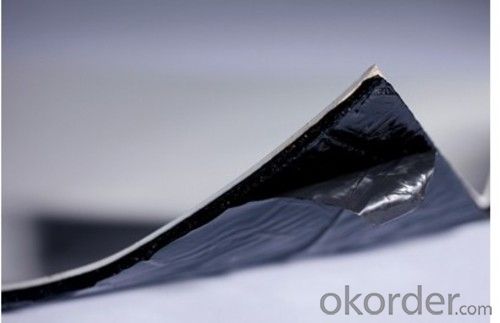

EPDM Waterproofing Rubber Membrane Used in Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description:

EPDM waterproofing membrane is the modified materials. They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability . Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

Product Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Applicable scope:

1.0mm 1.2mm 1.5mm 1.8mm 2.0mm EPDM waterproof membrane is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:How to choose waterproof membrane

- Second, from the fetal base to identify the quality of the coil Generally from the product on the cross-section of visual inspection, the specific method can be purchased products by hand to tear it, observe the cross-section exposed fetal fiber, composite tires tear after the section of the grid cloth ribs exposed, this time It can be concluded that the product must be a composite tire coil, what kind of composite tire membrane with physical properties test - soluble content test to observe the exposed fetal base. And simple polyester tires, glass fiber tires after tearing the section only polyester or fiberglass fiber exposed.

- Q:SBS Shale Waterproof Coil

- Features: low temperature flexibility is good, to -25 ℃ does not crack; high heat resistance, 90 ℃ does not flow. Good extension performance, long service life, simple construction, small pollution and so on. Products for Ⅰ, Ⅱ level building waterproofing works, especially for low temperature cold areas and structural deformation of the frequent building waterproofing works.

- Q:Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. In fact, it is highly recommended to use a waterproofing membrane in such areas to protect buildings and structures from potential water damage caused by earthquakes. Waterproofing membranes are designed to create a barrier against water infiltration, which can be crucial in preventing structural damage and maintaining the integrity of a building during seismic events. Additionally, these membranes can also provide some level of flexibility and elasticity, which can help absorb and distribute the forces exerted during an earthquake, reducing the risk of cracks and leaks. However, it is important to ensure that the waterproofing membrane used is specifically designed and tested to meet the requirements of earthquake-prone areas, considering factors such as the intensity and frequency of seismic activity in the region. Consulting with a structural engineer or a waterproofing specialist is highly recommended to determine the most suitable waterproofing system for earthquake-prone areas.

- Q:Can a waterproofing membrane be applied on top of existing coatings?

- Indeed, applying a waterproofing membrane over existing coatings can be done. However, there are several factors that must be taken into consideration beforehand. Firstly, the condition and adherence of the current coating should be evaluated to guarantee that it is in good shape and capable of serving as a suitable base for the waterproofing membrane. If the existing coating is loose, damaged, or incompatible with the membrane, it might be necessary to remove or repair it prior to applying the membrane. Moreover, ensuring compatibility between the existing coating and the waterproofing membrane is crucial. Different types of coatings and membranes may not adhere properly to one another, resulting in inadequate performance or failure. It is essential to consult the manufacturer's recommendations and seek professional advice to ensure that the existing coating and the chosen waterproofing membrane are compatible. Furthermore, proper surface preparation is essential for the successful application of a waterproofing membrane over existing coatings. The surface must be thoroughly cleaned, devoid of dirt, debris, and any loose or flaking coating. Additionally, any cracks, holes, or imperfections in the existing coating should be repaired prior to applying the membrane. In conclusion, although it is possible to apply a waterproofing membrane over existing coatings, it is essential to evaluate the condition and adherence of the existing coating, ensure compatibility between the coating and membrane, and adequately prepare the surface for a successful application. Seeking professional advice and adhering to the manufacturer's recommendations are highly recommended in order to ensure the effectiveness and longevity of the waterproofing system.

- Q:Are waterproofing membranes resistant to extreme weather conditions?

- Yes, waterproofing membranes are designed to be highly resistant to extreme weather conditions. They are engineered to withstand heavy rain, snow, high winds, and temperature fluctuations without compromising their effectiveness. They provide a durable barrier against moisture, protecting structures from water damage, leaks, and potential structural issues caused by extreme weather.

- Q:Can waterproofing membranes be used on precast concrete panels?

- Yes, waterproofing membranes can be used on precast concrete panels. Precast concrete panels can be susceptible to water penetration, which can lead to moisture damage and deterioration of the concrete. Waterproofing membranes are effective in preventing water infiltration by creating a barrier between the concrete surface and the external environment. These membranes are typically applied to the exterior surface of the precast panels, forming a protective layer that prevents water from seeping through the concrete. By using waterproofing membranes, precast concrete panels can be made more durable, longer-lasting, and resistant to moisture-related issues.

- Q:Does a waterproofing membrane prevent water damage to building materials?

- A waterproofing membrane is specifically designed to shield building materials from water damage. Its purpose is to act as a barrier, preventing water from infiltrating the structure and causing harm. Typically, the membrane is applied to areas prone to water intrusion, such as roofs, basements, and foundations. By creating a watertight seal, it effectively stops water from seeping through and harming the building materials. This safeguard is essential in maintaining the structure's integrity and preventing issues like mold growth, rot, and material decay. However, it's crucial to acknowledge that the effectiveness of a waterproofing membrane can vary based on the product's quality and proper installation. Regular maintenance and inspections are also necessary to ensure the membrane remains intact and continues to safeguard against water damage.

- Q:Can a waterproofing membrane be used on tunnels with electrical installations?

- Yes, a waterproofing membrane can be used on tunnels with electrical installations. These membranes are designed to provide a protective barrier against water ingress, ensuring the safety and functionality of electrical installations in tunnels.

- Q:Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, it is important to follow the manufacturer's guidelines and use products specifically designed for cold weather applications. Cold weather may affect the curing time of the membrane, so it is recommended to take necessary precautions and allow sufficient time for proper curing to ensure the effectiveness of the waterproofing.

- Q:Can a waterproofing membrane be used in fountains or water features?

- Yes, a waterproofing membrane can be used in fountains or water features. Waterproofing membranes are designed to create a barrier that prevents water from seeping through, making them ideal for applications where water containment is essential, such as fountains or water features.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Rubber Membrane Used in Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords