EPDM Waterproofing Roofing Membrane with 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

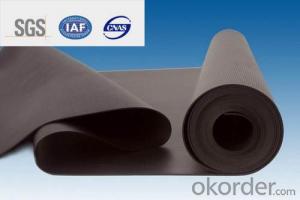

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Can a waterproofing membrane be used on storage tanks?

- Yes, a waterproofing membrane can be used on storage tanks. Waterproofing membranes are designed to create a barrier that prevents water or other liquids from penetrating through the surface they are applied to. When applied to storage tanks, these membranes can provide protection against leaks, corrosion, and damage caused by moisture. They are commonly used in various industries, including oil and gas, chemical, and water treatment, to ensure the integrity and longevity of storage tanks. Additionally, waterproofing membranes can be tailored to meet specific requirements, such as resistance to chemicals, UV exposure, or high temperatures, making them suitable for a wide range of storage tank applications.

- Q:Are waterproofing membranes resistant to earthquake movements?

- Waterproofing membranes are designed to prevent the intrusion of water and moisture into structures, such as buildings and basements. While they are highly effective in protecting against water damage, they are not specifically designed to resist or withstand earthquake movements. Earthquakes involve the shaking and movement of the ground, which can exert significant forces on structures. Waterproofing membranes are not typically engineered to absorb or distribute these forces in the same way as seismic-resistant materials or building techniques. However, it is worth noting that some waterproofing systems may have a certain degree of flexibility or elasticity, which could potentially provide some resistance to minor ground movements during an earthquake. These properties may help the membrane to maintain its integrity and prevent water intrusion in the event of slight shifting or settling. Ultimately, when it comes to earthquake resistance, it is crucial to employ specialized seismic design principles and techniques that are appropriate for the specific location and building requirements. Waterproofing membranes should be used in conjunction with these seismic-resistant measures to ensure the overall structural integrity and safety of a building during seismic events.

- Q:Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Yes, a waterproofing membrane does require special considerations for installation in high-humidity areas. High humidity can increase the moisture levels that the membrane is exposed to, potentially affecting its performance and durability. It is important to choose a membrane specifically designed for high-humidity environments and follow proper installation techniques to ensure effective moisture protection. Additionally, regular inspections and maintenance should be conducted to prevent any potential damage or deterioration caused by the high humidity.

- Q:Can a waterproofing membrane be used for foundation walls and footings?

- Yes, a waterproofing membrane can be used for foundation walls and footings. A waterproofing membrane is a thin layer of material, typically made of rubberized asphalt or polymer-modified bitumen, that is applied to the exterior surface of foundation walls and footings to prevent water penetration. It acts as a barrier, preventing water from seeping into the foundation and causing moisture-related issues such as dampness, mold, and structural damage. The waterproofing membrane is typically applied to the foundation walls and footings during the construction phase, either before or after the concrete is poured. It is important to ensure that the membrane is properly installed and sealed to provide effective waterproofing. The membrane is also commonly combined with other waterproofing techniques such as drainage systems and sump pumps to provide comprehensive protection against water intrusion. Using a waterproofing membrane for foundation walls and footings is a common practice in construction, especially in areas with high water tables or heavy rainfall. It is an effective and reliable method to prevent water damage and increase the longevity of the foundation. Properly waterproofing the foundation walls and footings is essential for maintaining a dry and structurally sound building.

- Q:Can a waterproofing membrane be used for planter boxes or green roofs?

- Certainly, planter boxes or green roofs can benefit from the utilization of a waterproofing membrane. It is strongly advised to implement a waterproofing membrane in these scenarios in order to avoid any water seepage or harm to the underlying structure. Essentially acting as a safeguard, the waterproofing membrane serves to prevent water infiltration into the planter boxes or green roofs, therefore preventing potential complications like decay, mold, or structural deterioration. By skillfully sealing the area, the waterproofing membrane guarantees that the water remains within the designated area, which in turn fosters robust plant growth and safeguards the structural stability.

- Q:Can a waterproofing membrane be used in areas with high water pressure?

- Indeed, areas with high water pressure can benefit from the use of a waterproofing membrane. These membranes are engineered to endure and repel water infiltration, rendering them suitable for locations with elevated water pressure. Typically composed of robust materials like rubber, PVC, or bitumen, these membranes possess exceptional durability and superior waterproofing properties. Furthermore, their strength and resistance to water pressure can be augmented by reinforcing them with additional layers or fabrics. However, to guarantee their effectiveness in high water pressure scenarios, it is crucial to properly install the waterproofing membrane and ensure it meets the area's specific requirements. Seeking professional advice and adhering to the manufacturer's guidelines are highly advised to ensure optimal performance in these conditions.

- Q:Can a waterproofing membrane be used for zoos or aquariums?

- Zoos or aquariums can definitely utilize waterproofing membranes. These membranes are specifically designed to create a protective barrier against water infiltration, making them an excellent choice for preventing water damage and leakage in such environments. They can be applied to different surfaces, such as concrete or steel, to establish a watertight seal and prevent water from seeping into the structure or habitat. Aquariums often rely on waterproofing membranes to ensure that their tanks remain completely watertight and free from leaks, as this is crucial for the well-being of the aquatic animals. Similarly, in zoos, waterproofing membranes can be applied to animal enclosures or exhibit areas to safeguard the structures from water damage and uphold a safe and healthy environment for the animals. Moreover, these membranes possess resistance against various chemicals and can withstand harsh conditions, making them an excellent safeguard against potential chemical spills. All in all, waterproofing membranes are a highly suitable option for zoos or aquariums, as they offer an effective solution for preserving the integrity of the structures and habitats, averting water damage, and ensuring the safety and well-being of the animals.

- Q:Can a waterproofing membrane be installed underneath tile or other flooring materials?

- Certainly, tile or other flooring materials can have a waterproofing membrane installed underneath them. It is strongly advised to utilize a waterproofing membrane in wet areas like bathrooms, kitchens, or laundry rooms as a preventive measure against water damage and mold growth. The membrane functions as a shield separating the subfloor and the flooring material, effectively preventing any water or moisture from infiltrating and causing harm. Additionally, it offers an extra level of safeguarding against potential leaks or spills that might happen over time. By installing a waterproofing membrane, you can guarantee the durability, longevity, and absence of any water-related complications in your flooring.

- Q:Does a waterproofing membrane require any maintenance?

- Yes, a waterproofing membrane typically requires some maintenance to ensure its effectiveness over time. Regular inspections, repairs, and cleaning are recommended to prevent any damage or deterioration.

- Q:Can a waterproofing membrane be used on tunnels with historical significance?

- Yes, a waterproofing membrane can be used on tunnels with historical significance. The membrane can help protect the tunnel from water damage and prevent further deterioration, ensuring the preservation of its historical significance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproofing Roofing Membrane with 2.0mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords