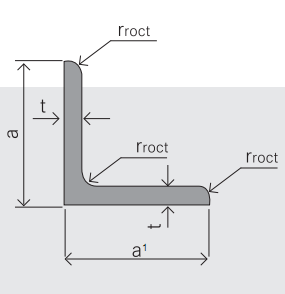

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

4.Sizes:

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

- Q:How do you prevent corrosion between steel angles and other materials?

- One effective way to prevent corrosion between steel angles and other materials is by applying a protective coating or paint to the surface of the steel. This coating acts as a barrier, preventing direct contact between the steel and other elements that may cause corrosion, such as moisture or chemicals. Additionally, ensuring proper ventilation and drainage around the steel angles can help prevent moisture buildup, which is a common cause of corrosion. Regular inspection and maintenance, including cleaning and repairing any damaged coatings, can also help prevent corrosion in the long run.

- Q:Can steel angles be used for platform structures?

- Yes, steel angles can be used for platform structures. Steel angles are commonly used in construction for their strength, durability, and versatility. They provide structural support and stability to various types of platforms, including elevated walkways, mezzanines, catwalks, and scaffolding. Steel angles offer excellent load-bearing capacity and can withstand heavy loads, making them suitable for platform structures that require a high level of strength and stability. Additionally, steel angles can be easily fabricated and joined together, allowing for efficient construction and customization of platform structures.

- Q:What are the different types of steel angles used in agricultural applications?

- In agricultural applications, various types of steel angles are commonly utilized. These angles serve different purposes and possess distinct features. Here are some examples: 1. Equal Angle: This steel angle boasts equal sides and is frequently employed in agricultural structures like barns and sheds for structural reinforcement. Its stability and strength make it suitable for supporting heavy loads. 2. Unequal Angle: As the name implies, this steel angle has sides of unequal lengths. It finds widespread use in agricultural machinery, such as tractor attachments and implements. The uneven sides allow for precise positioning and attachment of various components. 3. Lipped Angle: Similar to equal angles, lipped angles have an added lip or flange on one side. This lip enhances support and rigidity, making it ideal for agricultural purposes that demand extra strength, such as fencing and gate posts. 4. Slotted Angle: Slotted angles are highly adaptable and can be adjusted to different angles as required. They are commonly employed in agricultural shelving systems, enabling farmers to create customized storage solutions for tools, equipment, and supplies. The slots present in these angles provide flexibility for modifying shelf heights. 5. Rolled Steel Angle: Rolled steel angles are created by rolling steel into angle-shaped sections. They are extensively used in agricultural construction for bracing, supporting beams, and framing. Rolled steel angles offer exceptional strength and durability, rendering them suitable for demanding agricultural environments. Each type of steel angle possesses unique characteristics and advantages. The selection of the appropriate angle depends on the specific agricultural application and the desired level of strength and support. Factors such as load-bearing capacity, durability, and resistance to corrosion should be carefully considered when choosing the suitable steel angle for agricultural use.

- Q:Do steel angles require any special maintenance?

- Yes, steel angles require regular maintenance to prevent rusting and corrosion. This includes cleaning, inspecting for any damage or wear, and applying protective coatings or paints as needed. Additionally, proper storage and handling practices should be followed to avoid any potential damage to the steel angles.

- Q:How do you join steel angles together?

- There exists a range of methods for joining steel angles together, depending on the specific circumstances and requirements. Presented here are some commonly utilized techniques: 1. Welding: A popular and effective method for joining steel angles is welding. This process involves melting the edges of the angles and fusing them together using a welding machine. Welding yields robust and enduring connections, albeit necessitating skilled personnel and adherence to safety precautions. 2. Bolting: Another commonly employed method for joining steel angles is bolting. This approach entails utilizing bolts, nuts, and washers to connect the angles. Bolting provides a secure connection and allows for disassembly, if necessary. It is relatively straightforward and does not demand specialized equipment. 3. Riveting: A traditional method for connecting steel angles is riveting. This method necessitates drilling holes in the angles and using a rivet gun to secure the rivets. Riveting results in a sturdy and permanent connection. 4. Adhesive bonding: Adhesive bonding involves using a potent adhesive to join steel angles. This method is suitable for lightweight applications and offers the advantage of not requiring heat or specialized equipment. However, it may not be ideal for heavy-duty or high-stress applications. When selecting the appropriate method for joining steel angles, it is crucial to consider factors such as load-bearing capacity, structural integrity, aesthetic requirements, and environmental conditions. Consulting with a professional engineer or fabricator can further ensure the selection of the most suitable joining method for one's specific needs.

- Q:Can steel angles be used for mezzanine floors?

- Yes, steel angles can be used for mezzanine floors. Steel angles are commonly used as structural components in construction, including for mezzanine floors. They provide stability and support to the structure, allowing for the creation of additional floor space. Steel angles are strong and durable, making them suitable for supporting heavy loads and ensuring the safety of the mezzanine floor. Additionally, steel angles can be easily fabricated and installed, making them a cost-effective choice for constructing mezzanine floors.

- Q:How do you calculate the effective length of a steel angle?

- When calculating the effective length of a steel angle, there are two main factors to consider: the actual length of the angle and the stability of its supported members. To begin, you must determine the actual length of the steel angle. This can be done by physically measuring it or referring to the manufacturer's specifications. It is crucial to have the precise length value for the calculation. Next, evaluate the stability of the angle's supported members. The effective length of the angle is influenced by the specific conditions in which it is being used and supported. There are three primary support conditions to take into account: pinned-pinned, fixed-fixed, and fixed-pinned. In the case of a pinned-pinned support condition, the effective length is equal to the actual length of the angle. This condition assumes that both ends of the angle can freely rotate, allowing the full length to effectively resist applied loads. For a fixed-fixed support condition, the effective length is typically considered as 0.7 times the actual length. This condition assumes that both ends of the angle are rigidly connected, resulting in a reduced effective length due to the increased stiffness of the entire system. In a fixed-pinned support condition, the effective length is usually 0.85 times the actual length. In this scenario, one end of the angle is fixed while the other end can rotate freely, leading to a decreased effective length compared to the actual length. Accurately determining the support conditions of the steel angle is essential for correctly calculating its effective length. In addition, a comprehensive analysis of the angle's behavior should consider other factors such as its material properties, cross-section, and loading conditions.

- Q:How do you protect steel angles from corrosion?

- Steel angles can be protected from corrosion in various ways. One of the most commonly used methods is the application of a protective coating, such as paint or a specialized corrosion-resistant coating. This creates a barrier between the steel and its surroundings, preventing moisture and corrosive agents from reaching the metal surface. Another effective approach is to galvanize the steel angles. This involves coating the steel with a layer of zinc, which acts as a sacrificial anode. Instead of the steel corroding, the zinc sacrifices itself, providing long-lasting protection against rust and corrosion. Regular maintenance is also crucial for corrosion prevention. It is important to regularly clean the surface to remove dirt, debris, and other contaminants that can accelerate corrosion. Additionally, inspecting the steel angles for any signs of damage or wear and promptly repairing or replacing any compromised areas can help stop corrosion from spreading. Using stainless steel angles is another option for corrosion protection. Stainless steel contains a significant amount of chromium, which forms a passive layer on the surface when exposed to oxygen. This passive layer acts as a protective barrier against corrosion, making stainless steel angles highly resistant to rust and corrosion in various environments. Lastly, ensuring proper drainage and ventilation around steel angles is essential to prevent the accumulation of moisture, which can contribute to corrosion. By employing proper design and installation techniques that minimize contact with water and moisture, the lifespan of steel angles can be significantly extended, and the risk of corrosion reduced.

- Q:Can steel angles be used in mining or offshore applications?

- Yes, steel angles can be used in mining or offshore applications. They are commonly used in these industries due to their high strength, durability, and corrosion resistance properties. Steel angles are versatile and can be utilized for various purposes such as structural support, framing, and bracing in mining operations or offshore structures.

- Q:Are steel angles resistant to chemical corrosion?

- Steel angles have some resistance to chemical corrosion. Although steel is generally strong and durable, it can still corrode in the presence of certain chemicals and corrosive environments. However, steel angles are often treated or coated with protective materials like galvanization, which greatly improves their resistance to chemical corrosion. Galvanized steel angles have a zinc layer on their surface that acts as a barrier against corrosive substances. This coating helps prevent direct contact between the steel and chemicals, reducing the risk of corrosion. It's important to note, though, that the level of resistance may vary depending on the specific chemical, as well as the duration and intensity of exposure. To ensure long-term corrosion resistance, regular maintenance and inspection of steel angles are necessary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Equal angle steel for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords